How to Generate Gerber Files in PCB Layout for Beginners?

By:PCBBUY 11/16/2021 08:58

Many are unaware of the most common problems with Gerber files, but it is immensely useful to know about them when entering into the PCB design and production process. When you use Gerber to design PCB, it will be the very essential first step during the PCB manufacturing process. And there will be also some errors during this step. But without errors is easier than it may seem. Gerber files are digital blueprints for your PCB. Gerber files are like PDFs for electronics manufacturing industry.

Are you a beginner of PCB layout? If you are going to learn the methods of create Gerber files, please check and read the content below for more in this passage.

If you want to order PCB product, please check and custom your order online.

What is the basic information of Gerber files in PCB layout?

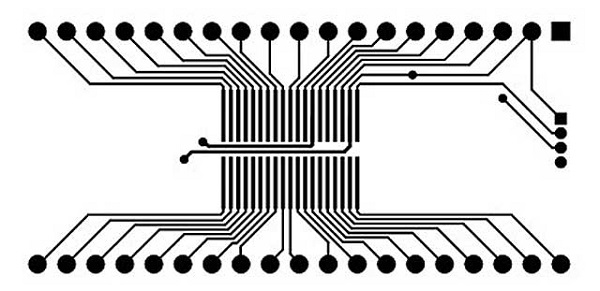

A Gerber, or Gerber Extended File, is a standard file format used in the electronics industry to store and communicate design blueprints. They're often used to convey information regarding manufacturing specifications of printed circuit boards. At their core, Gerber files are like PDFs for electronics manufacturing industry. Have you ever gone through an X-ray inspection in a hospital when you suffered from a fracture of bones? You can totally imagine a Gerber file as an X-ray image of a real PCB. An X-ray image just tells how your bones are organized while a Gerber file indicates how circuits are led in a PCB.

What is the role of Gerber files in PCB layout?

Gerber file history can be traced back to the needs of the original vector photoplotters. In order to give the plotter its instructions, a Gerber file contained minimal plotter configuration information, and X/Y coordinates followed by a flash or drawing command and which aperture position to use. The Gerber data has increased in functionality over the year; it now includes additional configuration information as well as macro and aperture definitions.

The PCB manufacturing technology used today has come a long way over the past decades. Previously, vector photoplotters were used to create the tooling film used in the PCB manufacturing process. There was only a minimal set of apertures available and designers had to be creative in restricting their flashes and lines to only the apertures that were available to them.

What are the features of generating Gerber files in PCB layout?

· Configuration factors

· Macro and aperture measurements

· Draw and flash command codes

· XY Coordinate settings.

Again, there is a Gerber file for every drill span and image layer of the PCB found in a single template. Sometimes, you can send over eight documents for a two-layered board to your PCB manufacturer. They may comprise:

· A picture of the copper layer to be placed on the lower part of the board.

· A picture of the copper layer to be placed on the upper part of the board.

There would be two templates for the solder mask and silkscreen pictures for your manufacturer to include on the circuit board's lower and upper parts. Besides, there will be templates containing different drill holes, their position, and use.

Why to use Gerber files in PCB layout?

Initially developed by a company with the name of Gerber, Gerber format currently refers to a widely accepted standard PCB industry software sticks to, capable of describing circumstances of board images such as conductor layers, soldermask layers, legend layers.

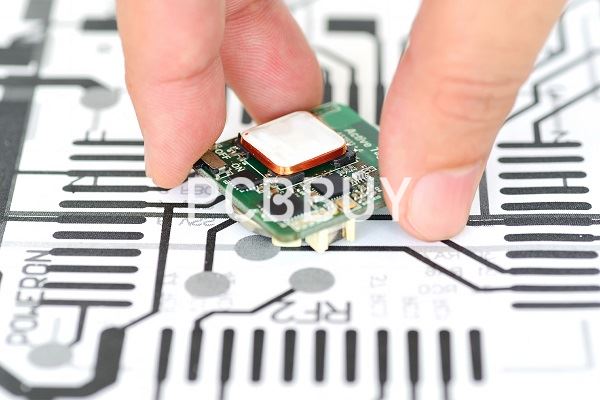

Printed circuit boards are designed in a specialized EDA (Electronic Design Automation) or a CAD (Computer-Aided Design) system that further generate board manufacturing data based on which circuit board fabrications are commenced. PCB manufacturers won't fully understand all details of a PCB design file unless Gerber format file is contained in it as reference and guidelines. Gerber format file is applied to describe design requirement of each image of a circuit board and it can be applied for both bare board fabrication and PCB assembly.

When it comes to bare board fabrication, Gerber format is called for by both standard photoplotters and other manufacturing equipment desiring image data like legend printers, direct imagers or AOI (Automated/Automatic Optical Inspection) equipment etc. put it simply, Gerber format files have to be depended from beginning to the end of PCB fabrication process.

How to generate Gerber files in PCB layout?

PCB design engineers should never be too lazy to generate their own Gerber files for the following two reasons.

You are hardly able to make sure the PCB design software you're using is the same as that is being used by your PCB manufacturer. If your PCB manufacturer uses different PCB design software, you have to generate Gerber files by yourself, further conversation and confirmation will definitely cause more time and delay the production process accordingly.

Altium Designer

With your .pcb file opened with Altium Designer software, click File>>Fabrication Outputs>>Gerber Files sequently. Then, Gerber Setup dialogue window will come out, in which five items are available for engineers to set corresponding parameters in their Gerber files: General, Layers, Drilling Drawing, Apertures and Advanced.

Industry Category