How to Identify PCB Fault Detection Using Image Processing?

By:PCBBUY 04/27/2022 11:18

If you have resided in a warm-weather climate (Florida) for the majority of your life, then you can relate to a new recruit (Me) serving in the Navy in Great Lakes, Illinois experiencing culture shock during his first Chicago, winter. I can attest that temperature is a disruptive environmental factor.

The main objective of Etching process is to remove the exposed unwanted copper other than the required circuit pattern. In order to minimize scrap caused by the wrongly etched PCB panel, inspection has to be done in early stage. If you are looking for more information about PCB fault detection, please check and read the content below.

What kind of PCB fault detection need inspection?

With all of the parts, connections, and other critical aspects of a circuit board that must be examined, some complicated PCBs can have up to three or four thousand opportunities for errors. Locating a single problem out of so many possibilities is simply too many for manual inspection methods to reliably find, especially when you consider the volume of boards. Here, automated optical inspection systems detect anomalous conditions and flag those areas for closer scrutiny by human inspectors.

Before we delve into how automated inspection works, let’s first take a moment to look at all the different areas of a circuit board that require examination. Although our focus is chiefly on the assembly side of PCB manufacturing, automated optical inspection systems are also used by fabricators to search for the following:

Metal to metal shorts

Metal to metal spacing

Broken or cut metal

Improper widths of metal

Excessive metal on a net

Drilled holes breaking out of the metal

For circuit board assembly, AOI equipment will verify the following conditions:

Solder paste application

Good solder joints

Targeting fiducial locations

Component alignment

Component values

Polarity indicators

PCB markings such as labels

As you can see, many items can be automatically inspected using AOI equipment. Next, we’ll see how this is accomplished.

How PCB Fault Detection Using Image Processing Inspects a Circuit Board

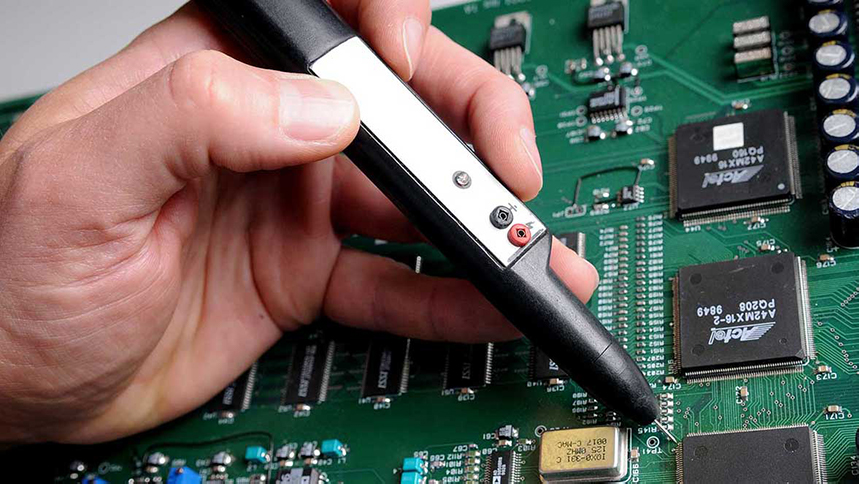

Depending on what portion of the circuit board is being inspected, different AOI systems are used. Solder paste inspection equipment, for instance, will use laser scanners with micron resolution to determine the amount of solder on a pad.

The automated optical inspection systems used for PCB assembly verification rely on LED illumination and high-resolution cameras to capture circuit board images. Using a known good, or “golden” first article board, the AOI system will capture images of its part markings and solder joints. These images are clear enough to record polarity indicators, color codes, and other markings and compare subsequent circuit boards. Once recorded, the system can detect incorrectly aligned components, open solder joints, and solder bridges on new boards using the standard.

How to build application of PCB fault detection?

PCBs are prone to a variety of defects that impede proper manufacturing, costing companies money. Defects such as shorts, spurs, mousebites, and pinholes cause issues like current leakage and open circuits, quickly degrading performance or rendering PCBs useless. PCB manufacturers must strive to ship defect-free units to remain competitive and ensure customer satisfaction.

Failure analysts are employed to ensure defects are kept to a minimum. But inspecting and diagnosing defects manually is challenging. There are multiple defects to detect, an extremely low tolerance for errors, and significant expertise required to reliably recognize and handle flawed units. Considering the time to train new analysts, and the cognitive load required to ensure reliability, an automated solution to detecting and classifying defects in PCBs is in demand.

In this article we will build a full PCB Defect Classifier that automates the task of detecting and classifying defects in printed circuit boards. I always encourage AI practitioners to build full products rather than throwing models over the fence to developers and other engineers. Your machine learning must exist in concert with a full application; thus only through its survival inside a holistic product can you be certain you’re building for users, not engineers.

How PCB fault detection using image processing inspects a circuit board?

Depending on what portion of the circuit board is being inspected, different AOI systems are used. Solder paste inspection equipment, for instance, will use laser scanners with micron resolution to determine the amount of solder on a pad.

The automated optical inspection systems used for PCB assembly verification rely on LED illumination and high-resolution cameras to capture circuit board images. Using a known good, or “golden” first article board, the AOI system will capture images of its part markings and solder joints. These images are clear enough to record polarity indicators, color codes, and other markings and compare subsequent circuit boards. Once recorded, the system can detect incorrectly aligned components, open solder joints, and solder bridges on new boards using the standard.

The image recognition can also be de-tuned to reduce false detections or increase its sensitivity for extra critical areas of the board. AOI systems can also be programmed to accept alternate part numbers to keep acceptable replacement parts from being flagged as errors. This ability to fine-tune the AOI system allows operators to configure it to its most optimum level for fault detection. Now let’s take a look at the actual inspection process used during manufacturing.

Industry Category