How to Make Arduino PCB for Beginners within 5 Effective Methods?

By:PCBBUY 12/15/2021 09:31

Arduino is an open-source software and hardware firm which allows you to construct and design electronics projects. You can effortlessly use the Arduino circuit board to manufacture interactive and digital devices with control systems and sensors.

Are you a beginner of PCB industry? Are you going to learn the detailed knowledge of Arduino PCB? If you are curious about the Arduino PCB, please check and read the content below for more information.

1. Why we process Arduino PCB?

Arduino circuit boards are built primarily for prototyping, while an actual board is a standard production board. The only possible reason for using an Arduino in the development is that you can't produce a real board. There is no need to remove the connections from the Arduino circuit boards and re-solder the new wires. Depending on the components you intend to incorporate, you can even find Arduino circuit boards that already provide you with everything.

For production purposes, it only takes a few hours to build an actual circuit board. You have power over the components used based on how many of them you wish to include. Furthermore, you can Additional debugging/test/expansion pins to use them afterward. However, the Arduino circuit boards do allow you to build projects all on your own. In the other case, you need to contact a PCB manufacturer.

2. What are the advantages of Arduino PCB?

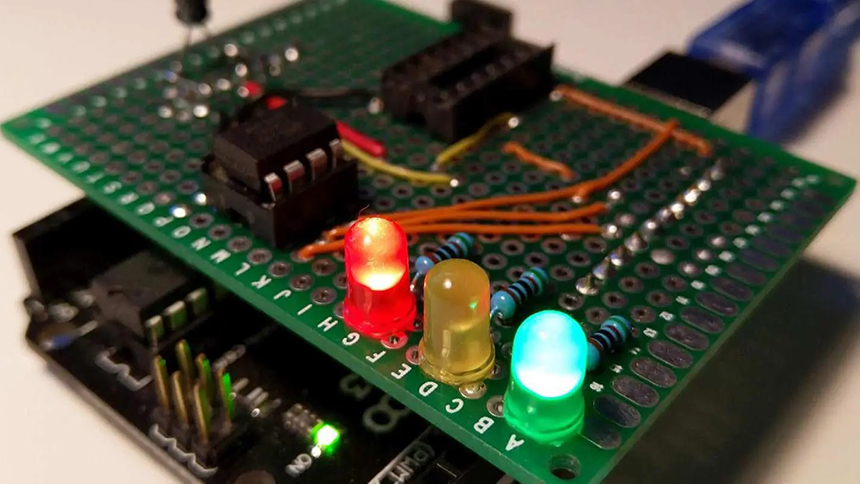

Arduino circuit boards are more durable and dependable for making simple to complex projects. The blue-colored board already comes with soldered input and output ports. Arduino PCB helps you design and construct most electronic projects. This circuit board has its own advantages.

Reliability: Arduino circuit boards are more reliable for designing both simple and complex electronic projects. This board already features soldered output and input ports. When using it you don’t have to worry about the solder wearing off.

Cost-effective: Arduino boards are cost-effective options. They are relatively low-priced compared to other microcontrollers. The pre-assembled Arduino modules go for less than $50. You can assemble the cheapest version of the Arduino module by hand.

Ready to use: Arduino PCB board is simple and ready to use. This circuit board is a complete package that contains an oscillator, a serial communication interface, a burner, LED, micro-controller, and 5V regulator. With these components, you don’t need to think about the connection for programming. All you just do is plug it into your computer’s USB port, voila!

User-friendly: This is one of the benefits that distinguish this board from other circuit boards. The Arduino software is user-friendly for beginners and experts. This board features a clear programming environment that allows students to get familiar with how the software works. You don’t need to acquire much knowledge to start.

3. How to process Arduino PCB?

There are three massive reasons why you might wish to consider using Arduino for your product prototype and to create a PCB. The first reason is that Arduinos are designed to be very easy to use. Ease of use is vitally important for your entire product development lifecycle, regardless of how large or small your project is in scope. Ease of use will help to keep your costs down, and to minimize technical problems.

Another important reason why Arduino is ideal for turning into PCBs is that Arduino is a fully open-sourced architecture, so you never have to worry about obstructed rights, rules, code, or hardware. Finally, Arduino boards are very cheap, so you don’t have to stress out when experimenting with your initial prototypes or rolling out the assembly of your product in its final form.

4. What are the considerations of prototyping Arduino PCB?

After you’re satisfied with the architecture of your prototype, the next natural step is to consider the actual PCB (printed circuit board). As you may be aware, the open-source nature of Arduino grants you easy access to the schematic design for your board and any Arduino shields. However, there’s a very good chance that you’ll need to adjust your PCB per your own prototype’s unique design, function, and specifications.

When you’re designing your PCB, always ask yourself what unique specifications can help to make or break an ideal design? How are your end-users going to use the device, and what nuances might affect performance? Pay very close attention to which, if any, Arduino shields require special accommodations, such as location or position.

For example, if your prototype uses any Wi-Fi or GPS antenna, then make sure that you place the shields so your device can get the ideal connectivity! If your prototype requires the use of an LCD, then be sure that your LCD is in the ideal location so your end-user can get easy access! If your prototype measures the temperature or requires any input from the end-user, plan for this so that your PCB design is optimal and practical.

5. How to choose proper Arduino PCB?

Since there are several types of Arduino boards available it is important to know the appropriate one that suits your application requirement. The best way to choose this board is by distinguishing the trade names on the original boards.

The Arduino IDE can be used for the programming of circuit boards. The IDE of Arduino is written in Java. You can get inexpensive Arduino boards via online websites or at electronic stores. Arduino boards are available in different types and as such, they have different features, specifications, and benefits.

Choosing the right Arduino boards entails that you consider the application you are using them for. The choice of the Arduino board depends on the budget and requirements of the electronics project.

Industry Category