How to Make LED PCB Board Trough 5 Effective Tips?

By:PCBBUY 10/14/2021 09:07

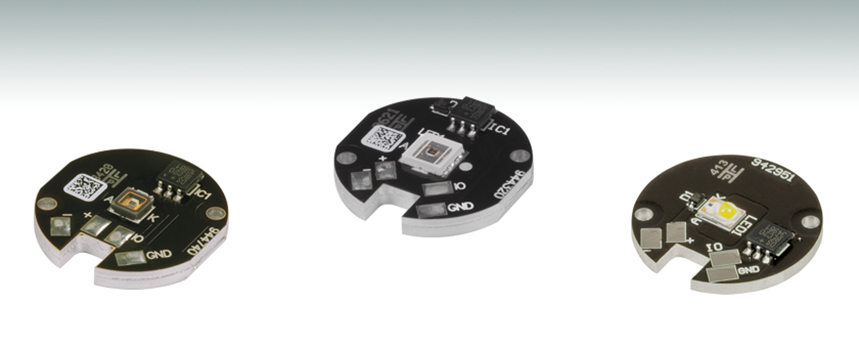

LED is an acronym for light emitting diode, which is semiconductor diodes. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Needless to say, LED PCB is the core of LED lighting, and an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods.

In this passage, follow us to learn more information about the methods of LED PCB. Please check and read the content below for professional knowledge.

1. What are the types of LED PCB?

There are different types of LED PCBs. LED PCB Board types to vary on the basis of manufacturing specifications, type of material and usage. Here are the most popular types of LED PCBs including:

Flexible LED PCB

The name is quite obvious. It is comprised of materials that can twist in different directions, and flex. It contains layers including multilayer, double and single formats. It is a little bit costly to print a circuit on the flexible material. The flexible LED PCB Board has more advantages as compared to a rigid LED Printed Circuit Board.

Rigid LED PCB

As the name suggests, it is stiff and totally opposite to the flexible one. The solid material is used for its manufacturing. You can find it on the computer. It is also available in different layers.

Multi-Layer LED PCB

This type of LED PCB Board contains more than two layers. Copper plated holes most often interconnect all the layers. It contains 4 to 50 conductive material layers. A special type of glue connects multiple layers and a special type of insulator is used in between different layers. The insulator protects them from an excessive amount of heat.

2. How to balance the current for LED PCB?

LED light, the soul of lighting globally, enjoy merits such as high illumination, long lifetime, stability, and low energy consumption. That is why the technology has wiped out some other contemporary lighting methods, such as halogen and fluorescent tubings.

But even with the merits, the technology came with one disadvantage that undermines its efficiency a great deal—a custom led circuit board tends to generate high heat energy. Thus, the system cannot cool efficiently through traditional means.

The custom LED PCB assembly uses metal core PCBs due to their high efficiency when it comes to problems related to heat dissipation. Some other companies use aluminum PCB. The metals have thermally conductive dielectric materials that conduct heat with unmanageably higher efficiency while at the same time dissipating heat.

3. What are the capabilities of LED PCB?

As an experienced LED PCB Manufacturer at Technotronix, we bring complex designs to life. Our extensive capabilities in LED printed circuit boards include:

· Rigid, flexible as well as rigid flexible boards for LED.

· Metal Core LED circuit boards

· Embedded LED PCB

· SMD LED circuit boards

· A wide range of finishes - SMOBC/HASL, electrolytic gold, electroless gold, electroless silver, immersion gold, immersion tin, and OSP

· Option of base plate - Copper or Aluminum

· Choice of PCB Core - FR-4, Epoxies and aluminum laminated with copper

· Dielectric thickness: .003"

· ROHS compliant/Lead free assemblies

· Automated Optical PCB Inspection, Electrical testing and sample inspections

4. How to select right material for LED PCB?

The PCB serves a number of purposes in LED-based circuit designs; most notably it provides the electrical connections between individual components and the electrical insulation of conductors from one another, but often the PCB also forms one of the very first elements of the thermal pathway between the LED component and the ambient air, whilst the PCB can also form a foundation onto which non-electronic components are also mounted I.e. lens and reflectors.

There are various PCB materials that can be used for LED applications: both FR4 and insulated metal substrate (IMS) are popular choices. Each material has its own relative merits, ranging from cost through to thermal performance.

5. What are the applications of LED PCB?

You may be wondering about the possible use cases of LED PCB. The applicable cases are many, but we will mention some of the popular ones.

Medical Industry

It will interest you to know that the medical industry is one of the major beneficiaries of the applications of LED PCB. Most of the medical equipment you know or see in the hospital are made from LED PCB. The reason for that is because LED PCBs tend to provide more light than traditional circuit boards would.

Telecommunications

Aside from being used in the medical sector, LED PCB can also be used in the telecommunications industry. There are two major roles played by these circuit boards in telecommunication devices.

First, LED PCBs (especially those manufactured with aluminium PCB) effectively transfer and dissipate heat from the board. Second and most important, LED PCB are used in the telecommunication sector because of the boards of the overall importance of the displays and indicators on the boards in telecommunication equipment.

ICT and Tech

If you are conversant with how the IT industry works, you will understand why LED PCB are mostly used instead of the other circuit boards. For instance, computers and Personal Computers (PCs) heat the most after some hours of use. That could cause damages to the internal components of the computers. However, if the PCs and computers were manufactured with LED PCB, the damages will be limited because of the effective dissipation of heat from the circuit board.

Automotive Industry

This time, we are looking at how LED PCB can be the last resort for automobile manufacturers that want to improve on the quality and effectiveness of their indicators and brake lights. LED PCB are mostly preferred during automobile production because of their increased efficiency and competitive pricing.

Industry Category