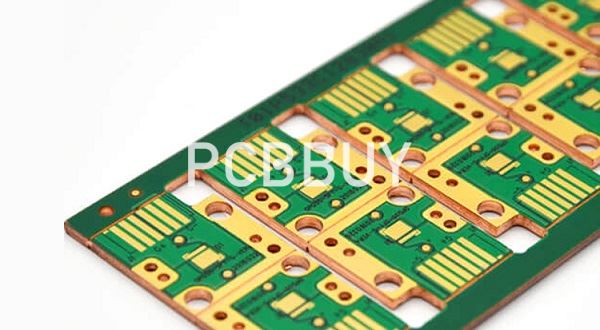

How to Make PCB Waterproof to Guarantee the Quality of PCB?

By:PCBBUY 12/17/2021 09:40

Lastly, water isn’t the only concern when it comes to PCB protection. The PCB may be exposed to extreme heat or chemicals when deployed. In such cases, acrylic is not a good choice as it does not tolerate high temperatures well.

Do you know the information of making PCB waterproof? Are you going to process the waterproof PCB? If you are searching for the professional knowledge of making PCB waterproof, please check and read the content in this passage below.

How to choose waterproof material for PCB?

This method is used for very special purposes, such as making PCBs for control systems of ships or submarines, etc. In this way, you can add some special material on the surface of the PCB board to make it waterproof, such as Parylene C or Parylene N, etc. In fact, Parylene C and N are the same material. They are both high-density polymers, which can be made into thin layers.

Generally, they are in liquid form when we apply them on the PCB boards. They will be solidified after a certain time, and become waterproof. The thickness of Parylene C is around 2 mils (0.05mm), which is much smaller than that of traditional varnish (such as epoxy resin). If you need to make your PCB board waterproof, you can choose Parylene C or Parylene N as your material.

How to process waterproof coating on PCB?

Making a plastic housing waterproof generally requires a lot of skill and experience. Even then quite a few iterations of testing and mold modifications will be needed to get it right. It generally involves adding a soft material such as TPR between the mating surfaces. The cheapest way to do this is to friction-fit or glue a TPR o-ring in place, but this is a laborious and error-prone process.

Better is to combine the soft and hard plastic into a single part, using overmolding. For high quantity products, such as toothbrushes 2K molding is used technology, where a mold…. molds and injection machines. The molds and injection machines needed for this technology tends to be roughly 3 times as expensive as for a single plastic part.

For order quantities under say 50K it is much more advantageous to use the “sneaker method” where an ABS part is taken out of one mold and walked over to the next machine where the TPR is injected over it.

Why to use waterproof coating on PCB?

So protecting the circuit is important, especially so when it is exposed to an aggressive environment (Solvents, high temperature, humidity/water spills, etc). Waterproof conformal coating can help with all of this.

In fields such as automotive, aeronautics, or medical, it is essential to provide PCBs with a suitable conformal coating in order to increase reliability.

When applying a conformal coating, there are four factors to be checked and optimized:

· The conformal coating material

· The conformal coating application method

· The conformal coating curing and drying method

· The conformal coating inspection method

Your best pick for each of these factors will depend on the production volume and lead times, the fixtures available, the environment, the complexity of the PCB, etc.

How to process the waterproof application on PCB?

Dispensing

This application process is the most commonly used to paint PCB boards. In this process, paints are stored in a hopper and then pumped into a gun. The paint will be sprayed onto the PCB board with the help of a spray gun.

Manual Spray

This process is similar to dispensing, but manual spray can be used when you do not have a special painting machine or there are many different PCB boards for painting, which cannot be painted by dispensing. It is better to use manual spray rather than dispense method if you can because manual spray allows you to paint with high precision and makes the surface of PCB board smooth.

Dipping Process

In this process, the PCB board will be dipped into the paint tank to be coated. It is a common process in the industry. However, it is really not recommended for you to use the dipping process when you are making PCB boards and electronics, because PCB boards should have some thickness. If you dip your PCB boards into the clear coat, most of the clear coat will stick on the surface of the PCB board and some will remain in the paint tank. This will result in uneven PCB coating of clear coat on the PCB board.

Industry Category