How to Make PCB with Laser during Custom PCB Manufacturing Process?

By:PCBBUY 12/21/2021 09:40

PCB laser is used for marking circuit boards, an important step in PCB manufacturing. Since electronics manufacturing is becoming complex it is important to mark boards to determine major components and make sure that parts are placed in correct positions so that they can be well connected.

Do you know the methods of making PCB with laser? If you are looking for the information of making PCB with laser, please check and read the content below

What are the types of lasers in PCB?

Identifying marks have become an important aspect in PCBs manufacturing. Traditionally, identifying marks are done alphanumerically, but there are restrictions due to the space available on the PCB surface. That is why lasers are used in marking PCBs since they can offer accurate marking. Fiber laser PCB can help to include identifying codes to any PCB surface; they can use QR codes or bar codes to cram information into a smaller space.

Lasers are also very fast when it comes to marking PCBs. They can etch codes in a few seconds while preventing the material around the area of application from any damage or distortion. Laser marking also provides information in the manufacturing of integrated circuits. In this application, precision, efficiency, and precision are very important.

It is also important to know that using lasers to mark printed-board-circuits correspond with the marking of components by using the same procedure. This makes it easy to trace and replace parts while making sure that sensitive and fragile parts aren’t placed under undue pressure.

What are the advantages of laser drilling of PCB?

The advantages of using lasers are listed below:

· Non-contact process: Laser drilling is a non-contact process and hence the damage induced on the material by drilling vibration is eliminated.

· Precise control: We can control the beam intensity, heat output, and duration of the laser beam. This helps to create different hole shapes and offers high accuracy.

· High aspect ratio: One of the most important parameters of a drilled hole on a circuit board is the aspect ratio. It is the ratio between the drilled depth and the diameter of the hole. Since lasers can create holes with very small diameters, they provide a high aspect ratio. A typical microvia has an aspect ratio of 0.75:1.

· Multi-tasking: Laser machines used for drilling can also be used for other manufacturing processes like welding, cutting, etc.

What are the different lasers for PCB drilling?

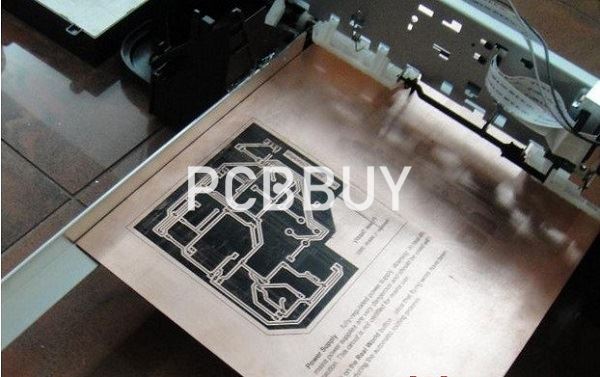

There are different types of laser machines available that can be used for a variety of purposes. These purposes can be hole creation, etching, depaneling, etc. Out of these, only those machines which can accurately create small holes on the type of materials used for circuit boards should be used as PCB drilling machines.

What is a PCB drilling machine?

A PCB drilling machine drills holes with high precision and accuracy based on the provided data. This data includes the exact position, number, and other parameters of the holes to be drilled.

Types of laser drilling machines

Different types of machines for laser processing are available depending on their operating principles. The most commonly used machines for drilling microvias are CO2 and Nd:YAG lasers. Excimer lasers are also available and are used in the etching of polymers. They are not suitable for the removal of metals.

CO2 lasers

Carbon dioxide lasers use gas as the lasing medium and emit light in the IR spectrum with around 10.6μm wavelength. These lasers create holes with 50-70μm diameter. CO2 lasers are one of the high-power lasers available today and are suitable for the drilling of polymers. These lasers have high reflectivity from metal surfaces. They are mostly used in areas where the speed of drilling is of primary importance. For around 80% of microvia drilling, CO2 lasers are used.

Nd:YAG lasers

The lasing medium in the Nd:YAG lasers is solid. Their fundamental emission is in the IR spectrum with a 1064nm wavelength. With non-linear crystals, they emit light in the visible spectrum (532nm) and in the UV spectrum (355 or 266nm). The Nd:YAG lasers can emit up to 100,000 pulses per second. The diameter of the focussed beams of these lasers is 12 to 25μm. For holes with higher diameters, they use the trepanning method.

The Nd:YAG lasers are the most versatile and can be used to drill on different types of materials such as polymers, glass, and metals, etc.

How to Select Laser Routing for PCB Depaneling?

Laser routing is one of the popular approaches to depaneling. This procedure ensures that there is no physical contact with the board. Many producers consider laser routing to be ideal for sensitive and small PCBs used in the most recent wearable technologies.

UV (355 nm wavelength) and CO2 (10.6µm wavelength) are the two lasers for PCB depaneling. The relative importance of cycle time and the neatness of the cut edge are the most important factors to consider when determining the type of laser to use.

Choosing the Right Laser Source

It is important you determine the appropriate laser source for your depaneling needs. CO2 and UV lasers have their disadvantages and advantages.

UV lasers

Lasers that involve UV use “cold” cutting technology. UV lasers make it easy to control the thermal charring of the edge. Therefore, a UV laser is a better option if reducing char is more vital than speed.

Industry Category