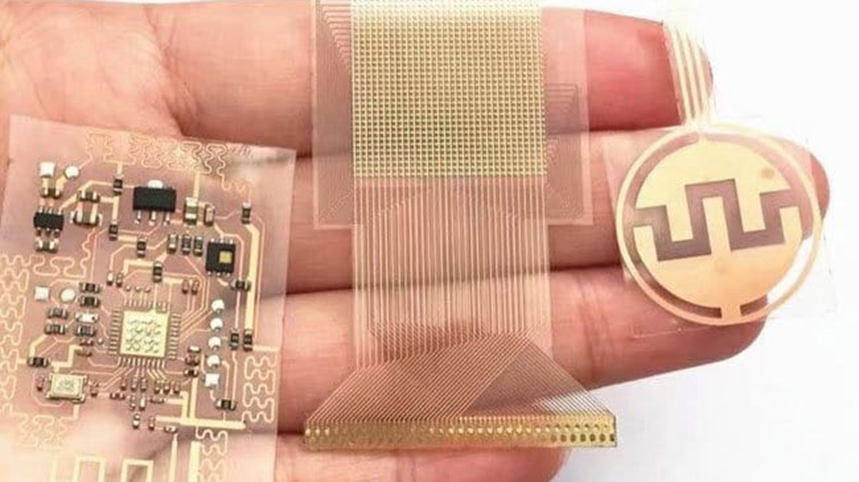

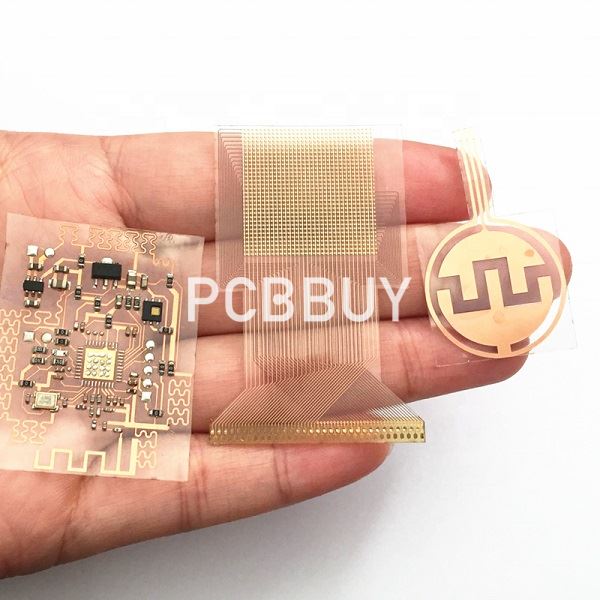

How to Make Transparent PCB during the Manufacturing Process?

By:PCBBUY 12/04/2021 09:46

There are two main substrates for transparent PCBs. It’s either ceramic or glass. Ceramic transparent PCB substrates have high thermal conductivity compared to glass. However, it has a slightly lower transmissivity. Its transmissivity is about 75 to 85% compared to 99.5 to 99.99% for glass.

If you are going to know the process of transparent PCB, we are going to search for more information about transparent PCB and the methods to make them, please check and read the content in this passage below.

What is the substrate of transparent PCB?

Glass PCB usually used in LCB, LED. We can make it with the raw material of glass. In the glass PCB, we have to transfer the circuit onto the copper board using a UV curable mask. UV curable masks provide perfect results even with narrower track widths. This is the technique utilized even in bulk PCB manufacturing. When exposed to UV light, a thin coating of UV curable etches resist hardens. This resistance is applied to the copper board and exposed to a UV light source through an opaque film containing an image of the circuit. The circuit design is cured on the resist film in this manner. The uncured film may be removed using a developer, and the circuit is ready to be etched. Don’t be misled by the term developer; it’s just a low basic solution, similar to baking soda that can remove uncured UV resistance.

UV resist films are classified into two types: positive and negative. When the developer is applied, the exposed portions of the photoresist remain undissolved while the remaining parts dissolve. The opposite of negative is positive. In this Intractable, I’m going to utilize a negative one.

There is the material that we have to use to make a glass printed circuit board:

· Piece of glass, as needed

· UV photo resistance

· Baking soda

· The foil made of copper

· Chloride of iron

· Printout from OHP

· Glue

What are the considerations of transparent PCB?

But let’s take a look at the common glass materials for a brief knowledge of the transparent glass PCB.

· Tempered glass is the most common glass material you will see. It is a reprocessed and pre-stressed glass that ensures added durability. Also, it has higher impact and shock absorbing strength for extreme uses.

· Next on our list is the quartz glass. Although it has a less impact-absorbing facility, its wider use in the electrical and electronic industry makes it the most sought-after glasses. You will see the quartz glass in semiconductors, optical devices, medical and military industry, and what not! It has improved temperature resistance, chemical stability, and UV transmission.

· Sapphire glass is by far the strongest and hardest glass on the planet. Thanks to its high thermal and dielectric properties, it is used in many complicated and high-end devices. You will see its applications even in space and satellite technologies and devices.

Now that we know about glass and its materials let’s focus on the transparent glass PCB. These printed circuit boards are made of transparent glass with a 360-degree illumination facility. It means light an pass through the surface, and you will see illumination from all sides.

What are the advantages of transparent PCB?

Already, glass material is advanced. Whenever it is utilized in making transparent printed circuit boards, it will surely add some value to constructions of circuit boards. Transparent PCBs are not exempted

Light can pass through transparent PCBs. This makes the transparent PCB versatile and better. Also, transparent glass pcbs are usually flat. This means it will have great symmetrical functionality and less flaws. This increases the efficiency and durability of these devices.

These transparent pcbs also have high heat resistance and temperature. Glass has the ability to withstand a temperature of about 1000 degrees. In addition, you can produce it easily in large quantities for PCBs and semiconductors.

Glass transparent PCBs can be manufactured easily. This is because glass can be gotten from recycled items like sand and ash. This makes glass transparent pcbs lower priced compared to ceramic pcbs. Therefore, with glass transparent pcbs, the cost of production of all your devices will be lowered.

Industry Category