How to Manufacture PCB:5 Tips of PCB Thickness Tolerance

By:PCBBUY 01/12/2022 09:17

Many contract manufacturers may say that the standard PCB thickness is 1.57 mm, or approximately 0.062 in. This is true to an extent. Apparently, this was the size that bakelite sheets were manufactured in during the earlier days of board fabrication and the size has stuck. Therefore, we can refer to this as the historical standard PCB thickness. Today, boards are made to be larger and smaller than this standard, but the standard probably remains the most common thickness for designs.

In this passage, we will show you everything about the PCB thickness tolerance, and if you are looking for professional knowledge about PCB thickness tolerance, please check and read the content for more information.

What are the tips of PCB thickness tolerance?

1. What is the standard of PCB thickness?

The typical PCB thickness is 0.063inches or 1.57mm; it is a standardized level defined from the past. That is because, during the plywood industry, 0.063" was the thickness of the plywood sheets used as substrates for electronic devices, which included PCBs.

When multiple layer PCBs started developing, the thickness of the connectors between the boards had to match. Therefore, the level of consistency became a significant variable, and there was a requirement for a standard deck of the copper used as layers on the plate edges. In turn, 0.063" became the Standard PCB Thickness.

The width of the board is reliant on the insulating layer and the content of its material. Early in the development of PCBs, the layers, top, and bottom were made of Bakelite, and the resultant thickness was 0.0065".

2. What are the options of PCB thickness?

The number of layers your PCB determines the overall thickness of your PCB. Some applications require a thicker PCB while some require a thinner type. SO the thickness has very varying standards. The typical range of thickness for the core and prepreg combined is between 0.008 -0.240 inches.

3. What are the factors affect PCB thickness?

Size, Weight and Flexibility

Thinner boards are lighter and more flexible than their thicker counterparts but will break more easily due to brittleness. While flex PCBs must be thin to achieve their flexibility, applications that do not require flexibility may benefit from a slightly thicker board for the sake of structural integrity.

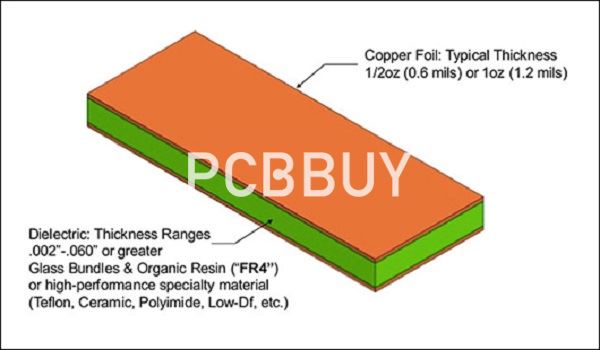

Copper Thickness

Copper thickness plays a role in the overall thickness of the PCB. The thickness of the copper layer used usually depends on the current that needs to pass through the PCB.

Board Materials

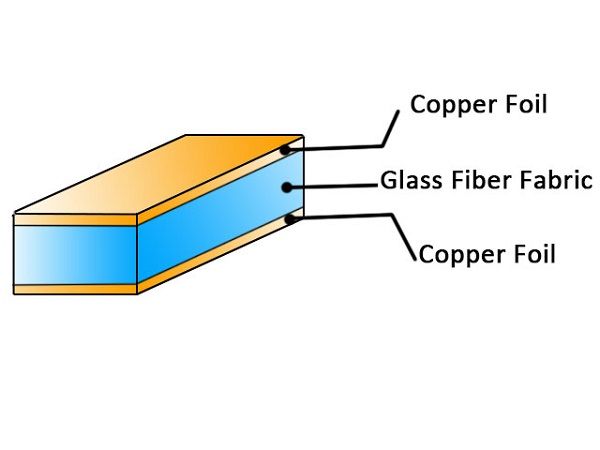

The operation and lifetime of a PCB depend on the choice of materials, but these choices also impact board thickness. Typical board fabrication consists of the substrate, laminate, solder mask and silkscreen. Of these, the laminate and substrate are the most important materials for consideration, as they provide the structure of the board and greatly impact overall thickness.

The Number of PCB Layers

The number of PCB layers will, understandably, influence the thickness of the board. While 2-6 layer PCBs thickness may fall within the standard threshold of PCB thickness, 8-layer and up PCBs thickness may not.

4. How to custom PCB thickness?

Sheets or panels used for manufacturing PCBs are easily available in the market. There are various customization options that offer designs and thicknesses as per your specifications and needs. You can pick the thickness range from 0.2mm to 6.3mm in millimeter increments of a hundredth. Read further to find out factors that must be supervised while opting for a customised PCB board thickness.

· Turnaround time: Generally, the expected turnaround time to receive a customized PCB layer thickness is more due to the uncommon thickness specifications. This will impact your delivery schedule and development timing.

· CM’s equipment capabilities: If you do not want to compromise in your design and model, be careful while choosing your CM. If your CM has limited options of equipment to manufacture and design the typical PCB thickness you are looking for, you will have to compromise and modify your PCB layout.

· Additional costs: Customization costs are generally higher due to the additional details and expectations. The use of specific material, design, and adhering to a detailed set of instructions amounts to additional manufacturing costs than usual prices.

5. How to determine PCB thickness?

Choosing the right copper thickness plays an integral role in circuit board assembly. When considering the thickness of your PCB copper, there are two things to keep in mind. The first element to consider is the barrel’s current capacity for heat rise. The second is mechanical strength, which is determined by the thickness of the copper, as well as the size of your plated-through hole (PTH) and the presence or absence of support vias.

There are a number of materials that circuit board assembly services can choose from when designing a PCB. Such options include the standard FR4, which operates at a temperature of 130 degrees celsius. High-temperature polyimide is another option — this material can stand up to 250 degrees celsius.

Industry Category