How to Measure PCB Trace Impedance in Layout with 3 Tips?

By:PCBBUY 09/16/2022 16:10

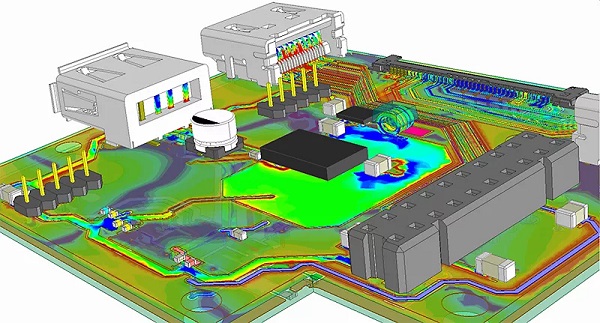

Every trace has a small, nearly indistinguishable series inductance distributed along the trace with an inverse relationship to the cross-section of the trace. As rise times increase, the resulting impedance becomes more noticeable. By the same token, each trace has capacitance distributed along the trace and the return path signal, which is a function of the width of the trace and the dielectric of the material between the signal return path and the trace. Once again, if rise times increase enough, the impedance generated as the current tries to flow through this capacitance can be significant.

If you are curious about PCB trace impedance, you can check and read the content below for more information and professional knowledge.

How to measure PCB trace impedance?

To manufacture controlled impedance printed circuit boards, one must be able to measure impedance. The best way to calculate trace impedance is by using a trace impedance calculator. You can find trace impedance calculators online or in your CAD software. There are several parameters to consider when determining impedance, including:

· Trace width

· Trace thickness

· Laminate thickness

· Dielectric thickness

· Copper weight

Once you have calculated all relevant parameters, you can adjust the all of the above (typically the trace width) to arrive at the impedance you are looking for. Once you think you are at an acceptable impedance, you can test the board’s effectiveness using test coupons manufactured on the same panel at the same time, so you can get a good impedance rating without the challenges of accessing the traces on the actual board. The test coupon traces should be identical to the board traces in order to get an accurate test.

Typically, the manufacturer will build test coupons on either end of the production panel so that by testing both coupons, you get a very reliable impedance reading without damaging the board. Testers measure impedance with a Time Domain Reflectometer (TDR) or a network analyzer.

Impedance can be measured using a network analyzer, a laboratory Time Domain Reflectometer (TDR) or a controlled impedance test system that employs TDR techniques. An engineer with practice using controlled impedance test systems will run the impedance test to ensure high-quality results.

What is the work principle of PCB trace impedance?

Every trace has a small, nearly indistinguishable series inductance distributed along the trace with an inverse relationship to the cross-section of the trace. As rise times increase, the resulting impedance becomes more noticeable. By the same token, each trace has capacitance distributed along the trace and the return path signal, which is a function of the width of the trace and the dielectric of the material between the signal return path and the trace. Once again, if rise times increase enough, the impedance generated as the current tries to flow through this capacitance can be significant.

Your drivers read all traces as distributed LC circuits and your trace AC impedance comes from this distributed LC circuit. This is considered uncontrolled impedance. We make no effort to design the trace environment to account for this impedance, allowing the inductance and capacitance to vary as it will along the trace. Since the resultant impedance usually has no effect on operations, there is no need to waste time or money designing ways to control it.

How to control impedance of PCB?

Deal with signal integrity issues of PCB

Recently, the globe has seen a surge in the switching speeds of most electronic devices. Now more than ever, devices have become complicated and somewhat faster than before.

For instance, matters to do with Signal Integrity (SI) are far more recurrent as the device's operational speeds also increase. In other words, devices need to be in an excellent position to deal with any Signal Integrity issues. Apt examples of integrity issues on a printed circuit board include the following:

·Signal loss

·Ringing

·Power supply noise

·Ground bounce

·Crosstalk

·Distortion

By following the right design practices, designers can avoid potential SI issues. In this case, controlled impedance can help them in mitigating or averting signal integrity issues.

Industry Category