How to Meet the Requirements of PCB Layout Preparation?

By:PCBBUY 02/23/2024 14:51

When starting a new printed circuit board design, it’s sometimes easy to forget about the important design rules that will govern your project. There are some simple clearances that, if determined early in the design, will eliminate a lot of component shifting and re-routing later. So where can you get this information?

If you are curious about more information about PCB layout design guidelines, please check and read the all the content below in this passage.

How to Meet the Requirements of PCB Layout Preparation?

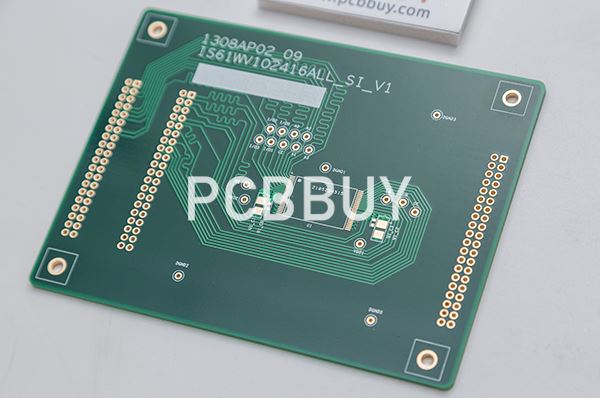

There’s a huge demand in the PCBs market, but not just any boards but quality boards made under the right procedures. PCBs are manufactured once a layout is prepared to attract a huge market. Therefore, designers and manufacturers are under pressure to manufacture boards that promise to bring about desired functionality regularly.

Plenty of PCB manufacturers lately, employ effective tools such as DFM software and PCB design tools to create the best layout plans. Such tools are effective as they bring about the best solutions for creating the best PCB layout. These and many other tools find use in a lot of PCB manufacturing firms since they are cost-effective and functional to PCB designers and manufacturers.

To meet the demands of producing functional PCBs that deliver as desired, many manufacturers are heavily concentrating on having layout prepared first. This includes defining the board's outline, placing the parts together, creating connections between the parts, and exporting them for fabrication. PCB layout preparation matters in producing high-functioning PCBs, a reason why plenty of PCB manufacturers lately consider this matter seriously.

What are PCB layout basics for engineers?

Whether you are moving at a high speed or you're designing a high speed printed circuit board, good design practices help ensure your design will work as intended and can be manufactured at volume. In this guide, we've compiled some of the essential PCB layout guidelines that apply to most modern circuit boards. Specialty designs may need to follow additional board layout guidelines, but the PCB layout guidelines shown here are a good place to start for most designs.

The guidelines shown here are focused in a few key areas that will help you with routing, manufacturability, basic signal integrity, and assembly:

· Defining design rules with the goal of ensuring fabrication and assembly yield

· Component placement, where the goal is to ensure solvability and ease of routing

· Grouping components by type to prevent the need to route all over the board

· Location of power and ground in the PCB stackup, including some points for mixed signal PCB layouts

· Obeying mechanical constraints, such as connector locations and enclosure limitations

What are routing guidelines for PCB layouts?

Next up, connecting your signal traces to match the nets in your schematic. PCB layout best practices recommend that you always place short, direct traces between components when possible, although this may not always be practical in larger boards. If your component placement forces horizontal trace routing on one side of the board, then always route traces vertically on the opposite side. This is one of many important 2 layer PCB design rules.

Printed circuit board design rules and PCB layout guidelines become more complex as the number of layers in your stackup increases. Your routing strategy will require alternating horizontal and vertical traces in alternating layers unless you separate each signal layer with a reference plane. In very complex boards for specialized applications, many of the commonly-touted PCB best practices may no longer apply, and you'll need to follow PCB design guidelines that are particular to your application.

What are the challenges for nice PCB?

Back when the devices on a board were simpler in nature, and only had one power and one ground connection, the noise tolerances were not as tight. You could easily control excessive noise with an extra capacitor. The switching speeds in those devices also didn’t create the same problems as the high speed devices of today do.

With the processor chips today on large ball-grid array (BGA) packages, the power requirements are much more intense. There is hundreds of power and ground pins in these devices, and each device may require multiple supply voltages with some of those voltages going down to less than one volt. These pins are also pulling many amps of current for the processor to do its job, and to provide “clean” power requires a huge network of capacitors.

What are certain guidelines for PCB layout?

There are many ideas and guidelines that can be drawn up for the design and layout of a PCB. The list below covers a number of them. Obviously there are more, and the PCB design guidelines list below should not be thought of as a complete list.

In order that the PCB design guidelines can be followed more easily, the guidelines are split into sections:

· Board constraint design guidelines - those covering the initial constraints on the board

· Overall layout design guidelines

· Guidelines associated with the planes or layers

· Track design guidelines

· Thermal issues

· Signal integrity and RF considerations

Industry Category