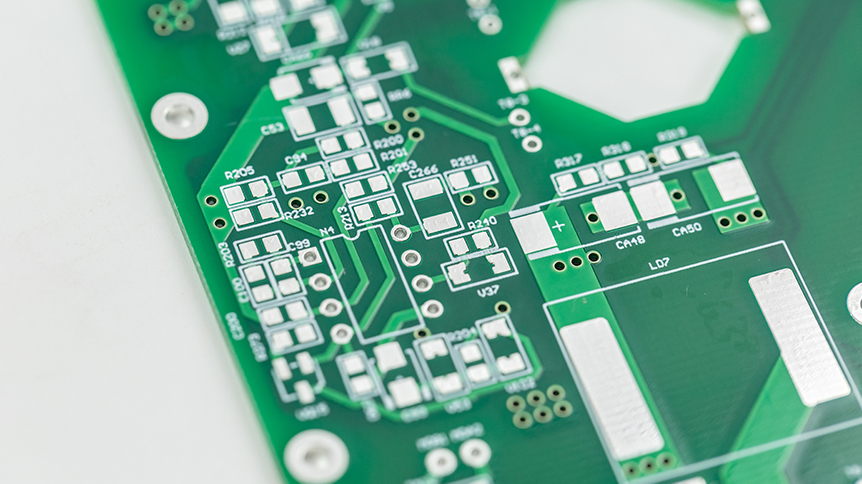

How to Mount a PCB in the Manufacturing Process by Step?

By:PCBBUY 08/03/2022 13:59

In this passage, we will provide you all the information about PCB mounting. If you are searching for the professional knowledge about PCB mounting, please check and read the content below in this passage.

What is the basic definition of PCB surface mount?

During the 1970s and 1980s the level of automation started to rise for PCB assembly for boards used in a variety of equipment. The use of traditional components with leads did not prove easy for PCB assembly. Resistors and capacitors needed to have their leads pre-formed so that they would fit through holes, and even integrated circuits needed to have their leads set to exactly the right pitch so that they could be placed through the holes easily.

This approach always proved difficult as leads often missed the holes as tolerances required to ensure they fitted exactly through the holes were very tight. As a result operator intervention was frequently required to resolve the issues of components not fitting properly and stopping the machines. This slowed down the PCB assembly process and considerably increased costs.

What are the main steps of PCB surface mount?

Here we divided the complete SMT soldering process into 10 steps:

· Printing

· Adhesive Dispense

· Component Placement

· Pre-Reflow Automated Optical Inspection (AOI)

· Reflow Soldering

· Post-Reflow Automated Optical Inspection (AOI)

· Conformal Coating

· Final Inspection and Functional Test

· Washing & Drying

· Packaging & Shipping

What are the advantages of PCB surface mount?

Several advantages come with SMT technology that you need to know. If you are thinking of using SMT technology in your PCB assembly, then you are bound to enjoy some of its benefits. Some of its merits include the following:

Reduced manufacturing costs

Surface Mount Technology comes with the promise of reduced manufacturing costs. SMT gives room for the creation of small PCB designs, hence reduced manufacturing costs. By using SMT, it’s possible to place components close to each other on the board. Therefore, manufacturers who use SMT technology enjoy the advantage of highly reduced manufacturing costs.

Improve work efficiency

SMT technology is also one of the best circuit assembly technologies as it improves work efficiency. It’s another reason why many PCB makers lately seem to prefer it. By relying on SMT, it’s possible to complete tasks in a single workday and within the shortest time possible. Unlike PTH technology, which may take some time, such is not the case for SMT. If you choose to assemble using Surface Mount Technology, work efficiency is a significant assurance that you’ll get.

The overall structure is more straightforward.

The overall structure of the boards you get to manufacture under SMT is simple. Unlike PTH assembled panels, the design of SMT made boards tends to be very simple. Surface Mount Technology assembled boards don’t demand too many technicalities such as drilling. In comparison to panels manufactured using other means, those made under SMT have more superficial structures.

Less error-prone

There’s nothing more demanding than having to do circuit board re-works due to errors. Another advantage of SMT technology is the fact that it’s less prone to errors. Unlike detailed PTH, Surface Mount Technology isn’t into too much detail as such. It’s possible to correct small mistakes for boards made under SMT. Manufacturers prefer this method as it makes them produce many boards without many errors.

How to choose PCB surface mount factory?

Choose the equipment

This is the first and most important thing to do when choosing a production facility. The factory must be located in an area with excellent communication systems. It is suggested to ask the factory owner why they chose that area.

Industry experience

Many factories will claim that they have been in the industry for a very long time, but this is not always true. If you are not careful, you may be cheated. Therefore, it is suggested that you should check the company’s records and find out how long they have been in business and whether or not they have a good reputation.

Delivery Ability

The next important thing to do when choosing a factory is checking their delivery ability. If a factory cannot deliver on time, it may render your project useless. Therefore, it is very important to check the factory’s delivery ability before making a purchase.

Industry Category