How to Prepare for PCB First Article Inspection?

By:PCBBUY 02/20/2024 16:06

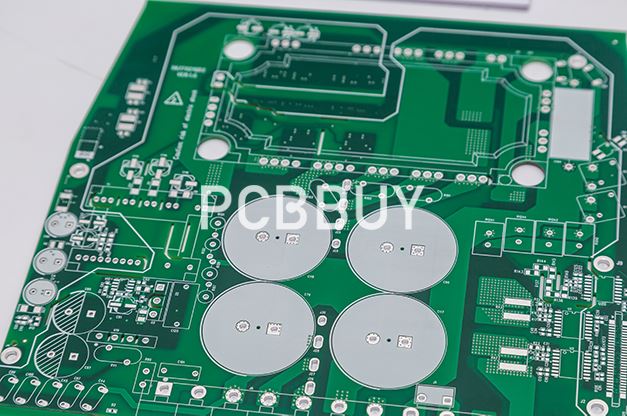

Inspecting your PCBs can uncover any defects that may have occurred during manufacturing or assembly. It can also help to reveal any design flaws that may exist. Checking PCBs after each phase of the process enables you to catch flaws before moving on to the next stage, which can save you from wasting further time and money on a defective product. It can also help you catch one-off defects that affect one or several PCBs. This process helps to ensure consistent quality among your boards and final products.

If you are searching for more information about PCB first article inspection, please check and read the content below for professional knowledge.

Why we need PCB first article inspection?

Basically, the qualification report qualifies the processes used by the manufacturer, and the first article inspection verifies that these processes output a PCB as expected during normal production builds. First article inspection does not apply to procured vendor parts. Typically, it is used when the manufacturer builds to the customer’s technical data package, and the supplier has never previously built the PCB.

The first article inspection is a standard process to ensure the design characteristics of a PCB forwarded to the manufacturer actually meet design intent when the PCB is actually produced. The customer may repeat the first article inspection entirely or in part if there are changes such as:

· Change in the source or location where the PCB is produced

· If the design change significantly affects the form, fit, or functioning of the PCB

· If there is a significant change in the processes related to manufacturing, assembly, inspection, or testing

· If any manufacturing equipment has undergone a significant change

· If a natural or man-made occurrence adversely affects the manufacturing processes

· The production process has been interrupted for a significant amount of time

· There is significant degradation is test yields

· Any change in manufacturing and/or test personnel on the product line

· Any change in a vendor supplied item with an age factor or revision factor

Therefore, it is necessary for our customers to clarify the purpose of the first article inspection so that PCB is able to mitigate the issues described above. Therefore, Rush PCB never treats first article inspection as just another check in the box, as many other suppliers do.

How to Prepare for PCB First Article Inspection?

Inspecting the first article units during the early stage ensures that engineers or technicians have the requisite understanding and consideration of the customer’s requirements and incorporated them into their manufacturing processes.

The pressure of reaching the market early tends to compress design schedules. This rushes the process of designing a new PCB assembly, testing it, and getting it ready for production, which often leads to errors. Customers, therefore, approach contract manufacturers like Rush PCB, due to their understanding and appreciation of an approval process such as the first article. A first article inspection process helps to identify potential issues in the early stages, so that the customer can take corrective actions.

Who conducts frist article inspection?

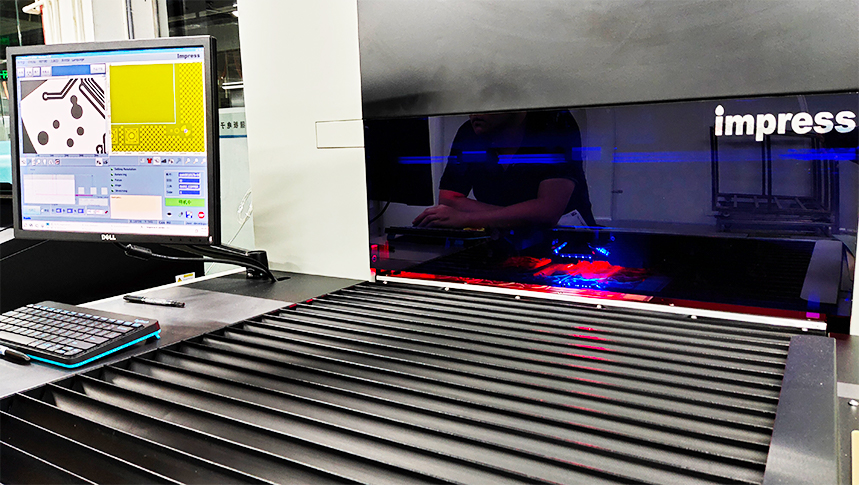

FAI is extremely important for the yield of high-volume PCB assembly manufacturing, but who will play the role of conducting the first article inspection? In Technology, there are 3 options. First preferred is conducted by you, the customer, in our SMT assembly facility in Shenzhen. Because we can start mass production run in a very short time to get approved in our time if no defects found in the first articles. Then improve our work efficiency under the situation of no stop production. Second preferred is conducted by both sides of you and us online.

We show you the HD photos and transfer the inspection and testing results as per inspection and testing procedures and QC standards. This process always takes a little longer time than the first, and requires a longer time of stop PCB assembly production, but the inspection and testing will be more carefully and considerably by both sides. Third preferred is conducted by ourselves according to the inspection and testing procedures in both sides. The disadvantage of the third option is that the PCB assembly manufacturer may ignore something inspection or testing if you forget to specified.

How to process PCB first article inspection?

The inspection of a first article circuit board build is a very thorough process. You CM should validate that 100% of all of your documented requirements have been met on this first build. To do that, the CM should be looking very closely at the following:

Measurable attributes: All of the measurable board attributes, such as dimensions, voltages, or resistance, should be measured and recorded. These values are then verified against the design specifications.

Manufacturing errors: Any problems that arise during the assembly process must be examined for changes and corrections. This can include component insertion issues to soldering problems.

Supplier validation: Parts and materials that are installed on the board should be verified to match their specifications. These include subassemblies, sheet metal, as well as cables and wiring harnesses.

Documentation clarity: Often in circuit board manufacturing, the source of confusion is from documented requirements that are unclear. The first article inspection will reveal any discrepancies between the documented requirements and what was expected.

Industry Category