How to Process Medical Device PCB Design with 5 Effective Tips?

By:PCBBUY 04/14/2022 09:42

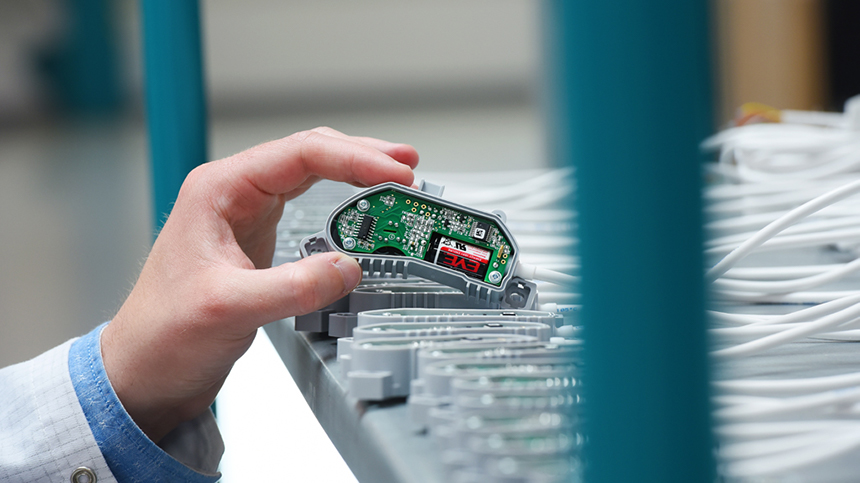

To ensure successful product launch, we offer design and engineering assistance to our medical device customers. This is particularly important because not only must we deliver the prototypes quickly, but they must be manufacturable in volume using the same processes that were used to manufacture the prototype. Those who are experienced with rigid PCBs, flex circuits and rigid-flex designs for medical devices understand that a change in processes or materials can cause a product launch delay due to having to resubmit paperwork or potentially even new samples.

If you are going to learn more details about medical device PCB design, please check and read the content below in this passage for professional knowledge.

What is QMS in medical devices?

QMS is a quality management system that defines processes, policies, and procedures essential for the planning and execution of a particular product. It focuses on customer demands and enhances their satisfaction level. For medical devices, ISO has issued a standard 13485:2016. This standard includes the key business policies, processes, forms, and instructions. Additionally, it includes their sequence, interactions, and resources for conducting business with a medical device manufacturer.

The DMAIC model

Ideally, QMS follows a DMAIC model for any product. This model is the same for populated boards since it covers all the required aspects. Let’s explore this for medical devices:

Define

· Define the scope of risk management activities; explain the medical device and its proposed use.

· Decide roles, responsibilities, and authorities.

· Determine the phases involved in the life cycle.

· Establish guidelines for risk management.

· Assess risk acceptability and risk verification criteria.

· Analyze the risk management activities related to the production and post-production process.

Measure

· Identifications of input and output of the process.

· Determination of data, process map, data collection, etc.

· Specification for devices.

· Measurement of several parameters using scatter plots, pareto charts, etc.

What are the standards of manufacturing medical device PCB?

Medical gadgets and equipment go through more stringent rules and regulations than other electronics. This is because the failure of medical products to function appropriately can cause detrimental impacts, like loss of human life. Thus, each phase of healthcare electronic development undergoes mandatory regulatory oversight to guarantee the best quality and accuracy of the end products.

Medical electronics go through a clear quality management system (QMS) to detect and remove any errors. Acquiescence with such standards is confirmed via various testing routines. The common medical electronic manufacturing standards include:

· The FCC Title 47 rules: These guidelines are made and printed by the Government Printing Office (GPO).

· The Food & Drug CFR Section 807: The FDA’s Center for Devices and Radiological Health (CDRH) regulates companies producing, repackaging, re-labeling, and dealing with medical electronics in the US.

· IEC 60601-1: This guideline outlines the standard aspects of medical electronics.

· IEC 61010-1:It stipulates the standard safety guidelines for electrical equipment and related components.

· IPC 6011: These are basic performance specifications for PCBs.

· ISO 13485 Medical Equipment: This standard is meant for businesses and persons dealing with the design, manufacturing, installation, and servicing of healthcare equipment and gadgets. In addition, certification agencies can use it in their auditing practices.

· ISO 14971:2007: This standard outlines the due process for medical electronic manufacturers to detect any hazard in medical devices.

How to keep the safety of medical device PCB?

This is a case where it pays to work with a PCB manufacturer familiar with high-reliability electronics design (aka Class 3, which we’ll discuss below). Your electronics contract manufacturer should be capable of helping you design to accommodate danger concerns.

The other half of a great safety-first attitude focuses on cleanliness.

Medical devices need to be easy to clean and disinfect. This may influence what kind of enclosure you use -- stainless steel is a natural solution for medical needs.

For example, stainless steel is easy to clean, which is why it is used so often in medical devices. A similar-but-different option is conformal coating, which can protect against:

· Contamination

· Moisture

· Corrosion

· Dust

· Salt spray

Then there’s the downside of disinfecting. Some medical cleaning uses ozone exposure to kill pathogens. Some electronics can degrade in ozone, so component selection is very important here.

One final consideration: Interaction with other medical devices, including noise emission, can be a design concern. You don't want interference with someone's pacemaker, for example.

Industry Category