How to Process PCB First Article Inspection?

By:PCBBUY 07/31/2024 16:18

Printed Circuit Board (PCB) manufacturing is a complex process that requires precise control and verification to ensure the final product meets the necessary quality and performance standards. First Article Inspection (FAI) is a critical step in this process, providing a detailed assessment of a PCB's conformity to design specifications before mass production. This article explores the FAI process for PCBs, detailing its significance, methodologies, and best practices. It includes industry knowledge, data support, equations, and tables to provide a comprehensive understanding.

What is First Article Inspection?

First Article Inspection (FAI) is a formalized process of validating a manufactured part or assembly against design specifications. In the context of PCB manufacturing, FAI involves a thorough inspection and testing of the first produced PCB to ensure it meets all design and manufacturing requirements. This inspection is crucial for:

Identifying defects early in the production process

Validating manufacturing processes and materials

Ensuring compliance with design specifications and standards

What Is the Importance of FAI in PCB Manufacturing?

FAI plays a vital role in the quality assurance process by:

Preventing costly mass production of defective boards

Ensuring that all design and production standards are met

Providing a benchmark for future production runs

Facilitating communication and understanding between manufacturers and clients

What Are the Key Components of PCB FAI?

Documentation and Preparation

1. FAI Checklist

An FAI checklist outlines all the parameters and features that need to be inspected. This checklist is based on the design documentation, including the Bill of Materials (BOM), Gerber files, and assembly drawings.

2. Control Plan

A control plan details the inspection procedures, measurement techniques, and equipment to be used during FAI. It ensures consistency and accuracy in the inspection process.

Inspection Criteria

1. Dimensional Verification

The dimensional accuracy of the PCB is checked against the design specifications. This includes the overall dimensions, hole sizes, pad spacing, and component placements.

2. Material and Component Verification

Verification of materials involves checking the substrate, copper layers, solder mask, and surface finish. Components are inspected to ensure they match the specifications in the BOM.

3. Soldering and Assembly Quality

The quality of solder joints, component orientation, and assembly workmanship are inspected. This includes checking for defects such as solder bridges, cold joints, and misaligned components.

What Is the Detailed FAI Process for PCB?

Step 1: Pre-Inspection Preparation

Review of Design Documentation

Before the FAI begins, all relevant design documents are reviewed. This includes:

Gerber Files: Detailed representations of each PCB layer, used for manufacturing.

BOM: A comprehensive list of components required for the PCB, including part numbers, descriptions, and quantities.

Assembly Drawings: Diagrams showing the placement of components on the PCB.

|

Document Type |

Purpose |

|

Gerber Files |

Layer specifications |

|

Bill of Materials |

Component list |

|

Assembly Drawings |

Component placement guidance |

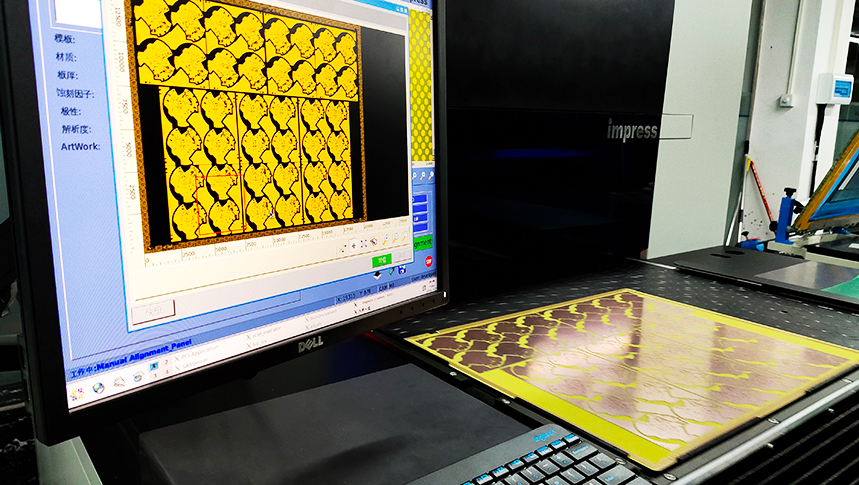

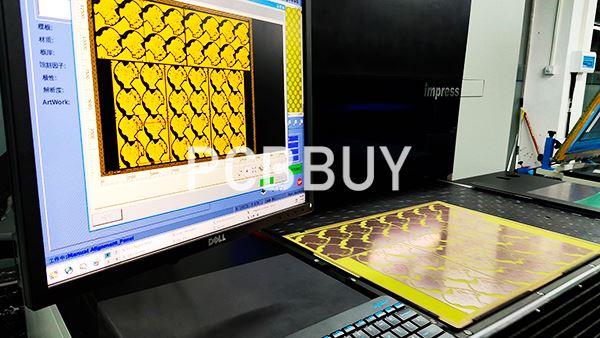

Preparation of Inspection Tools and Equipment

The appropriate tools and equipment for FAI are prepared, including:

Micrometers and Calipers: For measuring dimensions.

Optical Inspection Systems: For detailed visual inspection.

Multimeters and Test Jigs: For electrical testing.

Step 2: Visual Inspection

Surface and Finish Quality

The surface of the PCB is inspected for:

Solder Mask: Checking for uniform coverage, thickness, and defects.

Surface Finish: Verification of the type and quality of the finish, such as HASL, ENIG, or OSP.

Component Placement and Soldering

The inspection includes:

Component Orientation: Ensuring correct placement and orientation according to the assembly drawings.

Solder Joint Quality: Inspecting for adequate solder coverage, wetting, and joint strength.

|

Inspection Aspect |

Criteria |

|

Criteria |

Coverage, thickness, defects |

|

Component Placement |

Accuracy, orientation |

|

Solder Joint Inspection |

Coverage, wetting, joint integrity |

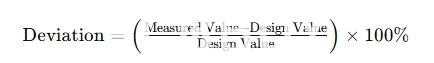

Step 3: Dimensional Verification

Measurement of PCB Dimensions

Key dimensions such as board thickness, hole sizes, and pad spacing are measured and compared with the design specifications.

Hole and Pad Size Verification

Measurement of hole diameters and pad sizes ensures that they meet tolerances specified in the design documents.

|

Dimension |

Tolerance (%) |

Measured Value |

Design Value |

Deviation (%) |

|

Board Thickness |

±10% |

1.60 mm |

1.50 mm |

+6.67% |

|

Hole Diameter |

±5% |

0.20 mm |

0.21 mm |

-4.76% |

|

Pad Size |

±2% |

1.00 mm |

1.02 mm |

-1.96% |

Step 4: Electrical Testing

Continuity and Isolation Testing

Continuity Testing: Ensures that electrical connections are intact.

Isolation Testing: Verifies that there are no unintended connections between different circuits.

|

Test Type |

Criteria |

Result |

|

Continuity |

All connections must pass |

Pass/Fail |

|

Isolation |

No shorts between traces |

Pass/Fail |

Functional Testing

Functional Test: Verifies the PCB’s functionality by simulating operating conditions.

Power-Up Test: Ensures that the PCB can power up and operate as intended without issues.

Step 5: Documentation and Reporting

FAI Report

An FAI report documents all inspection results, including:

Visual Inspection Findings

Dimensional Measurement Results

Electrical Test Outcomes

Any Deviations or Non-Conformities

Non-Conformance Reporting

If any discrepancies or defects are found, they are documented, and corrective actions are proposed. This may include process adjustments or design changes.

Best Practices for Effective FAI

Continuous Improvement

FAI should be part of a continuous improvement process, where feedback from FAI results is used to enhance design, materials, and processes.

Training and Skills Development

Ensure that personnel conducting FAI are adequately trained and familiar with the latest standards and inspection technologies.

Use of Advanced Inspection Technologies

Incorporate advanced inspection tools such as automated optical inspection (AOI) systems, X-ray inspection, and 3D measurement systems to enhance accuracy and efficiency.

Conclusion

First Article Inspection (FAI) is an essential process in PCB manufacturing, ensuring that the first produced boards meet all specified requirements before mass production. By following a structured FAI process, manufacturers can identify and correct defects early, improve product quality, and ensure customer satisfaction. The adoption of best practices, continuous improvement, and advanced inspection technologies further enhances the effectiveness of FAI.

References

1. IPC-A-600, "Acceptability of Printed Boards," IPC, 2019.

2. IPC-6012, "Qualification and Performance Specification for Rigid Printed Boards," IPC, 2020.

3. J. H. Lau, "Advanced Soldering Techniques," McGraw-Hill, 2002.

4. C. F. Coombs, "Printed Circuits Handbook," 7th Edition, McGraw-Hill, 2016.

5. K. Gilleo, "Area Array Packaging Handbook: Manufacturing and Assembly," McGraw-Hill, 2002.

Industry Category