How to Promote Pitch in PCB Design in 5 Tips?

By:PCBBUY 03/27/2023 14:01

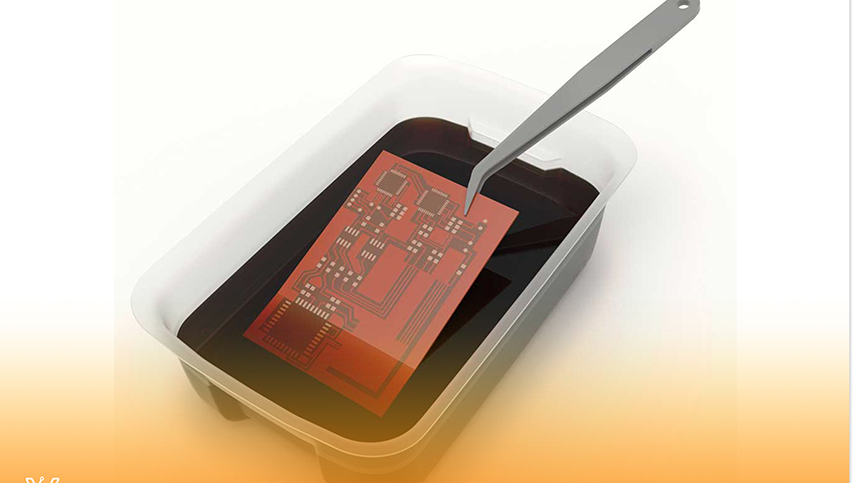

In printed circuit boards pitch is the center-to-center distance of drill holes, BGA pads or component connectors. If grids are smaller than 0.7mm or copper structures smaller than 150µm the board is fine pitch.

In this passage, we are providing all the details about Pitch in PCB. If you are searching for the information of Pitch in PCB, please check and read the content below in this passage.

What are the main factors pitch in PCB design?

With most electronic equipment trending towards compact designs, printed circuit boards inside them must hold a substantial number of components per unit square area. With components packed so close together, designs are usually on the extremes and manufacturers must follow tight PCB fabrication tolerances. Another feature of these designs is the use of components with very high pin count, leading to very fine pitch between the pins. This is the origin of the name fine-pitch PCB assembly, another name being high-density PCB assembly.

At Rush PCB Inc., we design and assemble fine-pitch PCBs. As per our experience, following a few simple generic rules can significantly increase the chances of a successful assembly of fine-pitch circuit boards:

· Designing the board

· Challenges in layout

· Selecting proper components

· Defining the board size

· Component placement

How to design pitch in PCB?

Generally, a high-density application would include very fine-pitch components, which also drives fabrication costs and capabilities. The smaller the component, the smaller its pads (and its actual physical body) which require pick and place machines to be very accurate. When use leadless and grid-array based components, it may require X-ray inspection during the assembly process.

Designing fine pitch circuit boards and applications requires a close relationship between the designer and the board vendor, for a lot of decisions and details depend on the capabilities and equipment offered at the PCB assembly services facility. The PCB supplier should also provide general guidance on risk that can be given by CAM operators and other board house technical representatives.

What are the components of pitch in PCB?

Electronic components for fine-pitch PCB assembly can be SMDs, ICs, BGAs, QFPs, and so on, as long as the center-to-center distance between the adjacent pads or solder balls is within 0.5mm. Surface mount devices for fine-pitch assembly are usually 0201, 0402, and sometimes 0603. For fine-pitch components that have solder balls, such as fine-pitch BGAs (FBGAs) and ICs, the distance between the adjacent solder balls is within 0.5mm. For example, the distance between the adjacent pins of the fine-pitch IC as below is 0.3mm.

What are the considerations of pitch in PCB design?

A fine pitch PCB implies printed circuit boards having a considerably high number of components for every square inch. Therefore, components prove close together with the board’s design guidelines pushing the fabrication limits of the printed circuit board fabrication. A fine pitch PCB also gets inferred as a high-density PCB.

Before we get into the design and assembly process, it becomes imperative to understand a few things about high pitch PCBs, especially regarding crucial components.

· Screw terminal 2.54 mm pitch. The screw terminal component is crucial and comes as a simple two-position screw terminal containing 2.54mm pitch pins. Such a pitch allows it to align with the typical 0.1-inch perf boards.

· 2.54 mm screw terminal blocks. It comes as a side-entry screw terminal block and contains a 2.54mm or 0.1-inch pitch. It can become an excellent alternative to the typical 0.1-inch female or male headers that most printed circuit boards feature. The reason this becomes possible entails the terminals proving capable of releasing and holding wires through adjustment of screws, which allows for temporary connections to the PCB.

· 2.54mm terminal blocks. The 2.54 terminal block is an important component in a PCB that helps keep loose wiring in check when making PCB-to-wire connections. The spacing allows them to fit perfectly into breadboards (solderless).

· Veroboard pitch. It implies a 2.54mm hole size drilled into the copper track rows that feature this PCB design.

What are the advantages of pitch in PCB?

Fine-pitch PCB assembly saves the PCB space dramatically, and this allows the PCB to carry more components. Products will have more functions and higher performances.

Fine-pitch components such as FBGAs package more circuits than the normal TSOP (thin small outline package) in the same size. Fine-pitch PCB assemblies also have better thermal dissipation, because solder balls of the fine-pitch components have more contact areas with the PCB than the normal component pins do.

Industry Category