How to Properly Route a PCB?

By:PCBBUY 09/08/2021 09:15

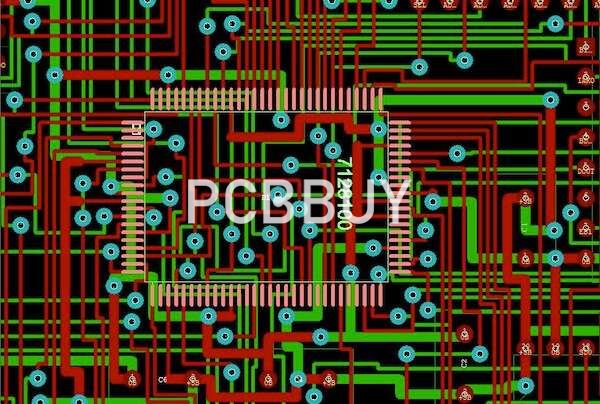

There are several during the process of PCB manufacturing an every step of them is very important. Routing traces and vias on a PCB design is often thought of as a simple task. Routing copper traces is much easier when you can automate compliance with your PCB design rules using the best PCB layout tools.

In this passage, we are going to provide you everything about PCB routing working principles methods. If you are curious about this topic, you can check and read the content below.

What are the technologies of PCB routing?

When designing your PCB layout, there are many considerations that must be incorporated into your choices and decisions. A popular way to integrate these concerns is to adopt a design perspective that helps you organize your design choices. For example, if you design your based on board type, you may place a premium on signal integrity (SI) or power integrity (PI). Alternatively, if manufacturability is the most important consideration, then design for manufacturing (DFM) guidelines and tolerances may supercede other issues. Regardless of the perspective you choose, traces are typically viewed as a group and routing them is considered a collective exercise.

A collective approach is good for specifying a general set of rules or guidelines for routing the traces on your board. However, it does not encourage you to make the best routing choice for individual traces. Conversely, by viewing each trace separately, we can define the best PCB routing techniques to follow when a given situation exists, as listed below.

Trace width expansion

Trace width expansion is always restricted. This may be to ensure adequate solder masking exists, to reduce crosstalk between traces, or other reasons. If the trace needs to be modified for current capacity reasons, the best course of action is to increase copper weight.

Obstacles along trace

This is a common problem where either components or traces obstruct the desired path. Typically, changing component location is far too complex and it is easier to use vias and route under traces than move them. When routing around obstacles, it is best not to use sharp angles (≥ 45° is recommended). For routing under obstacles, you usually should choose the most direct or shortest route and least complex via type.

Differential pair

Differential pairs are a special class of traces. As such, they should be routed as if they were a single trace. This means that their lengths and widths should be the same, and the distance between them should remain constant. Therefore, any changes to one should also be performed to the other, if at all possible. If not possible, then you use a meander, which is an arbitrary trace path used to match the other trace’s length.

Adjacent layer

You should avoid running signals on adjacent layers, if possible. Instead, a ground plane should be placed between signal layers. However, if the signals must exist on adjacent layers, they should be routed orthogonal to each other to prevent coupling. This is true for adjacent layers in the stackup and for two-sided boards.

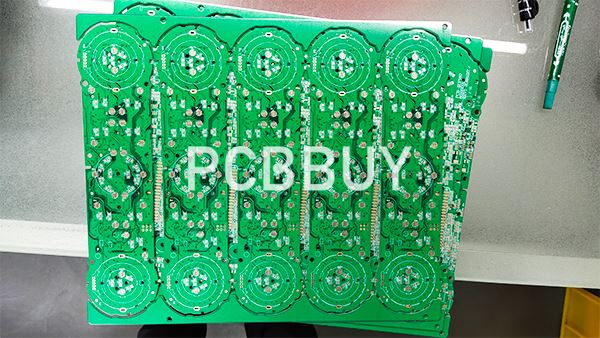

How to route multilayer PCB?

When designing PCB, most engineers would like to complete the high-signal routing by using multi-layer boards. Besides its role as the core of PCB, this type of multi-layer board is also capable of decreasing the circuit interference, which is a main method for engineers confronted with such a problem.

When designing the high-speed signal circuit on PCB based on the utilization of multi-layer board, engineers need to shrink the board size by rationally determining the number of layer, to make the best use of the middle layer for shield setting to realize the nearby ground, all of which can effectively decrease the parasitic inductance, shrink the signal transmission length, reduce the cross interference between signals and so on. All of these methods are quite beneficial for the reliability of high-speed signal circuit.

Apart from the methods above of increasing the reliability of PCB signal transmission with the help of multi-layer board, some authority data shows that when the same material is used, the noise generated by four-layer board is 20dB lower than that by 2-layer board. For the lead bending, the fewer the bending appears, the better it'll be. It's best to use the whole line and when bending is required, a 45 degree line or an Arc line can be used so that the emission towards outside will be cut down from high-speed signal and mutual coupling and both the radiation and reflection will be decreased as well.

What are the considerations of PCB routing?

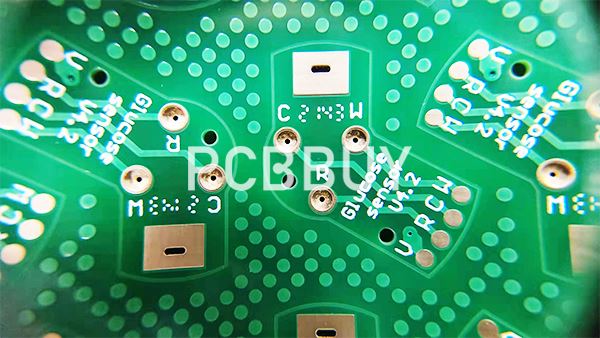

Constraints and rules are used in PCB design for a number of reasons. They will help you to organize your design and communicate important information between the schematic and the layout. Primarily, though, they are used to prevent manufacturing problems and to ensure the electrical performance of the circuit board. Here are some issues that constraints are designed to address:

Manufacturing Problems:

Components that are placed too close to each other or oriented incorrectly may be difficult to assemble or solder correctly. Additionally, auto-insertion machinery may not be able to place the parts as needed, and technicians doing manual assembly may not be able to fit their tools and solder materials into the tight areas.

Metal on the circuit board that is too close to other metal objects may also cause problems during the manufacturing process. Solder slivers can form, causing intermittent shorts, which are difficult to find and correct. Solder can also bridge between traces or pads causing direct shorts.

Electrical Performance:

Traces used to conduct power that aren’t wide enough may be inadequate for the amount of current that they are carrying. Some traces also must have exact widths to control their impedance. Other traces need to be routed to a specific length or to match the length of similar nets. Differential pairs must be perfectly routed side-by-side.

It used to be that you could take a PCB design, throw it into the auto-router, and end up with a completely routed board that worked perfectly. That is no longer the case. Without the proper care in trace routing widths, spacing, lengths, and topologies, you may end up with a plethora of signal integrity problems.

Industry Category