How to Protect PCB from ESD through 5 Effective Tips?

By:PCBBUY 10/25/2021 10:35

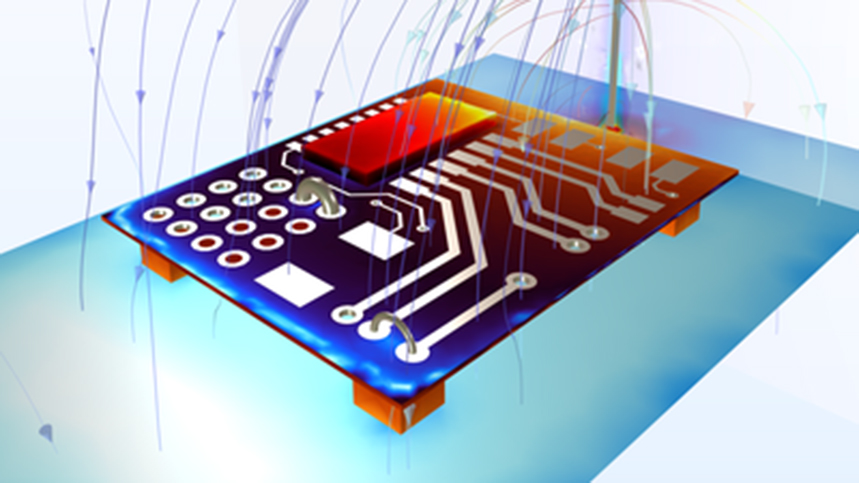

ESD is a tiny amount of lightning, similar to what happens during thunderstorms, only in a miniature form. According to the laws of physics, the electromotive force causes a massive amount of current flow through a path offering the lowest resistance. In most cases, the discharging current travels to ground via the metal chassis or frame.

Are you going to learn the methods to protect PCB from ESD damage? If you are interested in PCB ESD damage, please check and read this passage for more information.

1. What are the damages caused by ESD to PCB?

When a PCB assembly comes close to any object that has a charge, there is a possibility of an ESD. This depends on the electromotive force between the two and the distance separating them, with the greatest chance of an ESD taking place when the two touch.

Although manufacturers build different protection mechanisms within ICs, ESD can as much as totally ruin an IC. This damage may be of two types—latent or catastrophic. When a device suffers latent damage due to ESD, it may be partly degraded, and continue to run. However, the device becomes unreliable as its lifetime reduces, and its operational behavior affected.

A bare PCB may also suffer latent damage. For instance, there can be an electrical discharge from one neighboring track to another, if the latter is connected to ground. The discharge can char the top layer of the PCB insulation, causing a partially conducting path. This can affect the performance of the circuit after assembly.

2. When does ESD affect on PCB?

Electrostatic discharge (ESD) occurs when two objects with different charges get close enough, or charged enough, to break down (ionize) the dielectric between them. For consumer products, ESD and dielectric breakdown in air usually occurs when the electric field between two points is greater than 40 kV/cm. Things like air pressure, temperature, and humidity will affect this electric field strength. For example, high humidity in some environments can cause the air to be more conductive, which will dissipate some charge and increase the voltage required to ESD.

One common misconception is that a specific voltage is needed to cause ESD. This is not exactly correct; the voltage required to produce ESD is dependent on the voltage between two points and the distance between those points. This is why, in PCBs, we have a limits on the clearance between conductors (creepage and clearance) as specified in the IPC-2221 standards.

3. How to protect PCB from ESD through components controlling?

Component identification: Although sensitive devices are pre-packaged from the manufacturer in static controlled containers, it is still important for the PCB CM to identify which components are more sensitive than others, and handle them appropriately. Not only is this important for ESD, but for moisture-sensitive parts as well.

Component handling: Once the components are in-house, the PCB CM needs to follow documented procedures for handling them. This includes their use within designated ESD protected areas of the manufacturing floor and ensuring that assembly technicians are trained and prepared for working with these parts.

4. How to protect PCB from ESD through layout?

Apart from this, a whole lot of PCB Layout practices can go a long way in protecting PCB. These include:

Remove circuit loops

Loops can lead to unwanted current. This in turn affects performance as unwanted current spikes can enter any loop. Due care therefore needs to be taken to ensure there are no loops.

Utilize ground plane layers in the printed circuit board

Using a ground plane within a circuit board can go a long way in helping to reduce loops and therefore unwanted current.

Reduce line lengths

Reducing line length in effect reduces the radiated energy received and therefore reducing the spikes from electrostatic discharges.

Reduce parasitic inductance

Protection circuits can only work effectively if parasitic inductance levels are low. In turn parasitic inductance can be reduced by keeping the line lengths short.

5. How to handle PCB from ESD damage?

ESD damage to unprotected sensitive devices may occur at any time. ESD events can occur far below the threshold of human sensitivity. Follow this sequence when it becomes necessary to install or remove a circuit board:

After you are connected to the grounded wrist strap, remove the circuit board from the frame and place it on a static controlled surface (grounded floor or table mat).

· Remove the replacement circuit board from the static-shielding bag or clamshell and insert it into the equipment.

· Place the original board into the shielding bag or clamshell and seal it with a label.

· Do not put repair tags inside the shielding bag or clamshell.

· Disconnect the wrist strap.

Industry Category