How to Prototype PCB with 5 Professional Skills?

By:PCBBUY 10/10/2021 10:06

A PCB prototype board refers to a simple printed circuit board with several receptacles with a grid where you can place components and wire them together in an organized fashion. It is pretty difficult to prototype a PCB, there’s a wealth of online resources and software solutions to help you build your very first circuit board.

Designers use PCB prototype boards to prove the concept of an electrical circuit before sending the final product for manufacturing. Electrical circuits tend to be highly sensitive to various component values leading to system performance variations. In this passage, we will focus on the professional skills of PCB prototyping, if you are interested in this topic, please check and read the content below for more information.

How to process the PCB prototyping with 5 tips?

1. Why to process PCB prototyping?

We recommend that you create a prototype before ordering a full production run of a new PCB design. We make sure our prototype PCB service is fast and user-friendly so you can test your board without delay or hassle. Here's what PCB prototyping enables you to do:

• Detect design flaws early in the production process before you invest significant capital

• Cost-effectively test multiple designs

• Get an accurate portrayal of how your board will function

2. What are the preparations before the PCB prototyping?

Before you have your PCB prototype built up, you will need to have the correct documentation in place. Focus your attention on creating readable and easy-to-follow documentation to ensure your design is correct. Your PCB manufacturing documentation should never be an afterthought. This is particularly relevant when your designs are for innovative or proprietary technologies.

To ensure your PCB manufacturing documentation is correct, and to make the process as easy as possible for yourself, you can follow these steps:

· Use templates to save time

· Be aware that all edits and deletions have been made when using copies based on older documentation

· Make sure that you have a review and sign-off process to ensure accuracy

· Ensure all of your documentation matches the completed design.

· Make sure part numbers are up-to-date.

3. What is the process of PCB prototyping?

PCB prototypes are early samples of products built with the sole purpose of testing design ideas to see if they work. Although most prototypes, in general, are made to test basic user functionality, engineers require somewhat, if not entirely, functional PCB prototypes to check the complete functionality of designs.

Engineers and designers use different types of PCB prototypes to test different design aspects. Throughout a project, your design teams may use several PCBs at various stages of their design processes. Example of these prototypes include:

· Visual Models: They illustrate the physical aspects of PCB designs and show the overall component structure and shape. As the initial prototypes in your design process, engineers use visual models to review and communicate the design easily and affordably.

· Proof-of-Concept Prototypes: These prototypes focus on the replication of the primary function of PCB boards without carrying all of the final product’s capabilities. They show viability.

· Working Prototype: These are functioning boards containing all the planned functions and features of the final product. They help identify problems and weaknesses in designs but rarely represent what or how the final product will look like when finished.

· Functional Prototype: Designers make these to resemble the final product. They provide the most accurate idea of the final design.

4. How to guarantee the quality of prototype PCB?

Of course, product quality is always important. As a company prepares to bring a product to market, there will inevitably need to be a tremendous amount of focus on ensuring the item in question meets expectations and standards. Any shortcomings need to be addressed.

Circuit board quality can have a major impact here. How? By helping companies narrow down the list of potential problems. After all, most people aren’t going to look at the printed circuit board as the issue within a malfunctioning prototype until they’ve exhausted other potential factors. By the time the investigation leads to the PCBs, it’ll be too late to avoid substantial delays.

5. How to choose PCB manufacturer to process prototyping?

Not all PCB fabrication and manufacturing professionals specialize in quickturn. Don’t be afraid to ask for specific figures regarding on-time delivery, as well as the percentage of circuit boards manufactured within tight turnaround times. Ask how different layers, board types and lead times will affect delivery.

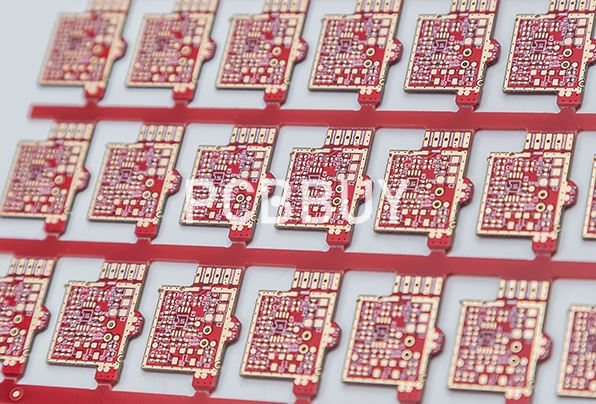

PCBBUY Technology Co. Ltd is a smart factory specialized in quick turn PCB prototyping. PCBBUY service center is located in the beautiful city - Hangzhou, China, and its factory is located in the southern gate of China - Zhuhai, Guangdong. There are production lines of Single PCB,2 layers PCB,4 layers PCB,6 layers PCB,8 layers PCB and 1000mm PCB. We has passed the SGS, RoHS, UL and other authority certification, the fastest can achieve 24 hours of delivery.

Industry Category