How to Recognize the Functions of Stiffener in PCB Manufacturing?

By:PCBBUY 04/19/2023 16:02

PCB stiffeners are not an original part of a PCB. They are something added later to the board as support. They have many jobs, from strengthening parts of the board to allowing for better handling of the board. It essentially is a way to make a PCB circuit board more durable so that it can stand up to the demands put upon it through manufacturing and use.

Do you know the definition and the function of PCB stiffeners? Please check and read the content below for more information about PCB stiffeners in this passage.

What is the basic information of PCB stiffeners?

Flexible PCBs have many advantages like the capability to bend, twist, and fold. However, it is challenging to add/solder components and interconnects to these boards. A PCB Stiffener can be used to make a part of the board more stable/rigid so that it becomes easier to add/solder components or interconnects to the stiffer parts of the board. PCB stiffeners are usually not an integrated part of the PCB. They are only used to provide mechanical support to certain parts of the board.

Other advantages of PCB stiffeners include the reinforcing of solder joints, an increase in abrasion resistance and better handling of the board f

The PI stiffeners are a cheaper alternative to FR

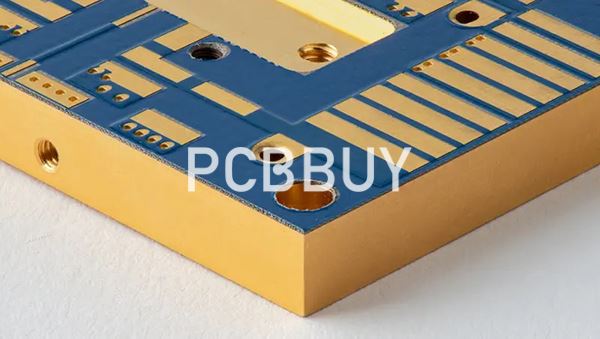

4. On the other hand, if manufacturers are looking for heat sinking properties and better rigidity, they use stainless steel or aluminum stiffeners. or automated pick-and-place component placement and soldering.

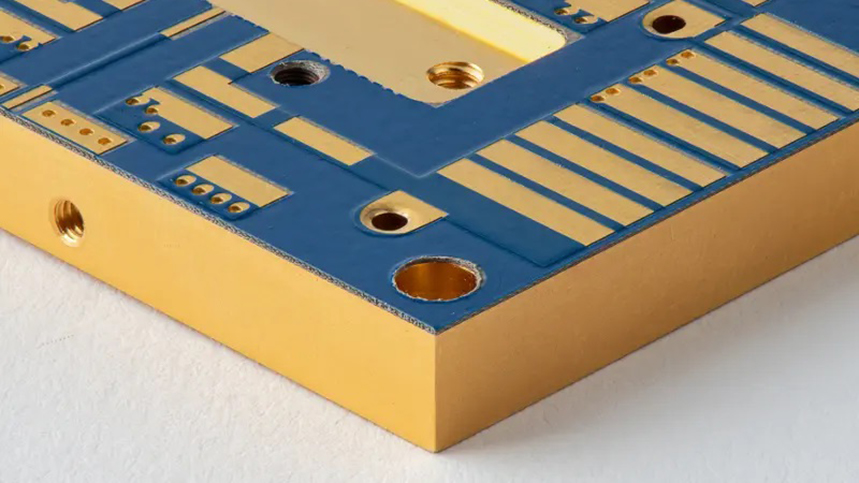

PCB stiffeners are usually made from FR4, Polyimide or aluminum. The thickness of FR-4 stiffeners varies from 0.003"(0.08 mm) to 0.125" (3.18 mm). The polyimide stiffeners are available with a thickness of 0.005" (125μm), 0.001" (25μm), 0.002" (50μm), and 0.003" (75μm). Polyimide stiffeners are usually a low-cost alternative to FR-4 as they are punched on a die instead of routed with a drill bit. To get better rigidity and heat sinking properties, aluminum stiffeners are used.

What are the differences among PCB stiffeners and other material?

There are 3 main types of PCB stiffeners - Polyamide (PI) stiffener, FR4 stiffener, and aluminum/stainless steel stiffener. These materials are most commonly used on projects requiring increased stiffness and heat dissipation.

Polyamide (PI) Stiffener

PI stiffeners are commonly used to increase the thickness of the ZIF connector, where finers contact and provide full support. This way it allows tolerances in bending thickness and contours the component at the contact. The finger area bend thickness tolerance is typical +/- 0.002" and the width profile is +/- 0.003". Also, PI stiffeners are used to limit the bending ability of specific PCB areas to prepare an installation in the final assembly. The most common area to enhance would be the hole locations to provide additional wear resistance whenever wear problems occur.

Polyamide stiffener is an excellent option for solder resistance and high bond strength. The most preferred locations for stiffeners application are on the backside of the insertion gold fingers. Sometimes you can simply pick the part of the PI stiffener that is not laminated or attached to the FPC body and easily insert the flexible printed circuit connector fingers into the ZIF socket or connector.

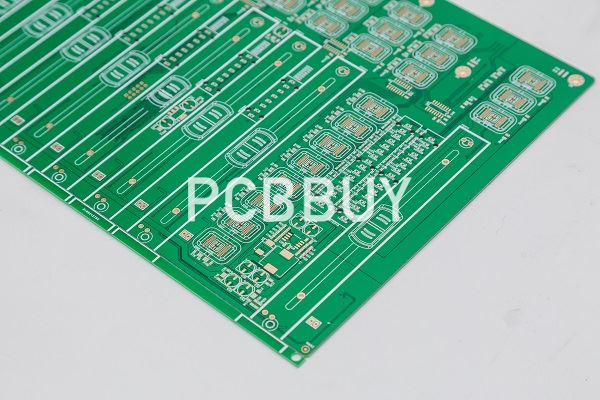

FR-4 Stiffener

FR-4 can be the CCL of the rigid printed circuit board and is the most common material used for the PCB stiffeners application in and flex circuits. The main purpose of adopting an FR4 stiffener includes:

1. Providing flat enough support when the flexible PCB is in the pick-and-place and reflow processes.

2. Plated-through hole (PTH) components, it is important for the stiffeners to be placed on the same side of the flex PCB in which the components are inserted to allow direct access to solder pads. In some cases, the customer wants to save money in the turnkey process of the project assembly, and in order for manufacturers to do so, they add an FR-4 frame on the border of the panelized PCB to successfully replace the SMT carrier.

Why Do Flex and Rigid-Flex PCBs Need Stiffeners?

To really understand PCB stiffeners, we need to look at flex and rigid-flex PCBs.

A flexible PCB has a malleable base material. It allows you to design the circuitry to fit the device. The need for PCB stiffeners on flex boards is evident due to the nature of the design. There will always be areas that require more support than the base material can supply.

What is a rigid-flex PCB? This type of board has some areas of strengthened base, while others are malleable. Areas on the board that require extra support will not bend, while the areas that do not need support can bend.

Since the manufacturer builds support into the printed circuit board, you may think this type of board will not need stiffeners. However, that is untrue. Even a rigid-flex board can benefit from extra strengthening once all components are in place.

You may find that answering the questions, how do you make flex PCB, and how are rigid-flex PCBs made, can make this clearer because you will see how each board functions and why someone may feel the need to add in a PCB stiffener.

Industry Category