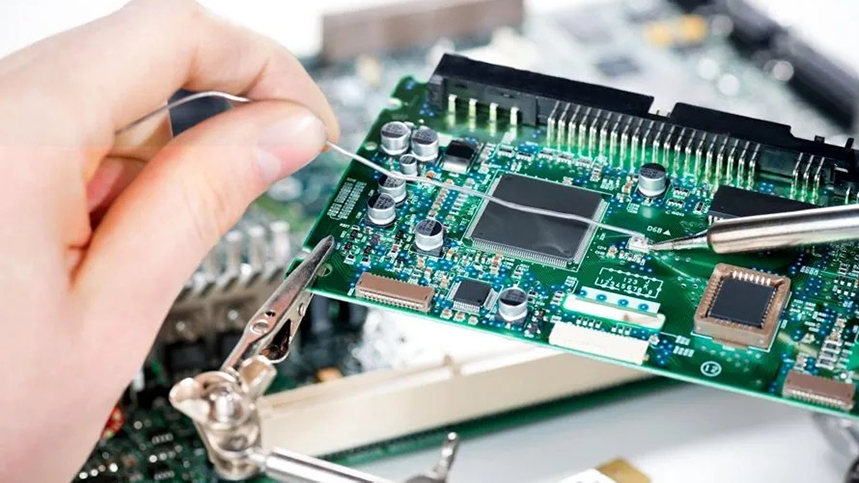

How to Repair Damaged PCB Pad with 5 Effective Tips for PCB Beginners?

By:PCBBUY 11/27/2021 09:39

First of all, let’s define exactly what a “pad” is. A pad, also known as a “land,” is the exposed area of metal on a circuit board that the lead of a part will be soldered to. Multiple pads are used to create the component footprint, or land pattern, on the printed circuit board. To avoid these problems, it is important to use acceptable PCB pad size guidelines in the construction and placement of pads and their associated footprints.

In this passage, we are going to provide the information about repairing the methods of PCB pad. If you are curious about the PCB pad repairing, please check and read the content for more professional knowledge.

How to prepare for repairing PCB pad?

There are certain things that you should have before you have made up your mind to repair a PCB. The list of these elements are as follows:

· Clean, lint-free cloth

· Flux

· A microscope and if you have magnifying glasses then it works wonders

· Soldering iron and solder

· C-clamps

· Handful of Toothpicks

· Wipes and isopropyl alcohol

· A safe, flat- polished ESD cutting surface

· X-Acto knife

· Adhesive copper tape

· Circuit frame

Now when you have all the materials to do this repair you can start with the steps to repair PCB pads.

How to repair PCB pad step by step?

Once you’ve collected all of the required materials, carefully follow these 10 steps to complete the PCB repair process:

· Cleaning the damaged pad: Thoroughly clean the damaged area with isopropyl alcohol, and follow up by drying the area with a lint-free cloth or compressed/canned air.

· Removing the damaged pad: Use an X-Acto knife to carefully cut away the damaged pad.

· Cleaning the area around/under the damaged pad: After removing the pad, clean the area immediately around/under the pad. Be sure to thoroughly remove any damaged or burned laminate from the area.

· Removing the solder mask: Using a toothpick, remove any existing solder mask from the conductor.

· Repeat cleaning the area: Using isopropyl alcohol, conduct another thorough cleaning of the area. Follow up by drying the area with a lint free cloth or compressed/canned air.

· Tinning the conductor: Select the appropriate solder alloy to tin the conductor area where the conductor will be attached.

· Selecting the appropriate circuit frame: Using an X-Acto knife, cut out a new conductor from the appropriate circuit frame.

· Tinning the new pad/conductor: With the appropriate solder alloy, tin the pad/conductor area that will overlap the original trace. Now, mix up a small amount of epoxy resin and hardener, and apply it to the area on the PCB. You can either use open air to cure it, or you can use an oven — but be sure to follow all manufacturer guidelines.

· Soldering the new pad/trace to the conductor: Use Kapton tape to place and hold the replacement pad. Use the appropriate solder alloy to make a lap joint.

· Clamping and curing: Clamp the new pad/trace in place and cure. Once cured, remove the clamp and clean the pad/trace with isopropyl alcohol. Note: This is a good time to run a quick electrical continuity test. Once everything checks out, you may also want to envelop the edges of the new pad/trace with epoxy or solder mask to give the area increased mechanical strength.

Standard 2-part epoxy can contaminate the surface of the connector, creating an insolative barrier. 2-part conductive epoxy is a great solution for making repairing damaged pads. This type of epoxy contains conductive material, so when cured, it forms a very strong and highly conductive bond, similar to a solder joint.

Epoxy repair method involves repairing pads using a two-part epoxy adhesive system and replacement plated pad. For you to undertake this method you must clean the pad properly for it adhere well with the repair equipment. You must also inspect all the tools so that you can do the procedure properly. To begin this process, you will have to remove the pad using a knife and cut a small part of the connecting circuit.

Industry Category