How to Understand Aluminum PCB of Principles Applications and Comparative Analysis?

By:PCBBUY 09/25/2024 16:57

Aluminum Printed Circuit Boards (PCBs) have become a cornerstone in modern electronics, particularly for applications requiring efficient heat dissipation and enhanced durability. As electronic devices become more compact and powerful, the demand for advanced thermal management solutions has surged. This article provides an in-depth examination of aluminum PCBs, discussing their composition, operational principles, advantages, applications, and a comparative analysis with traditional FR-4 PCBs.

1. What are Aluminum PCBs?

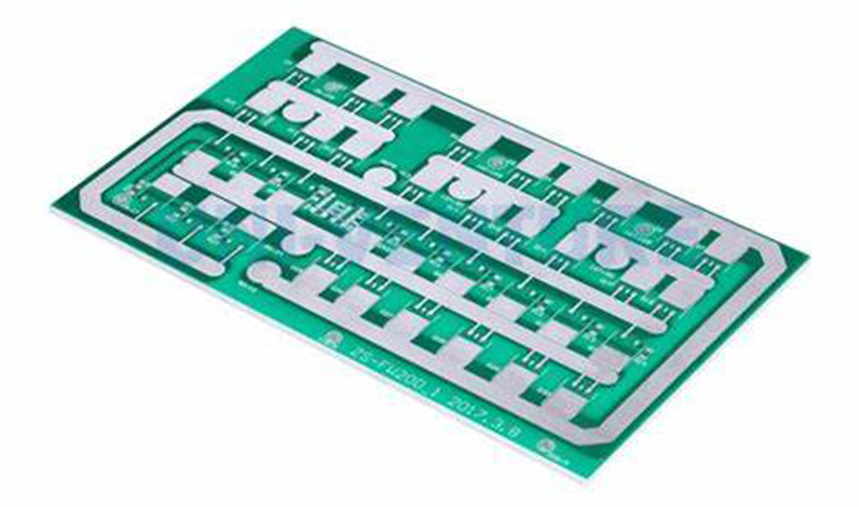

Aluminum PCBs are a type of metal core PCB, primarily characterized by the use of aluminum as the substrate material. Unlike standard FR-4 PCBs, which are made from a composite of fiberglass and epoxy resin, aluminum PCBs are designed to effectively conduct heat away from electronic components, ensuring their reliability and performance.

1.1 Composition and Structure

An aluminum PCB typically consists of three primary layers:

Copper Layer: This is the top conductive layer where the electronic circuits are etched.

Dielectric Layer: An insulating layer made from materials such as epoxy or polyimide, which separates the copper layer from the aluminum base while ensuring electrical insulation.

Aluminum Base Layer: The bottom layer that acts as a heat sink, providing mechanical support and excellent thermal conductivity.

1.2 Properties of Aluminum PCBs

To provide a clearer understanding of aluminum PCBs, we can compare them to traditional FR-4 PCBs. The following table outlines key properties:

|

Property |

Aluminum PCB |

FR-4 PCB |

|

Thermal Conductivity |

200-300 W/m·K |

0.3-0.4 W/m·K |

|

Weight |

Heavier |

Lighter |

|

Cost |

Higher |

Lower |

|

Mechanical Strength |

High |

Moderate |

|

Maximum Operating Temperature |

Up to 150 °C |

Up to 130 °C |

2. Principles of Operation

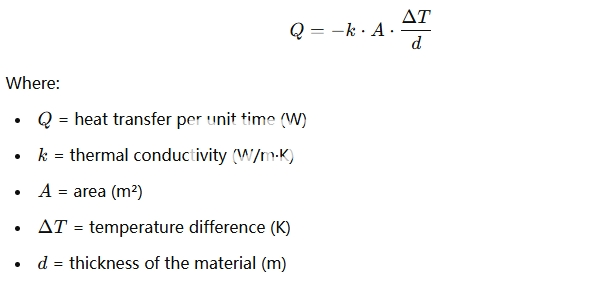

2.1 Thermal Management

One of the key functions of aluminum PCBs is their superior thermal management capabilities. High thermal conductivity allows heat generated by components to be dissipated effectively, preventing overheating and potential failure. This can be explained by Fourier’s law of heat conduction, which states:

2.2 Electrical Properties

The electrical properties of aluminum PCBs also play a significant role in their effectiveness. The copper layer is usually available in thicknesses ranging from 1 oz to 10 oz, allowing for adequate current carrying capacity. The dielectric layer material is selected based on application needs, often utilizing materials like polyimide for high-temperature applications.

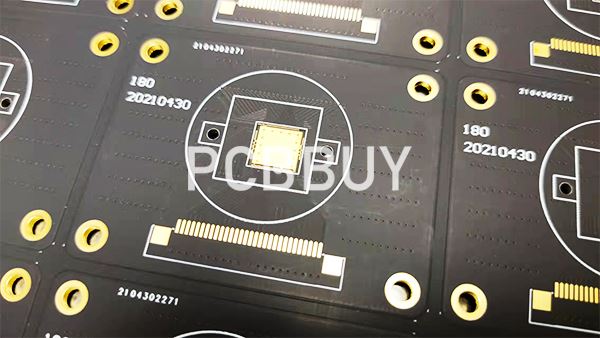

2.3 Manufacturing Process

The manufacturing process for aluminum PCBs involves several critical steps:

1. Design: The design is created using CAD software, taking into account electrical and thermal specifications.

2. Layer Preparation: The copper layer is etched to form the circuit pattern, while the dielectric layer is applied.

3. Bonding: The copper and dielectric layers are bonded to the aluminum base using thermal bonding techniques.

4. Drilling and Plating: Holes for vias and components are drilled, followed by electroplating for electrical connections.

5. Surface Treatment: The PCB is treated with surface finishes like HASL or ENIG for solderability.

3. Advantages of Aluminum PCBs

3.1 Enhanced Thermal Management

The primary advantage of aluminum PCBs lies in their thermal performance. They are specifically designed to manage the heat generated by high-power components, making them ideal for applications like LED lighting and power electronics.

3.2 Durability and Mechanical Strength

Aluminum PCBs offer high mechanical strength, which enhances their durability during manufacturing and handling processes. This is particularly beneficial in applications subjected to mechanical stress or environmental extremes.

3.3 Lightweight Design

Despite the added weight of aluminum compared to FR-4 materials, the overall design can lead to significant weight savings in larger applications, particularly in LED lighting fixtures.

4. Applications of Aluminum PCBs

Aluminum PCBs are utilized in a wide range of industries and applications, including:

4.1 LED Lighting

The LED industry is the largest market for aluminum PCBs. The excellent thermal conductivity helps to prolong the lifespan of LEDs, maintaining high efficiency and brightness.

4.2 Automotive Electronics

With the rise of electric and hybrid vehicles, aluminum PCBs are increasingly used in applications such as battery management systems, power supplies, and electric motor controls, where heat dissipation is crucial.

4.3 Power Supplies

Aluminum PCBs are frequently employed in power supply circuits, where heat generated by transformers and voltage regulators needs to be efficiently managed.

4.4 Telecommunications

In telecommunications, aluminum PCBs are used in high-frequency applications where thermal management is essential for maintaining signal integrity.

5. Comparative Analysis of Aluminum PCBs and FR-4 PCBs

Understanding when to use aluminum PCBs versus FR-4 PCBs is crucial for engineers. The following table outlines the pros and cons of each type of PCB:

|

Feature |

Aluminum PCB |

FR-4 PCB |

|

Cost |

Higher |

Lower |

|

Thermal Performance |

Excellent |

Poor |

|

Mechanical Properties |

High |

Moderate |

|

Weight |

Moderate |

Light |

|

Suitable Applications |

High-power, LED |

General electronics |

5.1 Cost Analysis

While aluminum PCBs are generally more expensive than FR-4 PCBs, the investment can be justified by their enhanced performance in thermal management and reliability, particularly in high-stakes applications.

5.2 Performance Evaluation

In applications where heat generation is a critical concern, the performance of aluminum PCBs far exceeds that of FR-4. A comparative study found that aluminum PCBs can operate at temperatures up to 150 °C, while FR-4 PCBs are limited to around 130 °C.

5.3 Environmental Impact

The use of aluminum PCBs can also be seen as environmentally favorable due to the potential for recyclability and reduced failure rates, which leads to less electronic waste.

6. Future Trends and Innovations

The field of PCB manufacturing is constantly evolving, with trends focusing on improving thermal management, reducing costs, and enhancing design flexibility. Key areas of innovation include:

Advanced Materials: Research is ongoing into new dielectric materials that can further enhance thermal performance and reliability.

Integrated Heat Sinks: Future designs may incorporate integrated heat sinks into the aluminum base, further improving thermal management.

3D Printing: The potential for 3D printed aluminum PCBs is being explored, which could revolutionize design and manufacturing processes.

Conclusion

Aluminum PCBs offer significant advantages in thermal management, durability, and performance in high-power applications. Understanding their principles of operation and appropriate applications is crucial for engineers and designers aiming to optimize their electronic devices. With ongoing advancements in materials and manufacturing technologies, aluminum PCBs are poised to play an increasingly important role in the future of electronics.

References

1. Zhang, Y., et al. (2018). "Thermal Management in High Power Electronic Applications." Journal of Electronics Cooling and Thermal Control*.

2. Johnson, M. (2020). "Aluminum PCBs: A Comprehensive Guide." Circuit World.

3. Chen, L., & Wang, H. (2019). "Comparison of Different PCB Materials in High Temperature Applications." International Journal of Electronics and Electrical Engineering.

4. Tao, Y. (2021). "Advances in PCB Manufacturing Technologies." Electronic Manufacturing Journal

5. Smith, R. (2022). "Innovative Applications of Aluminum PCBs in Automotive Electronics." Journal of Automotive Engineering

Industry Category