How to Understand Transparent PCB?

By:PCBBUY 12/31/2024 14:47

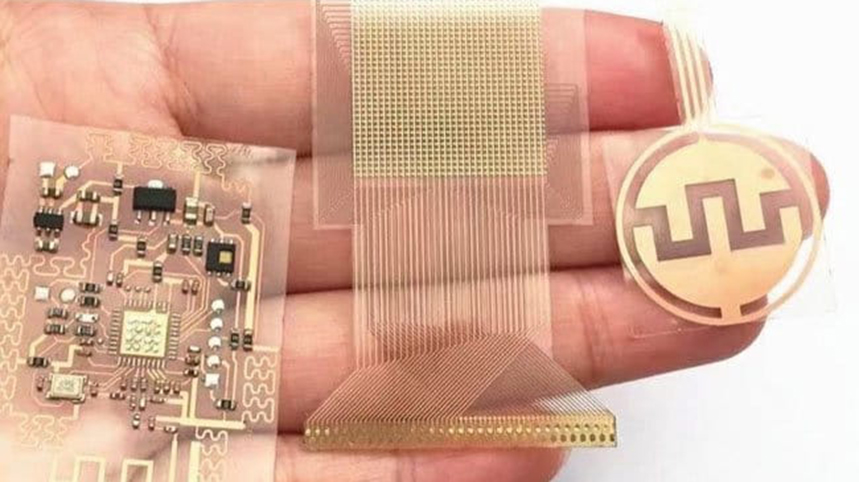

Transparent printed circuit boards (PCBs) represent a cutting-edge advancement in electronics design, combining functionality with aesthetics. These PCBs offer unique advantages for applications where visibility and space constraints are crucial. This article explores the world of transparent PCBs, covering their materials, manufacturing processes, applications, and challenges, along with professional insights and data-supported analysis.

What are Transparent PCBs?

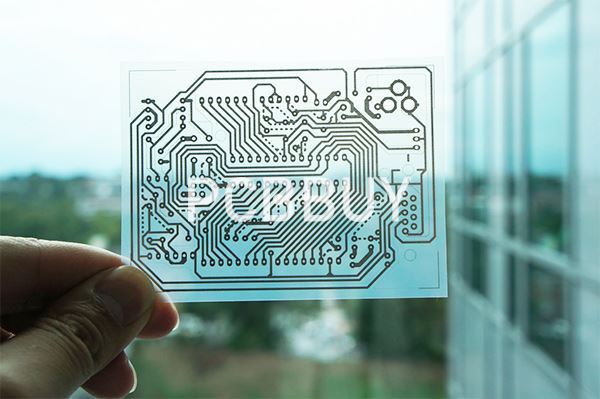

Transparent PCBs are a type of printed circuit board where some or all of the layers are made from transparent materials, allowing visibility through the board. Unlike traditional opaque PCBs made from materials like FR4, transparent PCBs utilize materials such as glass, transparent polymers, or flexible substrates that permit light transmission.

What Is the Importance and Applications?

The transparency of these PCBs opens up new possibilities in design aesthetics and functionality, making them ideal for applications in consumer electronics, automotive displays, wearable devices, and more. They are particularly valuable in applications where space-saving and visibility are critical, such as in heads-up displays or transparent screens.

What Are Materials Used in Transparent PCBs?

Glass Substrates

Glass is one of the primary materials used in transparent PCBs due to its excellent optical clarity, thermal stability, and electrical insulation properties. Glass substrates can support high-density circuitry and are often used in applications requiring both transparency and durability.

|

Material Property |

Glass PCB Substrates |

|

Transparency |

High (90%+ light transmission) |

|

Thermal Stability |

Excellent (high melting point) |

|

Electrical Insulation |

Excellent (high dielectric strength) |

Transparent Polymers

Transparent polymers such as polycarbonate, polymethyl methacrylate (PMMA), and transparent polyimides are also used. These materials offer flexibility and are lighter than glass, making them suitable for flexible and lightweight applications like wearable electronics.

|

Material |

Transparency |

Flexibility |

Thermal Resistance |

Applications |

|

Polycarbonate |

High |

Good |

Moderate |

Display panels, sensors |

|

PMMA |

High |

Low |

Low |

Optical components |

|

Transparent Polyimide |

Moderate |

High |

High |

Flexible electronics |

Transparent Conductors

The transparent conductors are crucial for creating circuits on transparent substrates. Common transparent conductors include indium tin oxide (ITO), conductive polymers, and silver nanowires. These materials combine electrical conductivity with optical transparency.

|

Conductor |

Transparency |

Conductivity |

Application Areas |

|

Indium Tin Oxide (ITO) |

High |

Moderate |

Touchscreens, OLEDs |

|

Conductive Polymers |

Moderate |

Variable |

Flexible electronics, sensors |

|

Silver Nanowires |

High |

High |

Transparent electrodes |

What Are Manufacturing Processes for Transparent PCBs?

Material Preparation

The manufacturing process begins with preparing the transparent substrate. Glass substrates are typically cut and polished, while polymer substrates may be cast or extruded into thin films.

Circuit Patterning

Photolithography

Photolithography is a common technique for patterning circuits on transparent substrates. It involves coating the substrate with a photoresist, exposing it to UV light through a mask, and then etching the exposed areas to create the desired circuit pattern.

|

Step |

Description |

|

Coating |

Apply photoresist to the substrate |

|

Exposure |

Expose to UV light through a mask |

|

Development |

Develop the photoresist to reveal the pattern |

|

Etching |

Remove the unwanted material |

Inkjet Printing

Inkjet printing is an alternative technique suitable for creating flexible circuits. Conductive inks containing nanoparticles of materials like silver or ITO are directly deposited onto the substrate to form circuits. This method is particularly useful for low-volume or custom designs.

Deposition of Conductive Layers

For transparent conductors, techniques such as sputtering or chemical vapor deposition (CVD) are used to deposit a thin conductive layer. These processes ensure uniform coverage and high transparency of the conductive materials.

Lamination and Assembly

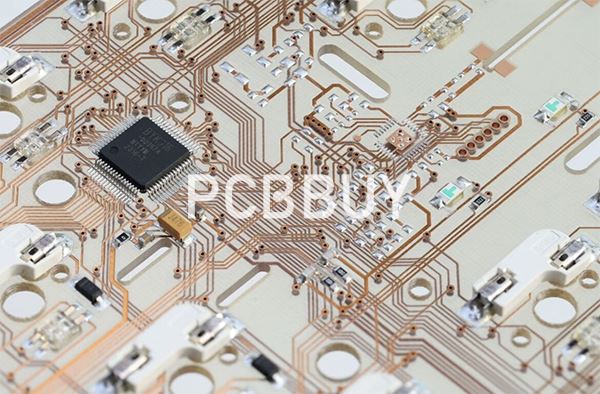

Once the circuit pattern is defined and the conductive layers are in place, the board may undergo lamination if multiple layers are required. Components are then assembled onto the board using traditional surface-mount technology (SMT) or through-hole methods.

What Are the Advantages of Transparent PCBs?

Aesthetic and Functional Benefits

Transparent PCBs offer a sleek and modern appearance, making them desirable for high-end consumer electronics and designer gadgets. The ability to see through the PCB allows for innovative product designs, such as transparent smartphones or wearable devices.

Space Efficiency

The use of transparent PCBs can reduce the need for separate display and circuit layers, allowing for more compact and integrated designs. This is particularly beneficial in applications like heads-up displays or augmented reality glasses, where space is limited.

Enhanced User Experience

Transparent PCBs enhance the user experience by allowing for better integration of touch-sensitive controls and interactive displays. They can also facilitate new forms of user interfaces that combine visual and tactile feedback.

What Are the Challenges in Transparent PCB Development?

Material Limitations

The selection of materials for transparent PCBs is limited compared to traditional PCBs. Transparent materials like glass and polymers often have lower mechanical strength, thermal stability, and electrical conductivity than their opaque counterparts.

Manufacturing Complexities

Manufacturing transparent PCBs involves specialized processes such as high-precision photolithography and sputtering, which can be costly and complex. Maintaining the optical clarity of the substrates while ensuring robust electrical connections poses additional challenges.

Cost Considerations

The materials and processes required for transparent PCBs are typically more expensive than those used for traditional PCBs. This cost factor can limit their use to high-end or niche applications.

What Are the Applications of Transparent PCBs?

Consumer Electronics

Transparent PCBs are increasingly used in consumer electronics, particularly in devices where aesthetics and compact design are critical. Examples include transparent smartphones, tablets, and wearable devices like smart glasses.

Automotive Industry

In the automotive industry, transparent PCBs are used in heads-up displays (HUDs) and other advanced driver-assistance systems (ADAS). These applications benefit from the integration of transparent circuitry with display technology, enhancing both functionality and design.

Medical Devices

The medical field leverages transparent PCBs for devices like flexible sensors, transparent electrodes for imaging systems, and wearable health monitors. The transparency and flexibility of these PCBs support innovative diagnostic and therapeutic applications.

Advanced Displays and Touchscreens

Transparent PCBs are integral to the development of advanced display technologies, including OLEDs, LCDs, and touchscreens. They enable the creation of thinner, lighter, and more flexible displays with integrated touch functionality.

What Are the Future Trends in Transparent PCB Technology?

Material Innovations

Ongoing research is focused on developing new transparent materials with improved electrical, mechanical, and optical properties. Materials such as graphene and other advanced nanomaterials are being explored for their potential to revolutionize transparent PCB technology.

Flexible and Stretchable Electronics

The demand for flexible and stretchable electronics is driving advancements in transparent PCB technology. Innovations in substrate materials and conductive inks are enabling the development of electronics that can bend, stretch, and conform to complex shapes.

Integration with Emerging Technologies

Transparent PCBs are expected to play a crucial role in the integration of emerging technologies such as augmented reality (AR), virtual reality (VR), and the Internet of Things (IoT). Their unique properties make them ideal for applications that require lightweight, flexible, and aesthetically pleasing electronic solutions.

Conclusion

Transparent PCBs represent a significant innovation in the field of electronics, offering unique advantages in design, functionality, and application. While there are challenges related to materials, manufacturing, and cost, ongoing research and development are paving the way for broader adoption and new applications. As technology advances, transparent PCBs are likely to become more prevalent in a wide range of industries, from consumer electronics to automotive and medical devices.

References

1. C. F. Coombs Jr., "Printed Circuits Handbook," 7th Edition, McGraw-Hill Education, 2016.

2. M. K. Thompson, "Introduction to Transparent Electronics," Elsevier, 2018.

3. T. Kim et al., "Flexible Transparent Conductive Films Based on Silver Nanowires," Advanced Functional Materials, vol. 23, no. 31, pp. 3896-3901, 2013.

4. IPC-2221, "Generic Standard on Printed Board Design," IPC, 2012.

5. S. M. Sze, "Physics of Semiconductor Devices," 3rd Edition, Wiley-Interscience, 2006.

Industry Category