How to Understand USB PCB Design?

By:PCBBUY 01/22/2025 15:14

USB (Universal Serial Bus) technology has become a cornerstone of modern electronics, enabling seamless communication and power delivery between devices. At the heart of this technology are USB PCB connectors, which facilitate the physical connection between the USB cable and the printed circuit board (PCB). This article provides an in-depth exploration of the various types of USB PCB connectors, including their technical specifications, applications, and the considerations for selecting the appropriate connector for a given application. The discussion is supported by data, equations, and tables, offering a comprehensive understanding of this critical component in electronic design.

Overview of USB Technology

The Universal Serial Bus (USB) standard was developed in the mid-1990s to standardize the connection between peripherals and computers. Since its inception, USB has undergone several revisions, each offering increased data transfer speeds and enhanced power delivery capabilities. Today, USB is ubiquitous, found in everything from computers and smart phones to industrial machinery and medical devices.

The Role of PCB Connectors

PCB connectors are essential components in electronic devices, enabling the transmission of signals and power between different parts of a system. USB PCB connectors, in particular, are critical for establishing a reliable connection between a USB cable and a device's PCB. The choice of USB connector type depends on several factors, including the application's power and data requirements, physical space constraints, and environmental conditions.

Classification of USB PCB Connectors

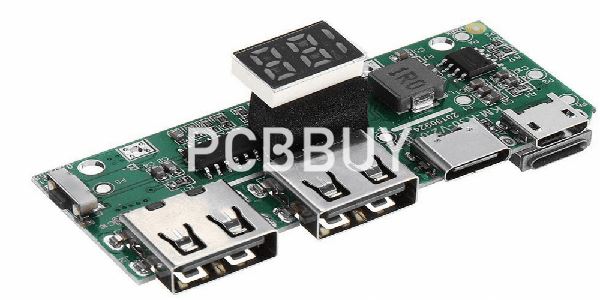

Overview of USB Type-A

USB Type-A is the original and most recognizable USB connector, characterized by its rectangular shape. It has been widely used since the introduction of USB 1.0 in 1996. Type-A connectors are typically found on host devices like computers, gaming consoles, and televisions.

Technical Specifications and Applications

Pin Configuration: USB Type-A connectors have four pins for USB 2.0 and nine pins for USB 3.0 and later versions. The additional pins in USB 3.0 and 3.1 allow for higher data transfer rates and enhanced power delivery.

Data Transfer Rates: USB 2.0 supports data transfer rates of up to 480 Mbps, while USB 3.0 and later versions support transfer rates up to 5 Gbps and beyond.

Power Delivery: USB Type-A connectors can deliver power ranging from 5V at 500mA (USB 2.0) to 20V at 5A (USB 3.1).

|

USB Version |

Max Data Rate |

Max Power Delivery |

|

USB 2.0 |

480 Mbps |

5V, 500mA |

|

USB 3.0 |

5 Gbps |

5V, 900mA |

|

USB 3.1 |

10 Gbps |

20V, 5A |

Common Use Cases

USB Type-A connectors are used in various applications, including:

Computers and Laptops: As the primary port for connecting peripherals like keyboards, mice, and external drives.

Consumer Electronics: Found in devices like smart TVs, gaming consoles, and media players.

Charging Devices: Used in power adapters and chargers for charging smartphones, tablets, and other gadgets.

USB Type-B Connectors

Explanation of USB Type-B

USB Type-B connectors have a more square shape and are often used for connecting peripheral devices to a host, such as printers, scanners, and external hard drives. Over time, the design has evolved to include variations like Mini-B and Micro-B, which are used in smaller devices.

Technical Specifications and Applications

Pin Configuration: Similar to Type-A, USB Type-B connectors have four pins in USB 2.0 and nine pins in USB 3.0 versions.

Data Transfer Rates: Type-B connectors support the same data transfer rates as their Type-A counterparts, with USB 3.0 and 3.1 providing higher speeds.

Power Delivery: The power capabilities of Type-B connectors are similar to those of Type-A, supporting higher power levels with the newer versions.

|

Connector Type |

Application |

Data Rate |

Power Delivery |

|

USB Type-B |

Printers, scanners, external drives |

Up to 10 Gbps |

20V, 5A |

|

Mini-B |

Digital cameras, older mobile devices |

Up to 480 Mbps |

5V, 500mA |

|

Mini-B |

Smartphones, tablets, portable drives |

Up to 5 Gbps |

5V, 900mA |

Design Variations

Mini USB Type-B: Smaller than the standard Type-B, used in older digital cameras and mobile devices.

Micro USB Type-B: Even smaller, commonly found in smartphones and portable drives.

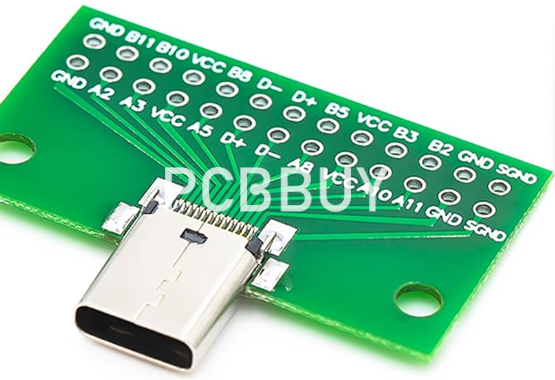

Introduction to USB Type-C

USB Type-C is the latest evolution in USB technology, designed to be a universal connector with a small, reversible design. It supports high-speed data transfer, significant power delivery, and is increasingly being adopted across a wide range of devices.

Technical Specifications and Applications

Reversibility: Unlike Type-A and Type-B, USB Type-C connectors can be inserted in any orientation, making them more user-friendly.

Data Transfer Rates: USB Type-C supports the latest USB standards, including USB 3.1, 3.2, and USB4, with data rates up to 40 Gbps.

Power Delivery: USB Type-C can deliver up to 100W of power (20V, 5A), making it suitable for charging laptops and powering other high-consumption devices.

|

USB Type-C |

Max Data Rate |

Max Power Delivery |

Common Devices |

|

USB 3.1 |

10 Gbps |

20V, 5A |

Smartphones, laptops, tablets |

|

USB 3.2 |

20 Gbps |

20V, 5A |

High-end peripherals, external SSDs |

|

USB 3.2 |

20 Gbps |

20V, 5A |

Docking stations, monitors, eGPUs |

Growing Adoption

The USB Type-C connector is becoming the standard for many devices due to its versatility and performance. It is now commonly found in:

Laptops and Tablets: As the primary charging and data port.

Smartphones: With many manufacturers transitioning from Micro USB to Type-C.

Peripheral Devices: Including external hard drives, monitors, and docking stations.

Micro USB Connectors

Characteristics of Micro USB Connectors

Micro USB connectors are smaller versions of USB connectors, designed for portable devices. They come in two primary types: Micro-A and Micro-B.

Technical Specifications and Applications

Micro-A: Features a rectangular shape, slightly smaller than Type-A.

Micro-B: Slightly trapezoidal, commonly used in smartphones and tablets.

Data Transfer Rates: Micro USB 2.0 supports up to 480 Mbps, while Micro USB 3.0 can reach 5 Gbps.

Power Delivery: Micro USB connectors typically deliver up to 2.5W, sufficient for charging small devices.

Transition to Type-C

As USB Type-C becomes more prevalent, Micro USB is gradually being phased out in favor of the newer standard. However, Micro USB is still widely used in many existing devices.

Mini USB Connectors

Overview of Mini USB Connectors

Mini USB connectors were commonly used in early mobile devices and cameras before the adoption of Micro USB. They are now considered somewhat obsolete but are still found in some older devices.

Technical Specifications and Applications

Data Transfer Rates: Mini USB 2.0 supports up to 480 Mbps.

Power Delivery: Similar to Micro USB, with lower power requirements suitable for small devices.

|

Connector Type |

Application |

Data Rate |

Power Delivery |

|

Mini USB |

Digital cameras, older mobile devices |

Up to 480 Mbps |

5V, 500mA |

USB 3.0 and 3.1

USB 3.0, with its distinctive blue connectors, brought a tenfold increase in speed to 5 Gbps, along with improved power management and backward compatibility with USB 2.0 devices. USB 3.1 further doubled the speed to 10 Gbps.

USB 3.2 and USB4

USB 3.2 introduced multi-lane operation, enabling data transfer rates of up to 20 Gbps. USB4, building on the USB Type-C interface, offers speeds up to 40 Gbps, along with enhanced power delivery and support for multiple data and display protocols.

Electrical Characteristics

USB connectors are designed to carry both power and data, with electrical characteristics that vary based on the connector type and USB version.

Current Ratings and Voltage

Current: The current rating of a USB connector determines the maximum amount of current it can safely carry. For example, USB 2.0 connectors are rated for 500mA, while USB 3.0 connectors can handle up to 900mA.

Voltage: Standard USB connectors operate at 5V, but newer versions like USB Power Delivery (USB PD) allow for variable voltage levels up to 20V.

Power Delivery (PD) Calculations

Power delivery in USB connectors can be calculated using the formula:

P = V X I

Where:

P = Power (W)

V = Voltage (V)

I = Current (A)

For example, a USB Type-C connector delivering 20V at 5A provides:

P = 20V X 5A = 100W

Technical Table

|

USB Version |

Max Current |

Max Voltage |

Max Power |

|

USB 2.0 |

500mA |

5V |

2.5W |

|

USB 3.0 |

900mA |

5V |

4.5W |

|

USB PD |

5A |

V |

100W |

Mechanical Design and Durability

Material Considerations

The materials used in USB connectors play a crucial role in their durability and performance. Common materials include:

Contact Pins: Typically made of copper alloy, often plated with gold to prevent corrosion and ensure good conductivity.

Housing: Usually made of high-temperature plastic or metal, providing mechanical strength and protection.

Connector Durability and Life Cycle

USB connectors are designed to withstand a certain number of insertion and removal cycles, which vary depending on the type:

USB Type-A and Type-B: Typically rated for 1,500 cycles.

Micro USB: Rated for 10,000 cycles.

USB Type-C: Rated for 10,000 cycles, with some designs offering up to 20,000 cycles.

Data Table on Connector Life Cycles

|

Connector Type |

Life Cycle Rating |

|

USB Type-A |

1,500 cycles |

|

USB Type-B |

1,500 cycles |

|

Micro USB |

1,500 cycles |

|

USB Type-C |

10,000 - 20,000 cycles |

Applications and Industry Use Cases

Consumer Electronics

USB connectors are integral to consumer electronics, providing both data transfer and power delivery capabilities.

Case Study: USB Type-C in Smart phones

The transition from Micro USB to USB Type-C in smart phones has led to faster charging times, higher data transfer speeds, and the ability to connect a wider range of peripherals.

Industrial and Medical Devices

In industrial and medical settings, USB connectors are used in environments where reliability and durability are critical.

Example: USB in Medical Equipment

USB connectors in medical devices must meet stringent standards for electromagnetic compatibility (EMC) and must be able to withstand repeated sterilization processes.

Automotive Applications

The automotive industry has increasingly adopted USB connectors for infotainment systems, charging ports, and diagnostic tools.

USB in Electric Vehicles (EVs)

In electric vehicles, USB connectors are used for charging, data transfer, and as interfaces for various sensors and control systems.

Industry Category