How to Understand the Process and Benefits of ENEPIG Surface Finish in PCB?

By:PCBBUY 10/30/2024 16:38

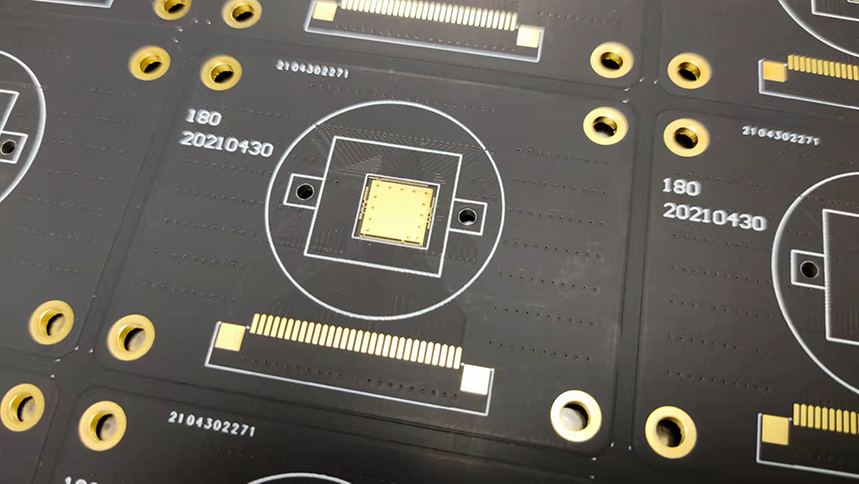

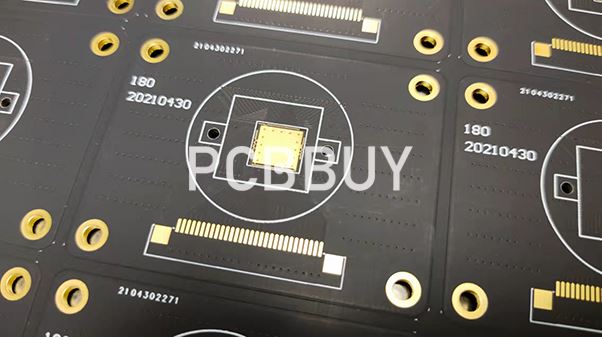

As the demand for high-performance electronic devices continues to rise, the printed circuit board (PCB) industry is constantly evolving to meet the needs of modern applications. One significant aspect of PCB manufacturing is the surface finish used to protect and enhance the solderability of the copper pads. Among various surface finishes, Electroless Nickel Immersion Gold (ENEPIG) has gained popularity due to its unique properties and benefits. This article explores the ENEPIG surface finish in detail, examining its chemical composition, application process, advantages, and comparison with other finishes.

What is ENEPIG?

ENEPIG stands for Electroless Nickel Electroless Palladium Immersion Gold. It is a multi-layer surface finish that combines the benefits of nickel, palladium, and gold to provide an ideal solderable surface for PCBs. The three layers include:

1. Electroless Nickel (EN): A layer of nickel deposited on the copper surface to provide corrosion resistance and serve as a barrier layer.

2. Electroless Palladium (EP): A thin layer of palladium that enhances the solderability and provides additional protection against oxidation.

3. Immersion Gold (IG): A gold layer that offers excellent solderability and protects the underlying layers from oxidation.

What Is the Chemical Process of ENEPIG?

The ENEPIG process involves several key steps, each critical to achieving the desired surface finish. The chemical equations governing these processes are as follows:

1. Electroless Nickel Deposition

Electroless nickel is deposited using a chemical reduction process. The primary chemical reaction can be described as:

Ni2++H2PO2-+ H2O→Ni +H2PO3- + H+

In this reaction, nickel ions are reduced and deposited on the PCB surface, forming a layer approximately 3-5 microns thick.

2. Electroless Palladium Deposition

The palladium layer is also deposited via an electroless process, typically using palladium chloride as the source:

Pd2+ + H2 PO2- + H2 O→Pd +H2PO3- + H+

The thickness of the palladium layer is usually around 0.1-0.3 microns, sufficient to enhance solderability.

3. Immersion Gold Deposition

The immersion gold process involves immersing the nickel-palladium layer in a gold solution. The following reaction occurs:

Au3+ +Ni→Ni2+ + Au

This reaction deposits a thin layer of gold (approximately 0.05-0.15 microns) on top of the palladium.

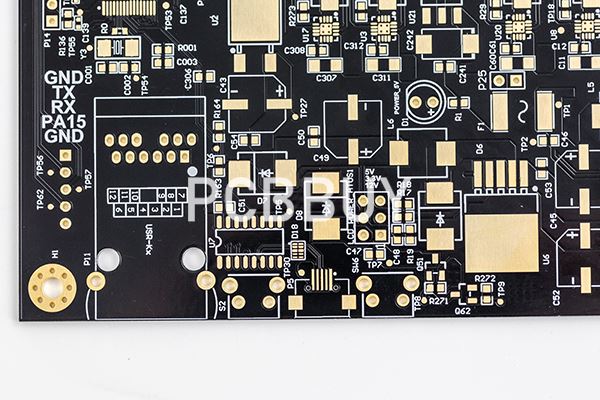

What Are the Advantages of ENEPIG?

1. Excellent Solderability

ENEPIG provides superior solderability compared to other surface finishes due to the presence of gold and palladium, both known for their excellent wetting properties.

2. Corrosion Resistance

The nickel layer serves as a barrier against corrosion, protecting the underlying copper from environmental factors that could lead to degradation.

3. Compatibility with Lead-Free Solders

ENEPIG is compatible with lead-free soldering processes, making it suitable for modern electronics that adhere to environmental regulations.

4. Reduced Risk of Black Pad Phenomenon

The multi-layer structure of ENEPIG reduces the risk of black pad defects, which can occur with traditional nickel-gold finishes.

5. Shelf Life

ENEPIG surfaces have an extended shelf life compared to other finishes, allowing for longer storage times before assembly.

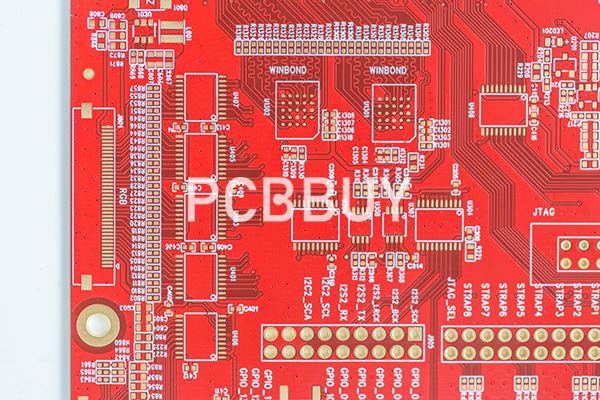

What Are Comparison with Other Surface Finishes?

To understand the benefits of ENEPIG better, we can compare it with other common surface finishes used in PCB manufacturing, such as HASL (Hot Air Solder Leveling) and OSP (Organic Solderability Preservative).

|

Surface Finish |

Solderability |

Corrosion Resistance |

Shelf Life |

Cost |

|

ENEPIG |

Excellent |

Good |

Long |

Moderate |

|

HASL |

Good |

Moderate |

Shor |

Low |

|

OSP |

Moderate |

Good |

Moderate |

Low |

What Are Applications of ENEPIG in PCB Manufacturing?

ENEPIG is widely used in various applications, particularly where reliability and performance are critical. Some common areas include:

1. Consumer Electronics: Smartphones, tablets, and other devices that require high-density interconnections benefit from the superior solderability of ENEPIG.

2. Automotive Electronics: The automotive industry demands reliable connections, making ENEPIG an ideal choice for components subjected to harsh environments.

3. Medical Devices: ENEPIG's corrosion resistance and reliability are crucial for medical devices that require long-term stability.

Conclusion

The ENEPIG surface finish presents a reliable solution for PCB manufacturers seeking to enhance the performance and longevity of their products. With its unique combination of electroless nickel, palladium, and immersion gold, ENEPIG offers excellent solderability, corrosion resistance, and compatibility with lead-free soldering processes. As the demand for high-quality electronics continues to rise, understanding and implementing ENEPIG will be vital for staying competitive in the PCB industry.

References

1. P. H. F. R. H., & G. A. H. (2019). *Electroless Nickel Immersion Gold: A Review of the Surface Finish Technology in PCB Manufacturing*. Journal of Electronics Materials, 48(4), 1120-1133.

2. J. A. M. (2020). *Surface Finishes for PCB: An Overview of ENEPIG, HASL, and OSP Technologies*. IEEE Transactions on Electronics Packaging Manufacturing, 43(2), 151-162.

3. Z. X., & L. Y. (2018). *The Effect of ENEPIG on the Solderability and Reliability of PCB Assemblies*. Surface and Coatings Technology, 353, 327-335.

Industry Category