How to calculate PCB assembly cost?

By:PCBBUY 07/27/2021 17:08

During the PCB manufacturing process, how to calculate PCB assembly cost?In this passage, we will focus on the methods of PCB assembly cost calculating. please check and read the content we prepare for you to learn more information.

What is the material cost before assembly?

According to the customer's BOM list, the purchasing department of the processing firm will make an inquiry, including PCB bare board, electronic parts, etc. Sometimes, PCB assembly costs and engineering costs will be included in purchasing quotation. It needs to cover about 5% of the material loss when purchasing the components, due to the reason of material loss, like resistance and capacitance disk loading material and SMT chip. For the small batch of PCBA, engineering costs are usually covered in quotation, including the costs of processing file, stencil, Changing SMT line etc.

Solder Joint Cost Counting

PCB assembly costs include SMT and DIP after welding, etc. which is accounted separately according to the specific of printed circuit board solder joints and the processing ways. Generally, a solder pad is counted as 1 point and solders joints of IC accounted by the number of feet. Above 1206 SMD precision of solder pad is counted in accordance with a solder pad to 2 points, except CD54 inductance counting to 12 points, other larger inductance counted as 24 points. In addition, plug spacing with 3.96 of one solder pad as 2 solder points. After counting all solder joints, its costs are counted among 0.008~0.03 CNY on the basis of solder joints.

We also need to count the PCBA test costs according to each PCBA board test time; In terms of packaging logistics, special packaging materials as well as the need to count the cost of three-proofing paint, in addition, according to customers’ transaction terms such as FOB, it needs extra counting of customs logistics costs.

What is PCB assembly cost breakdown?

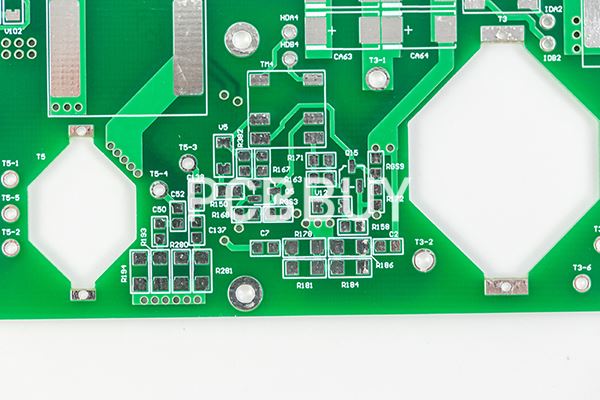

1. PCB Board Size and Number Layers

The bigger the PCB board, the more the assembly cost would be. So we need to better utilized the board the save money. And a higher number of cooper layers would also raise the PCB production cost, so complex PCB design would definitely require more layers assembilies which need more cost.

2. PCB Board and Component Material

If you are cooperating with electronic contract manufacturers like us, you can tell us if you agree on using alternate brands of PCB materials with similar traits, so that we can use the PCB materials in stock instead of buying the specific assembly materials.

3. PCB Board Design Complexity

We always need to try our best to minimize the complexity of our PCB layout, because extra work on the PCB board would always raise the cost. So we need to fulfill our purpose and reduce the PCB layout complexity as possbile as we can.

4. PCB Assembly Order Volume

Larger quantities result in lower PCB assembly costs due to encomies of scale. So we would prefer high volume of PCB order so that we can save our time on setting it up. Most companies would offer you a good discount if the PCB order volume is big enough. So if you need 10,000 PCB assemblies in one year, it's best to order them for one time instead of separate for mulitple times which would cost you more money.

5. PCB Assembly Lead Time

Whenever you ask us what's the cost of the PCB assembly, the first question from us is what your expected lead time is. As we all know: Time is Gold. So a quicker turnaround time means the higher cost. Since the PCB manufacturers need to invest more resources to meet your requirements.

How to reduce the PCB assembly cost?

Solder Paste Printing

SMT assembly starts from solder paste printing that aims to place a proper amount of solder paste onto pad on which components will be soldered. The quality of solder paste printing is mainly determined by three elements: solder paste condition, scraping angle and scraping speed.

High quality can never be obtained by SMT assembled PCBs unless solder paste is properly stored and applied. Solder paste has to be stored in a fridge to be kept in a low temperature and its temperature should be recovered to room temperature prior to its application on SMT manufacturing line.

Solder Paste Inspection (SPI)

Solder paste inspection in itself is an optional way to reduce cost because it’s better to reduce solder defects right now than to catch them later. SPI is not a must-be step in SMT assembly procedure but with it applied it’s beneficial to decrease your manufacturing cost and to improve the quality of products.

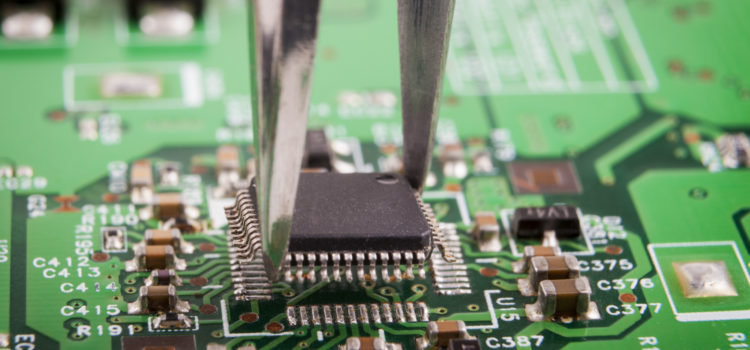

Chip Mounting

Chip mounting plays a core role in SMT assembly process. Chip mounting is completed by chip mounters that differ from each other primarily in terms of speed and mounting capability. Some small components are normally placed by high-speed chip mounters that are capable of placing them quickly to make those components quickly adhered to the solder paste on pad.

Reflow Soldering

In the process of reflow soldering, solder paste is melted to generate IMC (Intermetallic Compound) to connect component pins and board. The temperature profile followed in the process of reflow soldering process covers preheating, temperature rise, reflow and cooling.

Industry Category