How to choose the right solder?

By:PCBBUY 07/16/2021 17:24

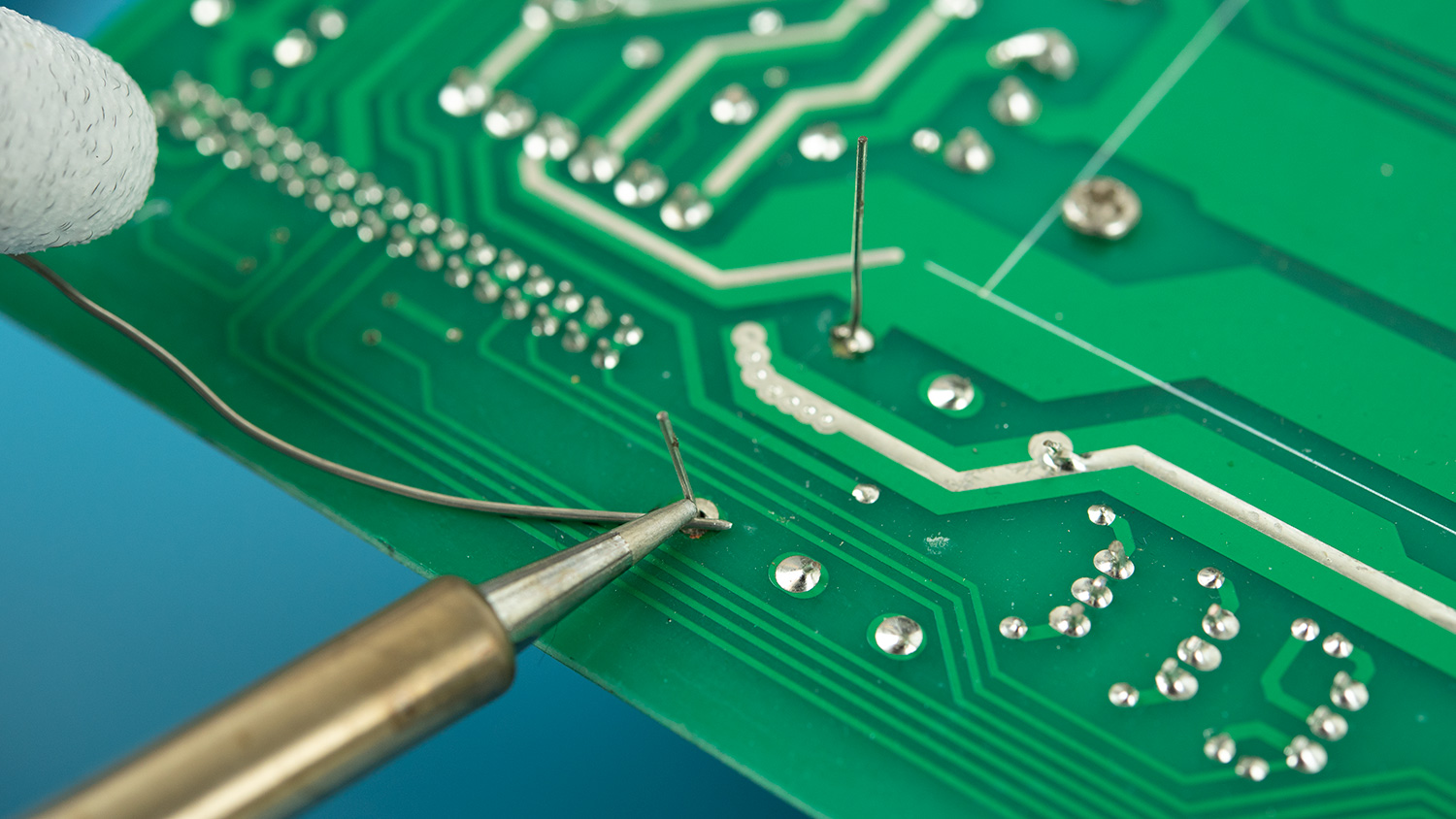

There are so many types of solder during the PCB manufacturing process, and do you know how to choose the best solder for PCB? It will affect the performance and quality of the finished boards. If you are looking for the best solder for circuit boards, check the content below for more professional knowledge.

Which one is better? - Lead or lead-free solders

There exist hundreds of permutations and combinations of a solder. These can be of different wire sizes, alloys, and flux types. These factors can drastically impact your soldering experience. The solder on a circuit is like connective tissue. It is the glue that sticks components to substrates. Solders are also providing some much-needed continuity to a circuit board.

For years, lead solders have been the go-to solders in the electronic industry. However, lead causes many health and environment-related issues. These issues further gave rise to lead-free solders.

Lead solders consist of a mixture of lead and tin. Lead solders heat up at a much lower temperature than lead-free solders. Due to this, the thermal threat to the component decreases. Therefore, lead-free solders consume less energy and time too. Also, the solder develops a shinier appearance when compared to the lead-free solder.

Lead-based solders are Cheaper than the lead -free ones. However, the distance between the lead-based and lead-free solder is ever decreasing. Thus one can also go with the lead-free solder for the environment's sake. As of now, the most used type of solder is the lead-free rosin core solder. It usually consists of tin or copper alloy. But due to the environment and health issues, it has started to lose popularity.

Based on Chemical Contents of Solder

There are various kinds of solders available in the market. These also include substances like silver and bismuth. Using these materials enables you to personalize the solder based upon your requirements. There are only three primary categories of solders to which you can narrow your search.

Lead solders were, for a long time, the go-to substance in the electronics industry. They have a melting point of around 180-190°C. The most commonly existing blend is the 60/40 (tin/lead) blend. Tin helps maintain a lower melting point. On the other hand, lead represses the growth of tin whiskers. The better concentration of tin also ensures better shear and tensile strength.

Lead-free solders have started gaining popularity. The primary reason is the fact that the EU restricted the use of lead in electronics. In countries like the US, manufacturers receive tax relief for using lead-free solders. Lead-free solders can, however, sometimes cause the formation of tin whiskers. However, the use of conformal coatings can control these tin whiskers. Another alternative is to incorporate substances like nickel and silver for layers.

Flux core solder, sold as a single reel, consists of a reducing agent at the core. During the process of soldering, the flux gets released. This flux reduces the metal at the point of contact, which results in a cleaner and neater connection. In electronics, rosin is usually a flux.

What is the cost of solders?

Lead base solders are cheaper than lead-free solders. However, one can use silver, bismuth, and other compounds to get desired properties. Silver coated solders are expensive but provide more strength than tin. Bismuth based solders are also costly. It is primarily due to their ability to operate at low temperatures.

How to choose a solder based upon your electronic product?

Another factor to keep in mind is the nature of electronic products and their attributes. Using dissimilar metals can cause corrosion. An ideal solder consists of a specific mixture of elements that give the desired results. For instance, the lead solder melts in a particular range of 180°C - 190°C. However, a eutectic blend of Sn63Pb37 melts at exactly 183°C. 70Pb30 works well with gold contacts (less gold leaching). 70Pb30 also provides high resistance to fatigue during thermal cycling. Therefore, you can choose a custom solder based on the properties you desire. While choosing, keep in mind factors like thermal resistance, corrosion resistance.

What is the perfect solder diameter for you?

The gauge number determines the diameter of the solder. A gauge number is a unit of thickness for metal sheets and wires. For amateur and hobbyists, gauge numbers 18, 20, and 21 are the numbers that work well. The diameters of these numbers are 1.22, 0.914, and 0.813 mm, respectively. Staying in this range is a good idea for amateurs and beginners. Using wires of this diameter reduces solder wastage.

· For Plastic Dual In-line Package (PDIP) with a pin spacing of 0.1-inch, gauge 18 (1.22mm) is ideal.

· 22-gauge numbered wires are suitable for smaller PCBs. Cables with gauge numbers 22 have a diameter of 0.711 mm. Pins are much closer in SMD and SOIC packages, making this wire ideal due to their small diameter.

· Pin spacing in old circuits is much more than the current channels. These circuits have more significant solder tags. Gauge 16, owing to their larger diameter of 1.63mm, are the perfect choice for old courses.

Industry Category