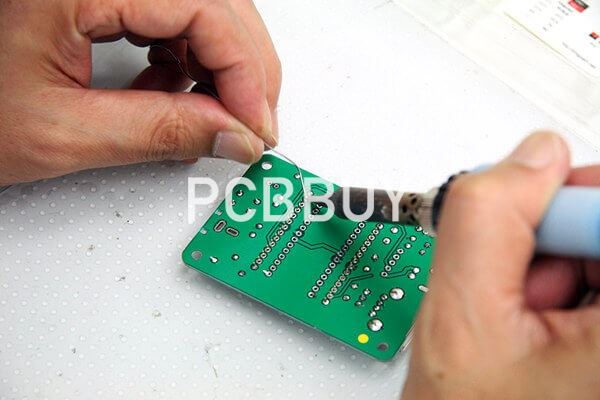

How to do SMT soldering?

By:PCBBUY 08/06/2021 17:25

In the practical manufacturing, soldering defects usually take place. the soldering issues seen in this stage aren't completely caused by reflow technology because SMT soldering quality is closely correlated with manufacturability of PCB pad. How to do SMT soldering?Check and read the content we prepare below for more knowledge.

What is preparation of BOM?

As one of the most important composites in SMT, the quality and performance of BOM is directly correlated the quality of reflow soldering. Specifically, the following aspects have to be taken into consideration:

a. Component packaging has to meet the automatic mounting requirement of mounter.

b. Component figure has to meet the requirement of automatic SMT in that it has to have standard shape with high dimension accuracy.

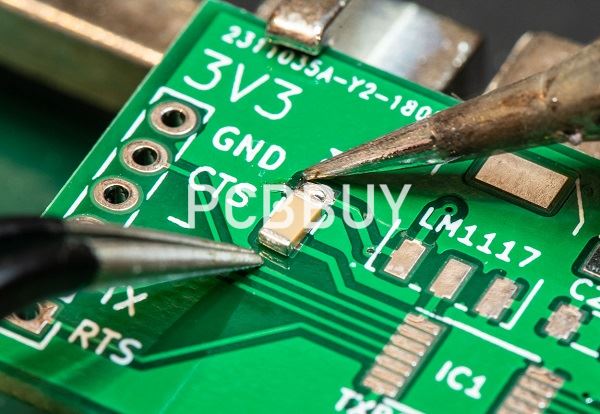

c. Solderable ends of components and PCB pad soldering quality should meet the requirement of reflow soldering and solderable ends of components and pad are not polluted or oxidized. If solderable ends of components and PCB pad suffer from oxidation, pollution or damp, some soldering defects will possibly take place such as bad wetting, pseudo soldering, solder beads or cavity. This is especially true for humidity sensor and PCB administration. Humidity sensors have to be stored in drying cabinet after vacuum packaging and it's necessary to roast them prior to manufacturing next time.

What are the essential factors in SMT soldering?

Solder Paste Printing technology primarily aims to solve problems concerning incompatibility of solder paste printing amount (filling amount and transferring amount of solder paste). Based on professional statistics, with PCBs correctly designed, 60% of PCBs for rework are caused as a result of bad solder paste printing. In solder paste printing, three important "S"s must be remembered: solder paste, stencil and scraper. If correct selections are made, excellent printing effect can be obtained.

Quality of solder paste

As a necessary material for reflow soldering, solder paste is a kind of paste solder evenly mixed by alloy powder and paste flux (rosin, diluents, stabilizer etc.) among which alloy powder is the key element to composition of solder joints. Flux is the critical material to eliminate surface oxidation, increase wettability and ensure quality of solder paste. In terms of quality, generally speaking, 80% to 90% of solder paste belongs to metal alloy while it accounts for 50% in terms of volume. Solder paste quality insurance comes primarily in two aspects: storage and application. Solder paste is usually stored between 0 and 10°C or stored according to requirement of manufacturers.

Stencil design

The key function of stencil lies in uniform solder paste coating on PCB pad. Stencil is a must-be in printing technology and its quality directly influences quality of solder paste printing. Up to now, there are three methods to manufacture stencils: chemical corrosion, laser cutting and galvanoformung. Stencil design won't be ensured until the following aspects are fully considered and suitably dealt with.

Scraper

Scrapers, to some extent, make a difference to printing quality based on their different hardness material and shapes. Generally, steel scrapers with nickel plating are used and scrapers with 60° are ordinarily applied. If there are through-hole components, scrapers with 45° are advised so that tin amount on through-hole components can be increased.

Printing parameters

Printing parameters mainly encompass scraper speed, scraper pressure, stencil down-release speed, stencil cleaning mode and frequency. Restrictive relationship does occurs between angle of scraper and stencil and viscosity of solder paste, so printing quality of solder paste won't be ensured until these parameters are correctly controlled. Generally speaking, a low speed of scraper leads to relatively high printing quality with possibility of vague shape of solder paste. Furthermore, an extremely low speed even decreases manufacturing efficiency. On the contrary, s high speed of scraper will possibly lead to insufficient solder paste filling in net hole. Too much scraper pressure may lead to insufficient tin and increasing abrasion between scraper and stencil while extremely low pressure leads to incomplete solder paste printing.

Equipment accuracy

During printing products with high density and small space, printing accuracy and repeated printing accuracy will affect stability of solder paste printing.

PCB support

PCB support is an important adjustment content for solder paste printing. If PCB lacks effective support or features an unsuitable support, high thickness of solder paste or uneven solder paste. PCB support should be arranged flat and uniform in order to guarantee closeness between stencil and PCB.

Industry Category