How to identify PCB manufacturer?

By:PCBBUY 06/07/2021 18:00

If you are going to order PCB products, it is pretty important for you to find a reliable PCB manufacturer to produce the boards you want. And a professional manufacturer will determine the quality and performance of the finished PCB. Please check and read the content we provide to learn more knowledge about it.

What are the tips before choosing PCB manufacturer?

When choosing a manufacturer, you should have some questions prepared. You can get the answers to these questions through your own research using the company’s website and other online resources such as online reviews. You can also get the answers by asking the company directly.

Getting the answers to these questions will help you determine whether a given PCB manufacturer is the best one for the job.

1. How long have you been doing this?

Experience is crucial in PCB manufacturing. It provides insight into the amount of knowledge and resources a manufacturer may have, their competence and how well they’ve been able to adapt over time to changes in the industry.

2. What certifications do you have?

Certifications provide additional insight into how qualified a manufacturer is. To receive certification, a third party typically needs to verify that the company complies with a standard or other requirement. The International Organization for Standardization (ISO) publishes standards related to quality management, such as ISO 9001, as well as other areas. IPC produces standards that are specific to the PCB and electronics manufacturing industries.

Make sure that each manufacturer you’re considering working with is capable of complying with all of the standards that apply to your industry and products. This, of course, includes broad regulations and standards such as restriction of hazardous substances (RoHS) but also includes requirements that relate to your industry in particular. This is one area in which working with a company that has experience with your industry is valuable.

3. What makes your company unique?

This question can help you make your final decision once you’ve found several similar manufacturers that provide the products and services you need. To answer this question, you can explore the value-added services each manufacturer offers and even just ask a company representative what they believe sets their organization apart.

How to identify PCB manufacturer?

It can be difficult to narrow down your PCB manufacturer choices, since there are so many options and, at first glance, many companies seem to be quite similar. Some topics you should investigate early in your search include a company’s products, services, capabilities and facilities.

1. Products

Get information about what types of PCBs each manufacturer offers. This may include rigid, flexible and rigid-flex boards as well as metal core, aluminum-backed and hybrid boards. Additionally, ask about the substrates the companies use for their boards. Aluminum boards, for example, offer high thermal conductivity and excellent electrical insulation, while heavy copper boards are ideal for high current applications.

Product Quality

You’ll also want to explore the quality of the boards each manufacturer provides and the quality control processes they have in place. Some quality control measures to look for include:

Price

Price is another factor that is always essential to consider. Of course, you want to minimize your costs, but you must also be careful that the quality of your boards remains sufficient. You need to find a manufacturer that provides products that meet your quality standards while remaining in your price range.

One aspect of cost to consider is the initial quote. Once you provide a manufacturer with information about your project, they can provide you with a quote. To ensure the quote they give you is an actual estimate of the total cost, ask if there will be any other fees added later in the order process.

Additionally, ask about potential discounts for bulk orders or frequent orders. Some manufacturers will offer discounts or special arrangements for return customers. Ask whether these opportunities exist to ensure you’re getting the best possible price.

2. Services

You’ll also need to determine which services each manufacturer offers and make sure they can provide the ones you need. Working with companies that provide numerous services comes with the advantage of not having to switch between companies throughout the production process. Sometimes, though, you might want a more specialized company. Beyond assembly, here are some of the services to look for:

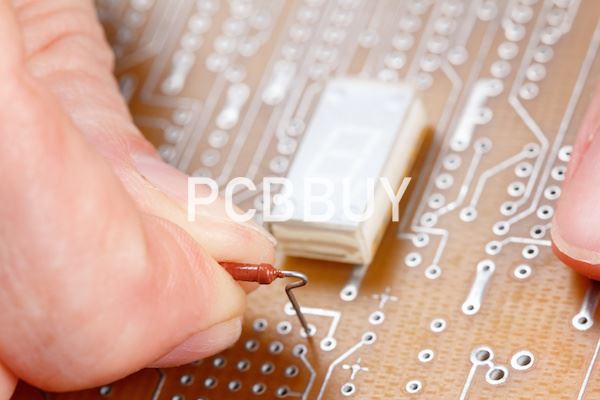

Prototyping

Creating a prototype PCB before going to production can reduce the total timeframe and costs of your production process. Creating prototypes gives you sample boards you can use to test your design and then fix problems and make improvements, which is much more cost-effective to do earlier in the production process.

Layout and design services

Layout and design services can help you to speed up your production process. Some companies will do a complete design for you after you give them basic information about what you need. You may be able to send in existing files and have a company make changes or help you solve a design problem.

File review and analysis

Some PCB manufacturers will provide a review and analysis of your design before they manufacture. This serves as a final check for design errors and defects and helps ensure that the manufacturer has all of the necessary files and information before beginning manufacturing, helping to avoid delays after you place your order.

SMT stencil production

SMT stencils, which are made of stainless steel foil and are laser cut, help to ensure that the solder paste is printed in the correct places on the PCB. Using a stencil to apply solder paste is much more accurate than applying it by hand.

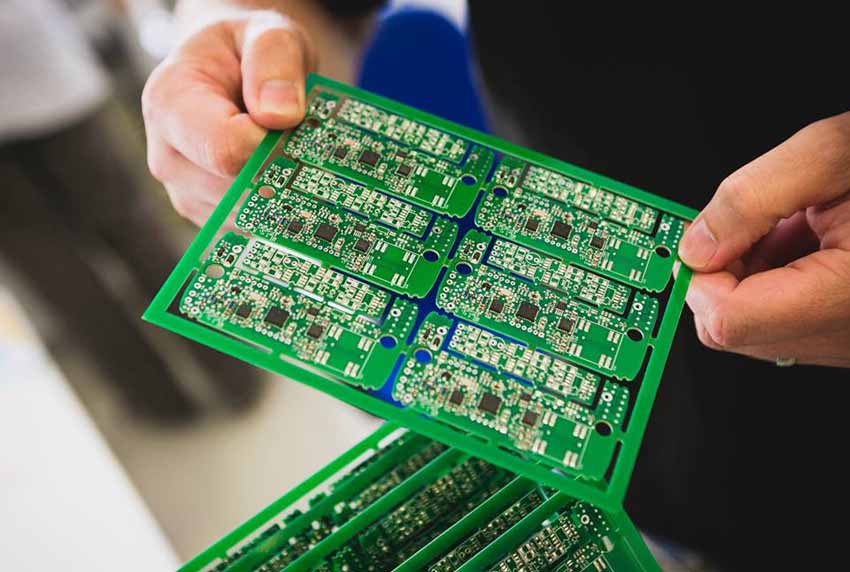

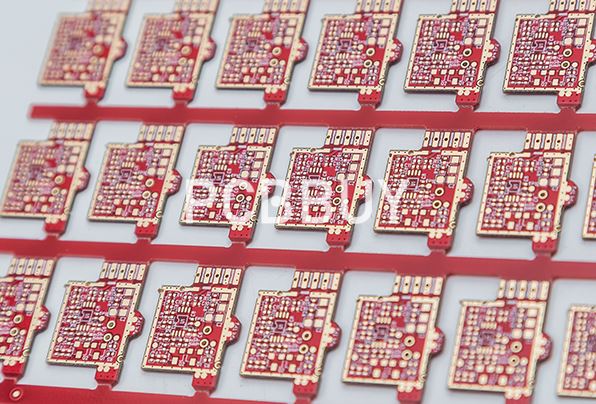

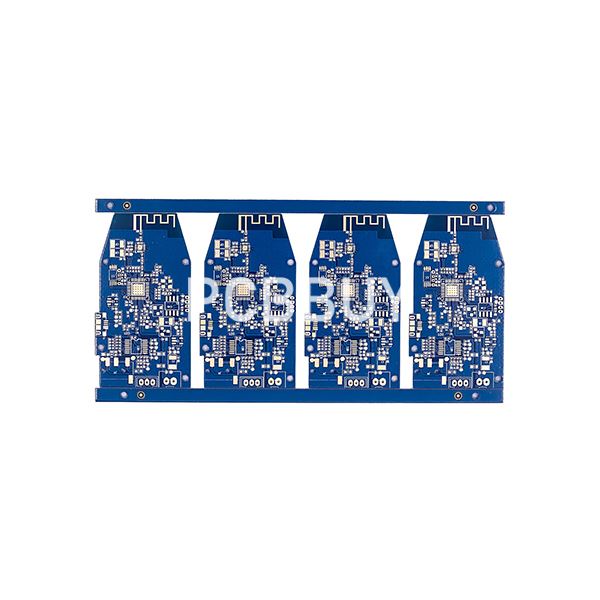

Panelization

Panelization refers to grouping boards to enable faster processing and is typically used for high-volume production. If you plan on placing high-volume orders, you may want to look for a manufacturer that provides panelization while still allowing for any customization you may need. This can significantly decrease your timeframe for production.

3. Capabilities

You will also need to make sure that the company in question has the capabilities necessary for providing the PCB solutions you need. Gather information about the following capabilities.

Order quantity

What are the maximum and minimum order sizes that each manufacturer can fill within your required timeframe?

Lead time

You’ll want to get information on each company’s lead time for prototypes, small volume, medium volume and high volume orders. Ensure that the company’s estimated delivery time for the type of order you’ll be placing is compatible with your requirements. Additionally, check whether the company provides a quick turnaround service for rush orders. Some manufacturers offer an order tracking service, which enables you to easily the status of your order and when you can expect it to arrive.

Number of layers

Consider whether a manufacturer can provide bare, single-layer, double-layer and multi-layer boards as well as how many layers they can accommodate. The number of layers likely varies for flexible, flex-rigid and rigid boards, so make sure you get the details for the types of boards you plan on ordering.

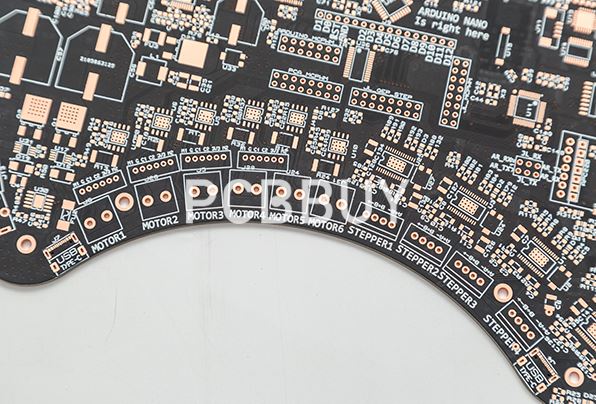

Surface finish options

PCB surface finishes protect the copper surface of boards from corrosion and provide other advantages, such as making soldering easier. There are a variety of possible surface finish options available, and different PCB manufacturers may offer different ones. Possible surface finishes include electroless nickel immersion gold (ENIG), immersion silver, immersion tin, hot air solder leveling (HASL), organic solderability preservative (OSP) and hard gold.

Via options

What types of vias can each manufacturer provide? Ensure that each manufacturer can provide the kinds of vias you need, whether that’s copper-filled vias, blind vias, buried vias or micro vias.

Controlled impedance modeling

For boards that operate in high frequency ranges, you may need controlled impedance. If you need repeatable high-frequency performance, check that manufacturers offer controlled impedance modeling and have knowledge in trace impedance.

Specs and tolerances

What kinds of tolerances can each manufacturer manufacture to, and do they meet your requirements? One critical spec to check is the drill aspect ratio, which refers to the ratio of the PCB’s thickness to the drilled hole’s diameter and relates to the ability to provide copper plated holes using chemical processes. As the aspect ratio increases — that is, as the holes get smaller — achieving reliable plating becomes more difficult. Other important specs include outer layer trace and space, inner layer trace and space, minimum drilled hole, standard drilled hole, minimum pad size, minimum feature to edge and minimum core thickness.

Industry Category