PCB Stack up Analysis:How to make 4-layer PCB?

By:PCBBUY 09/11/2021 10:29

You may know the design basics to look out for in PCB multilayer stackup, it’s important to know the types of stackup available and how to choose the right stackup design for your needs. There are five types of PCB layer stackup: 2-layer, 4-layer, 6-layer, 8-layer. How many layers you need is primarily determined by the size of the circuit, the size of the board and the requirements for the board.

In this passage, we will introduce you the capability of 4-layer PCB, including the PCB stackup. If you are interested in methods of make 4-layer PCB, check and read the content we prepare for more information.

What are the PCB stackup capabilities?

A PCB stackup refers to the arrangement of copper and insulating layers that make up a PCB. These layers are arranged in a way to get multiple printed circuit boards on the same device. At their most basic, multilayer PCBs consist of at least three conductive layers. The bottom layer is synthesized with the insulation board, and each circuit board layer is connected to the next.

While PCB layering creates a more complex and space-saving board, PCB stackups also offer the following advantages:

· Maximize functionality: Multilayer PCBs can multiply the speed and functionality in the device, making for a more functional board.

· Minimize vulnerability: Layer stacks can help protect internal layers from external noise, making it less vulnerable to damaging exterior forces.

· Reduce radiation: Well-designed PCB layer stacks can help you minimize radiation from your device, especially in high-speed layouts. It is important to note, however, that poor designs with impedance mismatches can easily result in greater EMI radiation than a normal PCB.

· Decrease costs: Good layer PCB stack-ups can also help achieve lower-cost manufacturing by placing multiple circuits onto a single board. One board means streamlined manufacturing for the board, the part the board will be used in and the packaging for the complete setup.

What is the importance of PCB stackup?

There are three or more conductive layers in one multilayer PCB with two layers outside and one layer synthesized in the insulation board. With the increase of PCB complexities and densities, it's possible for some issues to take place such as noise, stray capacitance and cross talk when layer arrangement gets inefficient design.

Planning optimal multilayer stack-up is one of the most important elements in determining the Electromagnetic Compatibility (EMC) performance of a product. A well-designed layer stack-up can both minimize the radiation and can stop circuit from being interfered by external noise sources. Well-stacked PCB substrates can also reduce signal cross talk and impedance mismatch issues.

How to make 4-layer PCB?

Challenges

Most of the BGAs would have a ball pitch between 0.5 mm to 1.0 mm. As the BGA package is usually meant for FPGA and microcontrollers, the number of pins underneath the IC could range. To make matters worse, the diameter of the balls decreases as the pitch gets smaller.

Fanning out the traces on a BGA chip and the manufacturing process is fraught with challenges. For example, a BGA chip with a 1.0 mm pitch and a 0.45 mm landing pad can be routed with a 0.18 mm trace on a channel. A channel in BGA routing means the space between two landing pads on the X or Y-axis.

Typically, squeezing a 0.18 mm trace between two 1.0 mm pitch is not an issue, except that BGA’s pads are arranged in a dense grid pattern. This means you’ll need to figure out how to connect the inner pads to their respective nets. The task gets much more complicated when you have a BGA with half the pitch size.

4-layer PCB stackup process

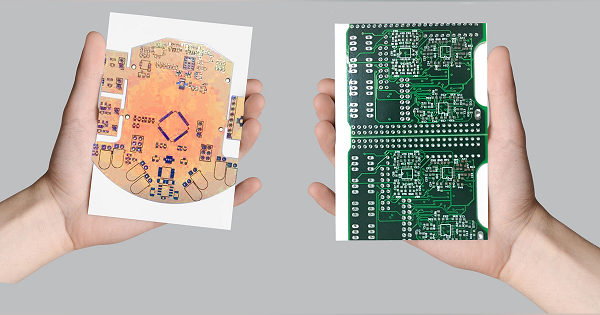

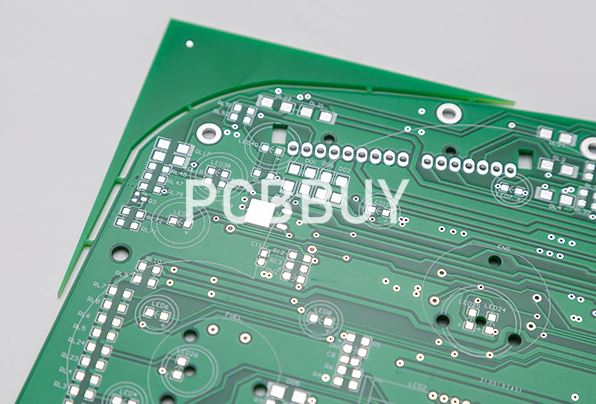

In terms of PCB stackup, 4-layer PCBs are the second most common option in multilayer boards. These PCBs have four layers to route electrical signals. These layers are sandwiched together, with a top and bottom layer on the outside and two inner layers contained between them. The top and bottom layers are where components and routing are placed.

The inner layers, however, cannot make outside connections, so they are often used as power planes or for signal routing, which helps enhance the quality of trace signals and reduces EMI emissions. It is not recommended to make the inner layers signal layers — if you need four signal layers, it is recommended to look into a 6-layer board.

The two inner layers are separated from each other with a core layer, and the top and bottom layers are separated from the inner layers by prepreg. This results in a layer stackup that looks like the following:

· Top layer

· Prepreg

· Inner layer 1

· Core

· Inner layer 2

· Prepreg

· Bottom layer

Industry Category