How to make Aluminum PCB?

By:PCBBUY 06/10/2021 17:52

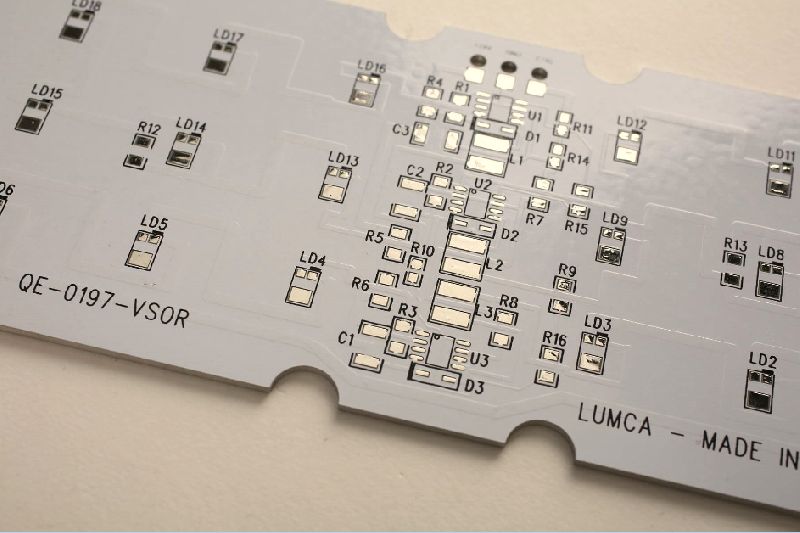

When you hear the names Aluminum Clad, Aluminum base, Metal Clad Printed Circuit Board (MCPCB), Insulated Metal Substrate (IMS), Thermally Conductive PCBs, etc., do know that the PCB type in question is synonymous to Aluminum PCBs.

From the name, you can already tell that aluminum PCBs contain aluminum as one of the materials. Indeed, these PCBs have a metal core at the base material, with aluminum being one of the critical components. What's more, there's the presence of a thin layer of thermal, dielectric material and electrically insulating material.

Why to use Aluminum PCB?

Since the emergence of aluminum PCB technology in the 1970s, several industries and individuals have augmented demand for production. Suppose you're planning on using applications that have heat dissipation and wish to control the temperatures. In that case, Aluminum PCB is the right choice for you.

Aluminum is known for transferring heat away from significant components on the board. In doing so, your PCB is kept free from the dangers of heat damage. Moreover, it is highly durable and can serve you a long time compared to other materials like fiberglass.

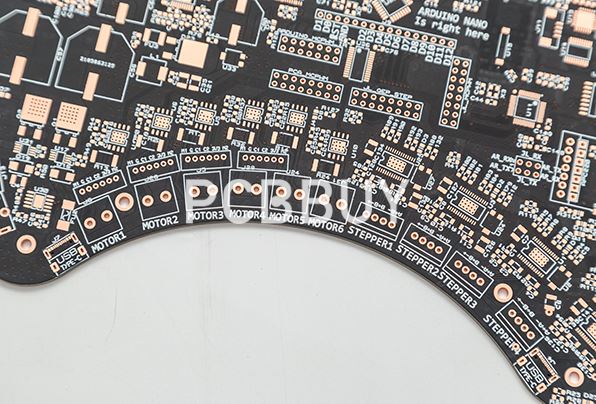

What are the types of Aluminum PCB?

Even though all-aluminum clads work the same way, i.e., in heat dissipation, different types have individual characteristics based on their design and structure. The following are the types of aluminum clads that you should be know.

Through-hole aluminum PCB

When we design through-hole aluminum PCB, the manufacturer backfills and pre-drills a single aluminum layer and then applies the laminate material. There will be a formation of a core of multilayer constructions after this process. Afterward, they laminate the thermal materials on the two sides of the board with thermal bonding materials. The final touch involves drilling on the assembly.

Flexible aluminum PCB

A flexible aluminum PCB is a recently marketed circuit board with a polyimide resin integrated with ceramic filters upon purchase.

The two materials’ essence is to increase insulation, flexibility (you can twist or fold the PCB to any shape and retain the form), and thermal efficiency. What’s more, their application is cost-effective since you won’t need to purchase connectors or cables. It’s disadvantageous because you can’t alter or modify the final product once you acquire a specific shape.

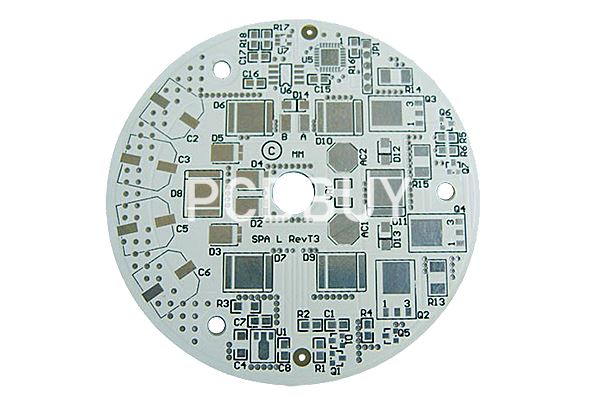

Multilayer aluminum printed circuit board

Multilayer aluminum PCBs have multiple-layer of thermally conductive dielectrics. The design constitutes one or more layers of circuitry found in the dielectric with blind vias representing thermal or signal vias.

An advantage to using multilayer IMS PCB is the straightforward and operative solution they offer for heat conductivity in complex products. Contrary to that, they’re costly and can’t easily engage in heat transfer in single layer designs. Their application is often in power supply products.

High thermal conductivity aluminum PCB

In this type of PCB; the insulating layer is an epoxy resin material. The epoxy resin should have excellent thermal conductivity.

High-frequency aluminum PCB

With high-frequency aluminum PCB, the insulating layer has a polyolefin or polyimide material. Other times, it can be woven fiberglass between an epoxy resin. The purpose of the materials is to improve the flexibility of the PCB.

How to solve difficulties during the aluminum PCB manufacturing?

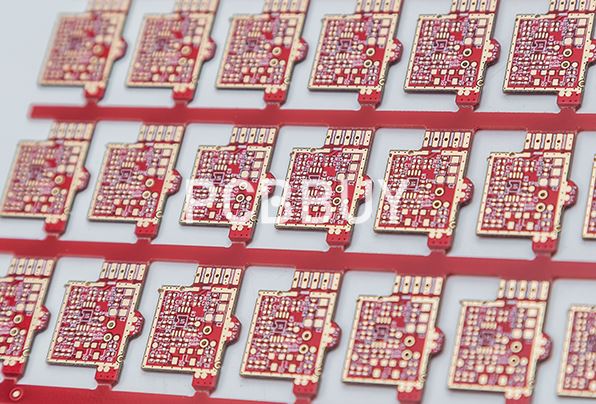

Copper etching

Ideally, the copper foil you use in the circuit layer should be thick. A higher standard than this, which is more than 3oz, will force you to compensate for the etching’s width requirement. Failure to do so will make the width intolerant to the etching. Therefore, you need to control the etching factors carefully, compensation being a major one.

Solder mask printing

A thick copper foil in this PCB design hinders solder mask printing of aluminum PCBs. In other words, a thick layered trace copper leads the etched image to have a vast difference in the trace surface and baseboard. Thus, printing becomes difficult.

A quick way to solve this problem is by using a quality solder mask oil. Alternatively, you can fill in the resin before the solder mask.

Machine-made

Manufacturing an IMS involves drilling mechanically, molding, and v-scoring, among others, centered on the internal via or holes. To combat this, use the electric milling and professional milling cutter for manufacturing products of a lower volume. Additionally, adjust the drilling parameters to stop burr production.

Industry Category