How to measure PCB temperature?

By:PCBBUY 05/18/2021 17:29

As an important element of PCB, temperature influences safety, reliability and performance in PCBs. High temperatures can quickly lead to malfunctions and permanent damage. So it is really important to detect temperature of PCB.

Several circumstances can introduce heat into the workings of a PCB. A component mounted to the PCB might produce excessive heat. An external element — for example, another component in a complex system like an aerospace system or medical application — might generate excessive heat. Heat might build up in the PCB because of inadequate ventilation. Or during PCB assembly, the heat produced during drilling and soldering might cause undue thermal stress on the components and lead to defective boards.

Whatever the reason, engineers need ways to manage heat to ensure that PCBs can survive the high thermal stresses they will inevitably encounter. What are some effective PCB heat dissipation techniques and ways to prevent PCB temperature rise? In this passage we will focus on the topic and please follow our content below.

Why Is monitoring PCB temperature important?

Monitoring PCB temperature is critical because high temperatures can alter the structure of the PCB and diminish its performance or cause it to break down.

PCB temperature measurement is also critical because the problems that result from high temperatures do not remain localized. They can quickly spread to other components of the PCB and cause a cascade of malfunctions and damage.

Excessive heat in a PCB board can cause the following types of damage:

Loss of structural integrity: Excessive heat can damage the integrity of a PCB. The layers of a PCB are highly sensitive to fluctuations in temperature, and when they get too hot or cold, they expand and contract. Excessive heat can lead to warping in the lengths, widths and thicknesses of different PCB layers.

Disruption of circuit lines: Excessive heat can result in circuit damage as well. Circuit lines expand and change shape when they overheat. Once this happens, the circuits become susceptible to frequency shifts, distortions and straight losses. Their conductor impedance can also shift from its standard value of 50 ohms. Millimeter-wave circuits and microwave circuits, in particular, have tiny, delicate components that can easily sustain damage if they expand and deform at high temperatures.

Incompatible rates of material expansion: The detrimental effects noted above are compounded by the fact that different materials expand at different rates. A PCB has two basic types of layers: dielectric layers and conductive metal layers. Because they contain different materials, they expand differently in response to heat. So an overheating PCB may experience further damage as the different types of layers pull apart.

Oxidation: Oxidation of PCB components is also a concern at high temperatures. Exposed dialectic material in PCBs does not have protection against oxidation if it does not have a protective laminate coating. In that case, the material may rust after exposure to high heat. Loss of transmission lines and a higher dissipation factor often result.

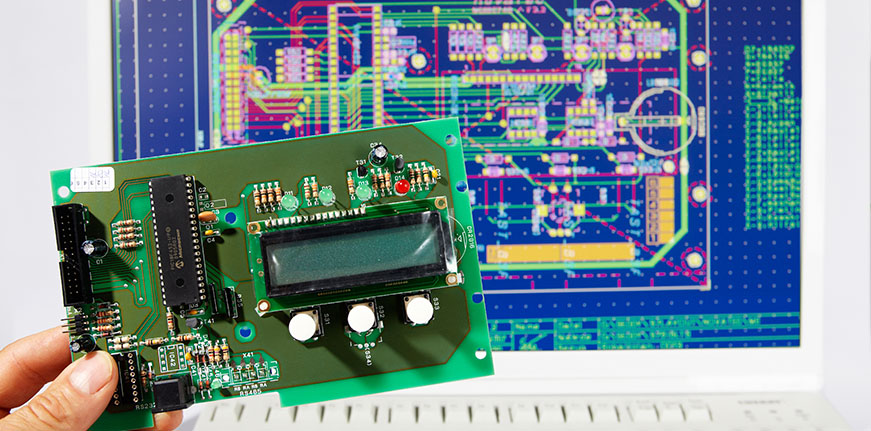

How to measure PCB temperature?

Before you measure PCB temperature, it’s essential to determine the primary heat source in the PCB — typically the microcontroller or microprocessor — as well as to locate the temperature sensors. Once you have these pieces of information, temperature monitoring can begin. PCB temperature measurement typically involves three different steps:

Place a ground plane between the temperature sensors and the heat source.

Connect the GND pins of each temperature sensor to the heat source’s ground plane.

Make sure the temperature sensors and the heat source remain close to each other on the PCB.

Following these steps will allow you to measure the temperatures of the primary heat source — and thus of the PCB as a whole — with accuracy and precision.

How much heat can a PCB stand?

How much heat a PCB can stand depends on the materials it is composed of. Materials with optimal thermal properties provide reliable resistance against the effects of high heat, whereas some materials stand up less reliably to high temperatures. The metric known as glass transition temperature (TG) helps indicate this resistance. For instance, FR-4 has a TG of about 135 degrees Celcius.

Industry Category