How to perform ICT test?

By:PCBBUY 06/26/2021 17:16

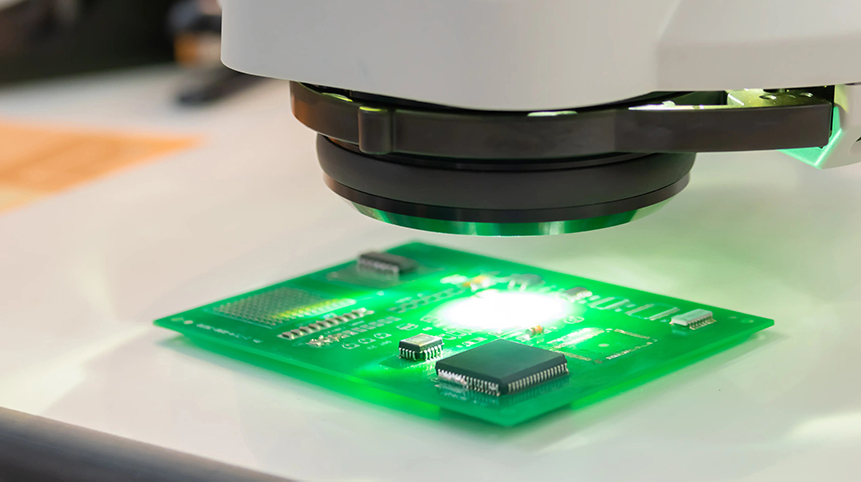

ICT, in the circuit board technology, is an abbreviation for In-Circuit Test. It's also known as the bed-of-nails In-circuit test. Structurally, it is an example of white box testing whereby an electrical probe tests a populated printed circuit board and checks for faultiness such as shorts, opens, etc.

This type of test method works by checking errors that may occur during fixing components onto the board. In doing so, you can easily replace any defective part. Moreover, they offer a fast and straightforward way of assessing the board’s manufacture and providing accurate results. ICTs can also utilize suction cups to check the soldiers’ sturdiness and the malleable strength of chips.

What are the advantages of ICT test?

In a like manner to all technologies, ICT has its downsides and upsides. Even though the advantages of ICTs offset the disadvantages, knowing the advance’s expectations is crucial.

ICT has some significant advantages that have been the reason manufacturers opt for it for centuries.

They include:

· In contrast to the AOI and flying probe testers, it can test the ball grid array assemblies (BGAs).

· Straightforward interpretation: the ICT system quickly locates the faultiness and presents it to you in a matter of minutes. You may not need professionally skilled personnel to proceed with the interpretation.

· Fast/ Time-effective: it roughly takes 1 minute in comparison to a flying probe tester that may take about 25 minutes. Being short is in regards to contacting all the board’s test points at once.

· Easy program generation: an ICT tester is effortlessly programmed. In that, you can take files from the PCB outline to make the essential program.

· It can test functionality as well as assembly defects as ICT systems can handle complex testing methods.

· Cost-effective: The high speed helps in quick recovering of the expense of setting up the fixture and program. It is especially true when considering boards that you assemble in large volumes.

· ICT platforms: The testing platform for ICT is available in both Windows and UNIX OS, making it universal.

· The testing can carry out several tests without applying power to the Device Under Test (DUT). It ensures a safe test and protects the board from any damage.

· Coverage: For manufacturing defects, it has high failure coverage. A more straightforward explanation for the increased range is the board’s complexity.

How to perform the PCB test method?

Upfront cost and unit cost

Upfront cost is the payment made in advance to the manufacturers before the testing and inspection starts. Unit cost is an expenditure incurred to produce, store, and sell one department unit of a particular product or service.

Cost is also inclusive of the maintenance you'll need to make on the PCB once in a while. An instance, even if your products design changes, you may only need a program change. In ICTs, however, you will need a new fixture and components.

The programming cost frequently depends on the board assembly process’s complexity but is often the same for test solutions, about £2000. Other charges vary with the test method itself and the PCB in question. For example, fixture costs of FTPs are zero because they are fixtureless. ICT fixtures can go up to £4000.

Coverage

Coverage means how much of the circuit board you can test. Both ICT and FTP carry out Manufacturing Defects Analysis (MDA). It allows for defects that are likely to occur, such as open circuits, shorts, diode, transistor orientation, and voltage measurement.

As an illustration, most FPTs offer some form of limited optical inspection that adds to the coverage of components that can't be accessed electrically.

Development preparation time

It refers to the length of time a PCB testing method takes during the circuit board or project’s basic check-up.

Customized

Manufacturers specifically design customized test products according to the buyers’ desires or specifications. On that note, you’ll find different test methods possessing varied shapes, sizes, features, etc., that best fits your board.

Ability to adapt to various designs

A PCB test method that adapts to various circuit board designs enables a manufacturer to test diverse boards with no limitations. PCB designs contribute to the functionality and regulatory process of the panels. Thus, a high adaptivity will highlight the board’s quality.

Expected quantity

You can use some test methods with large-scale type products. With others, it is preferable to have a small number of products. For instance, ICTs test large quantities of PCBs, often at the same time. Yet, FPT’s test a small amount as it has limited features.

Budget

A test method’s budget estimates the expenses you need to cater for over a specific time. Let's say you want to use an ICT test; you will need to evaluate a 3 to 4-year budget for the machine or procedure. That will include all the equipment you are to use.

PCB design/complexity

A quality test program relies on the quality of your Computer-Aided Design data and schematics. CAD data generates the basic test program and ensures you source the information from the original board design. Quality dense and unpopulated PCBAs are essential for tuning in the programs and making any fixtures. Consequently, this ensures the assemblies physically fit as intended.

Leading development time

Running times for test methods differ. As such, you'll have a flying probe test having an average lead time of 5-15 minutes. Some other larger boards can take 30+ minutes with the same method, but that rarely happens.

Industry Category