How to prevent PCB corrosion?

By:PCBBUY 06/04/2021 17:37

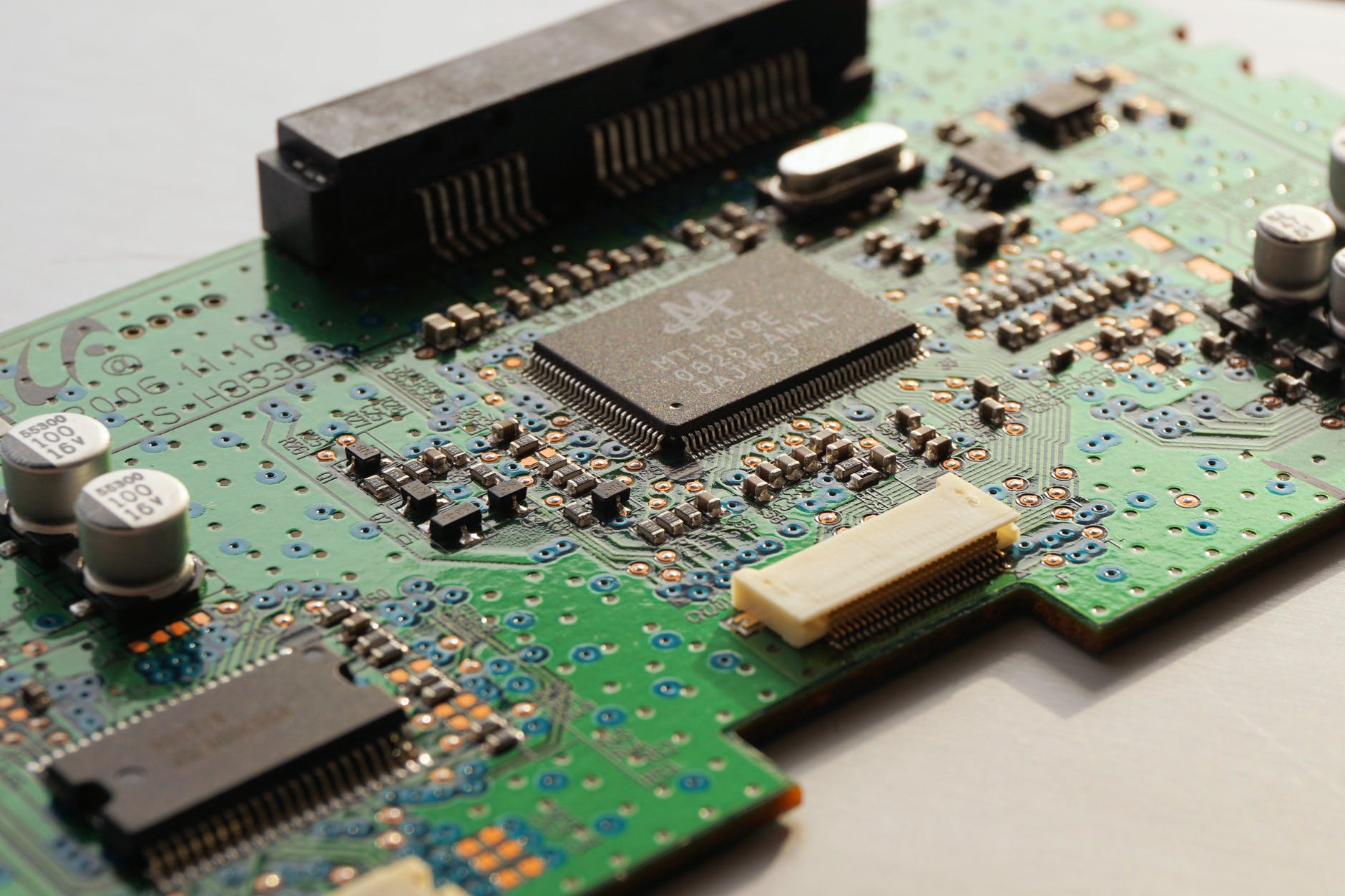

Corrosion is the process of oxidation that happens when oxygen bonds with metal, producing rust and causing the metal to flake off and lose its valuable chemical properties. Since printed circuit boards are largely made of metal and are exposed to oxygen, they must corrode eventually.

However, not all metals are created equal when it comes to corrosion. Some metals corrode almost immediately while some seem to never corrode. Metals that are highly resistant to corrosion include: Graphite, Gold Silver, Copper-nickel alloy. Metals that are highly susceptible to corrosion include: Plated tin, Lead, Copper, Plated nickel.

Corrosion is one of the major enemies of printed circuit boards. A sufficiently corroded circuit board won’t work, and the steady advance of corrosion is inevitable. In this passage we will focus on: why do printed circuit boards corrode, and what are some of the most common causes of PCB corrosion?

What are the types of PCB corrosion?

The metal in your circuit boards can corrode in several ways, including:

Atmospheric

This is the most standard type of corrosion. Metal is exposed to moisture, which contains oxygen, causing a reaction where the metal ions bond with the oxygen atoms and create an oxide. Copper experiences atmospheric corrosion very easily, which is not a problem for copper plumbing because corroded copper retains its mechanical properties. It does not, however, retain its electrical conductivity, so this is a big problem for circuit boards.

Galvanic

Galvanic corrosion occurs when different types of metals are in the presence of an electrolyte. In these circumstances, the more resistant metal will actually corrode faster than the baser metal it’s in contact with, so when gold is in contact with tin, for example, the gold will corrode much faster than usual.

Electrolytic

In this type of metal degradation, adjacent traces experience dendrite growth when ionic contaminated moisture infects the electrical voltage between them, creating metal slivers that result in a short circuit.

Fretting

With fretting corrosion, the action of closing solder-plated switches creates a wiping action that removes the surface oxide layer, allowing the layer beneath to oxidize. Eventually, excessive rust builds up and prevents the switch from activating.

How to clean corrosion PCB?

If your PCB gets corroded from water damage or from another source, cleaning it may repair it. Cleaning a circuit board requires everyday household items that even small companies can afford. However, only someone with a fundamental knowledge of electronics should attempt to clean a PCB. The process involves disassembling the board and avoiding damaging the components. When you separate the PCB from an electronic, stay away from water and disconnect the device.

You can use a variety of tools to clean a PCB, but certain items work best for eliminating corrosion. Cleaning a circuit board with corrosion involves the following materials:

Baking soda

The alkalinity and abrasive qualities of baking soda make it a perfect cleaner for corroded PCBs. It clears and neutralizes any corroded areas without damage.

Deionized water

When you use water to clean a circuit board, you must make sure it has no contaminants. The ions in regular water have conductive properties that degrade electronics. Meanwhile, deionized water has no contaminants or ions that cause damage.

Household cleaner

A phosphate-free household cleaner can help you remove dirt and corrosion effectively. Phosphates protect PCBs from corroding, but they also act as a major source of water pollution.

Thin, soft-bristle brush

If you do not have a specialized PCB cleaning tool, a toothbrush or paintbrush can also work. A brush with soft bristles will not scratch the board’s delicate components.

Lint-free towel

Cloths made from microfiber and other lint-free fabrics speed up the drying process without leaving particles behind.

Oven

A simple household oven thoroughly dries a PCB when you use indirect heat. Never place a circuit board in the oven without ensuring the oven is off first, however.

Industry Category