How to solder PCB components?

By:PCBBUY 06/24/2021 18:09

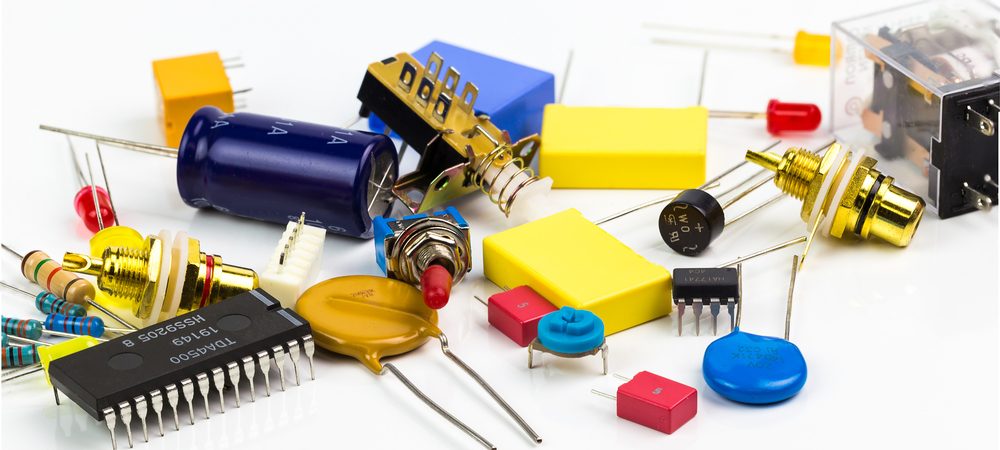

A printed circuit board component is an electrical part that goes into making the entire circuit board. PCBs consist of electrical elements such as diodes, capacitors, fuses, and resistors. For a PCB to function effectively, each component must play its role. If one part fails, then the PCB may fail to function as intended.

In this passage we will help you getting into the PCB components knowledge and the process of soldering PCB components. Come and check for the contents we provide for more information.

How to choose the right PCB components?

Circuit boards may seem somewhat incomprehensible, but its components matter a lot. The functioning of a PCB depends on its members. So, how do you go about choosing the right PCB components? Here’s what you need to do.

PCB design

Choose suitable components – For the best functioning PCBs, you need to select the right parts for your board. Go for the best materials that will suit your board. Ensure that your diodes, anodes, and transistors are of the highest quality.

Use schematics to plan your project

Schematics are of importance when designing a PCB. With the help of schematics, you will be able to better position. To know where every PCB will fit how to maintain and repair your PCB in case of damage.

Required space component size

What’s the size of your electronic component(s)? If it’s too large, then you may require a giant board. Still, you may need larger components on your PCB for better functionality.

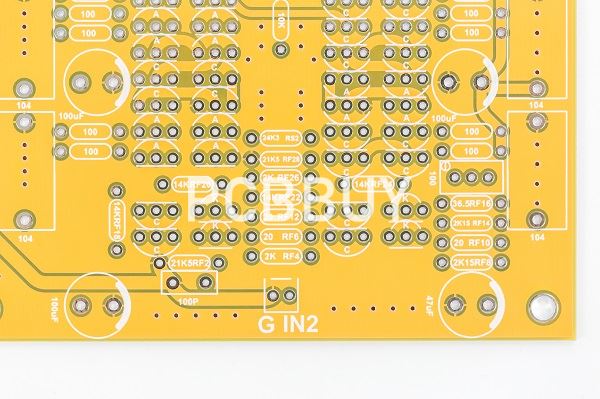

Consider component footprint

Your PCB component footprint has to include important pieces of information. Things such as assembly, placement, and part numbers are invaluable and need to be present in a component footprint. When creating a PCB footprint, make sure that you keep your entire datasheets handy. Also, understand the standard package sizes, and watch for through-hole sizes and locations.

Follow acceptable grounding practices

When designing a PCB, you need to stick to some grounding rules. Grounding is essential in your design process. Without a stable ground, you may not be able to ensure the passage of clean signals from one component to another. Some essential grounding practices involve leaving nothing unattached, grounding before routing, and minimizing series vias.

PCB soldering-choose right components

PCB soldering may seem to be a straightforward step, but you may end up with low board if you do it wrongly. If you desire to have a good board, ensure that you go for the right equipment. Make sure that the soldering iron and the solder itself are of the highest quality. If you employ the wrong components, you may end up with a printed circuit board that won’t serve you properly.

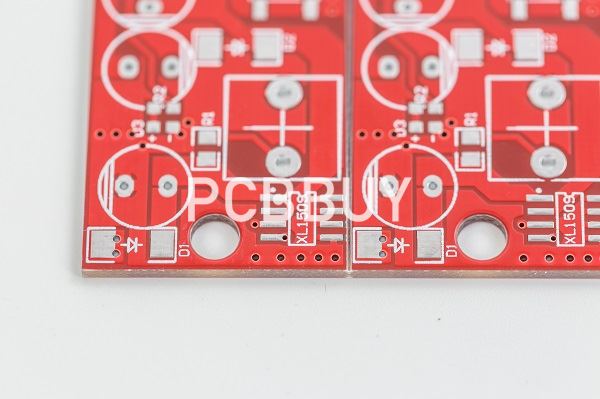

Separate lead from lead-free components

For many years, leaded solder has been a popular go-to substance in rework and electronic manufacturing. But in the last few decades, there’s been a growing concern for an environmental and increasing problem with products made using lead. The choice between leaded or unleaded components depends on the size of your project.

However, due to the latest government directives, you may have to go for unleaded components. Lead-free components are known for being environmentally friendly and not hazardous to humans.

How to Solder PCB Components?

Soldering involves using a filler material, also known as solder, to join some metal pieces together. Soldering takes place at relatively low temperatures compared to welding and brazing that require high temperatures.

Solder PCB components

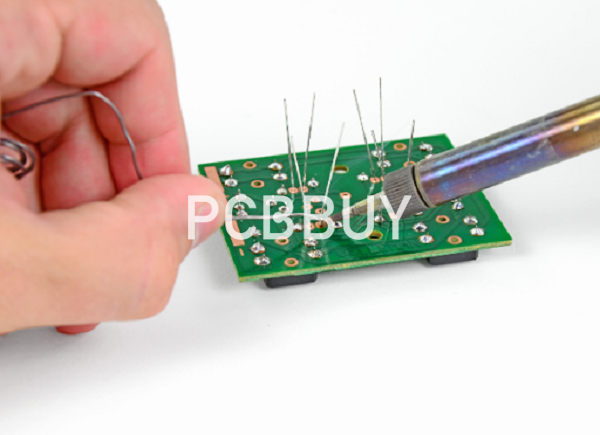

To solder PCB components, you’ll need the right equipment and a clean working surface. You begin the whole process by placing pieces into the holes. You need to ensure that you place the components so that the legs effectively come out on the same side as the solder pads. On the PCB solder side, make sure that you carefully bend the legs of components a bit. By doing so, it will not fall out if you flip the board upside down. In short, when soldering components on a printed circuit board, make sure that you have the right tools for the job. Work on a clean surface while ensuring that you follow all the steps. Don’t forget to keep all the safety precautions to don’t injure yourself or your colleagues.

How to place components on PCB?

Placing components on a PCB isn’t a difficult task. First, you have to group the elements by function. Next, you need to keep the details away from the dissipating area. After that, make sure that you place the board-to-wire connectors near the edge. After that, get the orientation of the components standardized before finally making space for copper traces.

How to remove components from PCB?

Removing parts on a PCB is an easy three-step process. First, you need to inspect the size of the solder joints on the role that requires removal. Next, you need to apply a small amount of liquid flux to solder joints of features you want to remove. Lastly, carefully place a heated soldering iron tip on the board’s component side's lead to remove the part (s).

Industry Category