How to the Attach Heat Sink to PCB through 7 Methods?

By:PCBBUY 01/13/2023 16:58

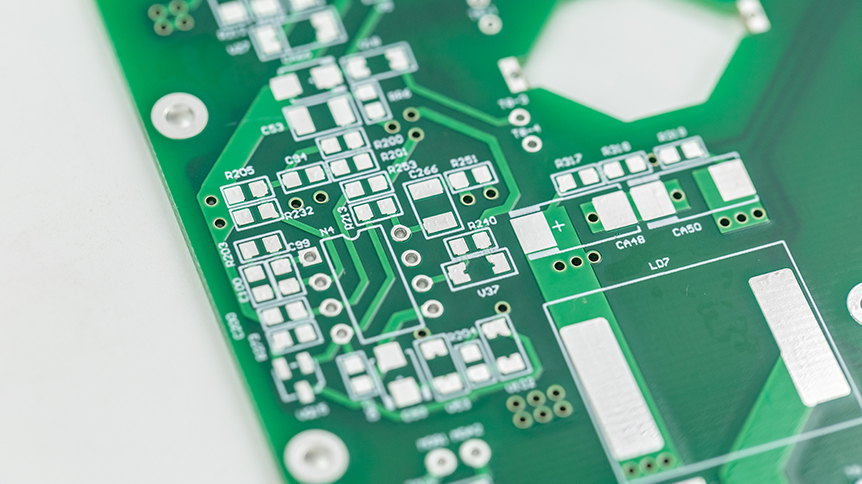

Heat sink PCB is a type of circuit board that can dissipate high surface temperatures. Power semiconductors, diodes, and resistors are the causes of this temperature. This type of PCB is becoming popular in the world today. Most printed circuit boards feature a heat sink.

Heat sink PCBs are one of the best forms of thermal management. This circuit board works by dissipating heat from critical components. Heat sink PCB is ideal for use in applications that generate heat. This PCB absorbs or dissipates heat when the heat affects the device. And if you are searching for more information about heat sink to PCB, please check and read for more information in this passage.

How to heat sink to PCB with hardware?

There are many ways to attach a heat sink to a device. The most commonly used methods include thermal tapes, push pins, spring loaded screws and clips.

Thermal Tapes

Double-sided thermal adhesive tapes are a quick and inexpensive way to stick a heat sink to the device. This method usually works quite well if (1) the heat sink is small and light, (2) the top surface of the device is adequately flat, and (3) a good thermal tape is used. However, for heavy heat sinks or for systems that need to pass shock and vibration test, thermal tapes are not secure enough, and the weight added to the device may even damage the device under shock or strong vibration. In addition, thermal tapes also perform as an interface material (TIM) but their thermal impedances are often much higher than other good TIMs.

Push Pins

Spring loaded push pins provide an easy and precise way to attach a heat sink to the device and the printed circuit board. The pressure between the heat sink and the device can be calculated and controlled by choosing the right spring. The most reliable push pins are made of spring steels and they work great at high temperature or in harsh environment. Plastic (Nylon) push pins are cost effective alternatives when the temperature in a system does not constantly exceed the glass-transition temperature (Tg) of the plastic.

What are the types of PCB heat sink?

Heat sinks are available in various types. Each of these types has its function. However, they share some common characteristics or features. Heat sinks are mostly made from metal like aluminum or copper. The commonest designs for a heat sink are the fin layout. Some versions utilize stamping and pins to increase the surface area and heat transfer rate.

Passive heat sink

A passive heat sink doesn’t feature additional products while cooling a component. It isn’t assisted by additional processes. These heat sinks don’t have any mechanical components. They dissipate heat through the convection process. When you use this heat sink on PCB, it gives reliable results. Experts recommend that engineers should maintain the flow of air across the fins of this heat sink.

Passive heat sinks serve as a standalone solution since they don’t use other cooling methods. These heat sinks are bigger than active heat sinks. Passive heat sinks disperse absorbed heat via the direct contact between them.

Active heat sink

This type of heat sink uses additional products to enhance its cooling capacity. Active heat sinks use powered processes like water pumps and fans. These processes or products help to increase the heat transfer rate. In some electronic systems, these coolers run off the internal power supply. This type of heat sink isn’t ideal for long-term applications. This is because it has moving parts.

What are the challenges of PCB heat sink?

The pressing of the circuit board with the heat sink turns out to be a challenge in both processes. The areal distribution of the thermal adhesive without air pockets between the two components was previously an unsolved problem and is particularly due to the low flow properties of the thermal adhesive. A sufficient distribution was achieved by pressing on with so-called pressure pins, but this method is only suitable to a limited extent. The result was often that, in particular in the case of thin and large-area ceramic substrates, the punctual and thus excessive force action resulted in the ceramic board breaking.

What are the methods of balancing the PCB heat sink?

The design of a PCB is a very complex process. The importance of heat sinks in PCB can’t be overstressed. Engineers need to consider some factors when implementing a heat sink on PCB. Heat sinks transmit thermal energy from electronic components into a cooling medium.

Heatsink PCBs are understood as PCBs that are able to dissipate high surface temperatures. Generally, these temperatures are caused by power semiconductors (transistors, thyristors, diodes and LEDs) as well as resistors. The following methods are suitable to dissipate the heat:

• The use of heat transfer compounds

• Higher copper thicknesses

• Heat dissipation using a metal core

• Heat dissipation using a metal heat-conducting plate

What are the applications of PCB heat sink?

Heat sink PCBs are used in several applications due to the functions they perform. These circuit boards are ideal for high-performance applications. They are also suitable for use in devices that produce a high amount of heat.

LEDs

Heat sink PCBs are commonly used in Light-emitting diodes (LED). These PCBs provide effective cooling for LED pcb. Heat sink circuit boards prevent excess heat from damaging LEDs. Most high-power LEDs feature heat sink PCBs.

Computers

Heat sink PCBs are a common component of computers. The CPU of computers needs a heat sink. Electrical activity in the CPU produces a good amount of heat. This may cause damage to the chipset. A heat sink helps to offer a good path for heat to pass through. The CPU comes with a heat sink. Some manufacturers use a particular type of heat sink for their CPUs.

Industry Category