Immersion Tin PCB Finish

By:PCBBUY 08/30/2025 17:14

Introduction to Immersion Tin PCB Finish

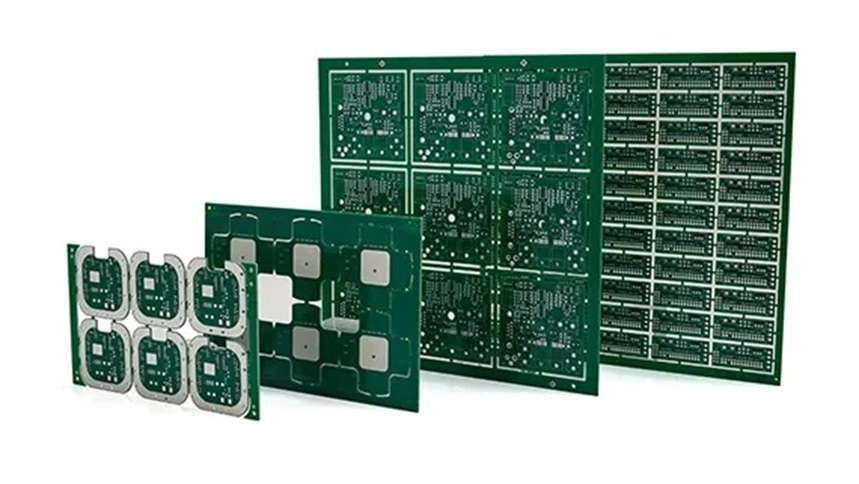

One of the most important aspects of the printed circuit board (PCB) production is the surface finish. Not only does it protect the copper surface against the oxidation process, but also provides a confident solderability in the assembly process. Immersion tin PCB finish has gained popularity because of its flat surface, high solderability, and adherence to the RoHS standards among the other types of finishing.

We are PCBBUY, and we specialize in fine immersion tin PCB finishes to satisfy the requirements of high-end electronics production. Our high level of quality and automated production lines make our production consistent, reliable and perform well on every order.

The Role of Immersion Tin PCB Finish in Electronics

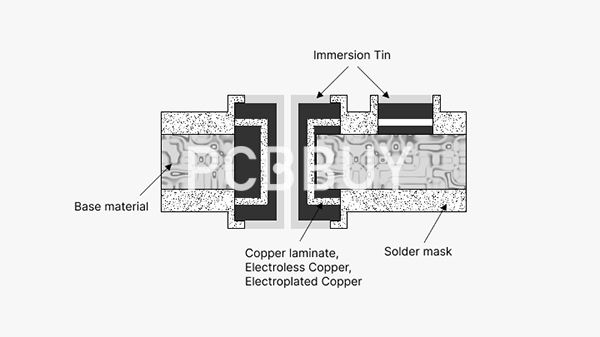

Immersion tin PCB finish is a controlled chemical operation in which a thin layer of tin is deposited on exposed copper surfaces. This coated layer of tin inhibits oxidation of copper and offers a superior solderable surface.

Important advantages of immersion tin are:

• Protection against oxidation and corrosion.

• Flat surface ideal for fine-pitch components and BGA assembly.

• Lead-free and environmentally friendly, fully compliant with RoHS.

This has made the use of immersion tin a favorite in terms of use in processes that are demanding in terms of precision and reliability.

Technical Principles of Immersion Tin PCB Finish

The immersion tin process relies on a chemical displacement reaction. The copper reaction with the immersion tin solution is controlled and a thin uniform layer of tin is deposited on copper.

•Tin thickness: typically 0.8–1.2 μm.

•Surface flatness: provides small-pitch IC compatibility.

•Adhesion: the layer of tin bonds itself firmly to copper enhancing the strength of the solder joints.

The procession of immersion tin PCB finish largely is a matter of accuracy in surface preparation, chemical balance, and process control where PCBBUY has acquired experienced skills.

Step-by-Step Process of Immersion Tin PCB Finish at PCBBUY

1. Surface Preparation

PCB is washed, de-greased, and etched under a microscope to eliminate oxidation and contaminancy.

2. Immersion Tin Deposition

Boards are plated in a proprietary tin plating bath. PCBBUY maintains temperature, pH and chemical concentration to provide a uniform and free of defects coating.

3. Rinsing and Drying

Various rinses and regulated drying avoid contamination and give the surface of the tin a smooth appearance.

4. Inspection and Testing

Thickness measurement, adhesion testing and solderability tests are determined on each PCB as per IPC standards.

Through automated process lines, PCBBUY can deliver consistent tin deposition, excellent flatness and quality in both small and large volume production.

Advantages of Immersion Tin PCB Finish

Compared with other surface finishes, immersion tin PCB finish offers unique advantages:

|

Surface Finish |

Flatness |

Lead-Free |

Shelf Life |

Suitability for Fine-Pitch |

Cost |

|

Immersion Tin |

Excellent |

Yes |

6–12 months |

Very high |

Medium |

|

OSP |

Good |

Yes |

6 months |

Good |

Low |

|

HASL |

Poor |

Optional |

12 months |

Limited |

Low |

These benefits make immersion tin particularly attractive for high-density interconnect (HDI) boards, BGA packaging, and fine-pitch SMT applications.

Problems and Solutions of PCBBUY.

Even though immersion tin PCB finish has powerful strengths, it possesses certain difficulties as well:

The development of tin whiskers may be uncontrolled.

• Shelf life restrictions need close storage.

In PCBBUY we combat such problems through:

• Anti-whisker advanced chemical formulations.

• Real-time control of plating bath chemistry.

• Giving packaging and storage instructions to customers to prolong the life of boards.

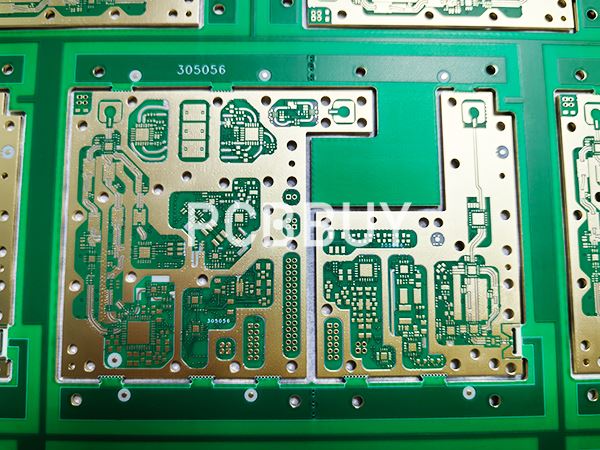

Applications of Immersion Tin PCB Finish

Immersion tin is in common use in:

• Telecommunications equipment

• Industrial control systems

• Automotive electronics

• Medical devices

PCBBUY has been able to provide immersion tin PCBs to customers in these sectors and both perform well and at the same time meet the high standards.

PCBBUY’s Expertise in Immersion Tin PCB Finish

PCBBUY is providing immersion tin PCB services of world class having:

• State of art manufacturing lines with standardized tin coating.

• Strict IPC-A-600 and IPC-6012 compliance for surface finish quality.

• Scaleable prototype to mass production order.

• Full testing such as cross-section, solderability, and checking of surface roughness.

We will strive to ensure that we provide cost-effective and reliable immersion tin PCB finishes to fulfill the changing requirements of our customers around the world.

Why Choose PCBBUY for Immersion Tin PCB Finish

• Expertise: Decades of experience in PCB manufacturing and finishing.

• International Presence: Efficient export solutions, to the clients across the globe.

• Efficiency: Fast turnaround times with competitive pricing.

• One-Stop Service: PCB fabrication, surface finishing, and assembly under one roof.

When you use PCBBUY, you are collaborating with an established manufacturer that only prioritizes quality, precision, and long-term reliability.

Conclusion

The immersion tin PCB finish remains one of the most effective and reliable surface treatments for modern electronics manufacturing. Its flatness, solderability, and environmental compliance make it highly suitable for high-density designs and precision assembly.

At PCBBUY, our advanced immersion tin processes, rigorous testing, and customer-focused services set us apart as a trusted partner in the global PCB industry. Whether you need prototypes or large-scale production, PCBBUY ensures consistent quality and performance with every immersion tin PCB finish.

Industry Category