Lead-Free Solder Paste in PCB Assembly

By:PCBBUY 10/30/2025 16:39

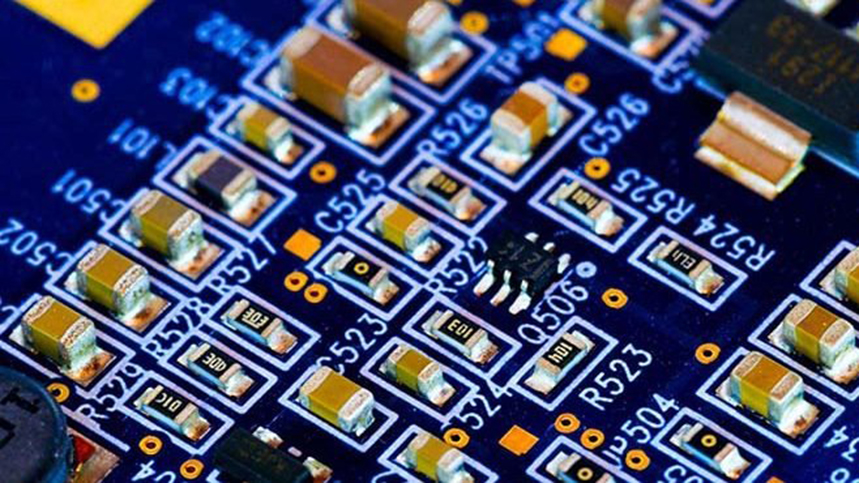

As global electronic manufacturing shifts toward environmental sustainability and compliance with regulations like RoHS, the use of lead-free solder paste has become a critical standard in modern PCB assembly. For industries such as automotive electronics, medical devices, aerospace, telecom, and industrial control systems, achieving reliable solder joints is essential to product performance and lifetime.

At PCBBUY, we integrate advanced soldering processes and precise print control to ensure the best performance when applying lead-free solder paste in SMT and reflow assembly. This article explains what lead-free solder paste is, how it differs from traditional tin-lead solder, and how PCBBUY ensures consistent quality in PCB production.

What Is Lead-Free Solder Paste?

Lead-free solder paste is a mixture of metal alloy powder and flux used during SMT (surface mount technology) PCB assembly. Unlike traditional Sn-Pb solder paste, lead-free formulations contain no lead, making the manufacturing process more environmentally friendly and compliant with safety regulations.

Common lead-free alloy compositions include:

|

Alloy Type |

Composition |

Melting Point |

|

SAC305 |

96.5% Sn, 3.0% Ag, 0.5% Cu |

~217°C |

|

SAC405 |

95.5% Sn, 4.0% Ag, 0.5% Cu |

~219°C |

|

SnCu |

99.3% Sn, 0.7% Cu |

~227°C |

Among these, SAC305 is the industry-preferred alloy for consistent wetting, mechanical strength, and thermal stability.

Why Lead-Free Solder Paste Is Important

1. Compliance with Global Regulations

Lead-free solder paste is required to meet:

-

RoHS (Restriction of Hazardous Substances)

-

WEEE (Waste Electrical and Electronic Equipment Directive)

2. Improved Mechanical Reliability

Lead-free joints tend to provide:

-

Better high-temperature fatigue resistance

-

Greater long-term stability in harsh environments

3. Sustainability and Safety

Lead-free materials reduce:

-

Toxic hazards during production

-

Environmental contamination during disposal

How PCBBUY Ensures High-Quality Soldering with Lead-Free Solder Paste

PCBBUY combines process control, testing systems, and quality standards to ensure excellent joint performance

1. Controlled Paste Storage & Handling

Lead-free solder paste performance depends on temperature and humidity.

At PCBBUY:

-

Paste is stored in temperature-controlled cabinets

-

Thawing and working time are strictly recorded

-

Automated traceability labels ensure batch management

2. Precision Stencil Printing with Aspect Ratio Control

Accurate solder volume is critical.

PCBBUY uses:

-

High-precision laser-cut stainless steel stencils

-

Controlled aspect ratio stencil openings

-

Automated solder paste inspection (SPI)

This ensures consistent coverage, reduces voiding, and prevents bridging.

3. Optimized Reflow Profile for Lead-Free Solder Paste

Since lead-free solder melts at higher temperatures, reflow curves must be carefully controlled.

PCBBUY employs:

-

Multi-zone convection reflow ovens

-

Fine-tuned temperature profiles for each board type

-

Real-time thermal profiling for process repeatability

This prevents common issues like tombstoning, cold joints, and oxidation.

4. IPC-A-610 Based Solder Joint Acceptance

Our inspection follows IPC-A-610 Class 2 and Class 3 workmanship standards depending on customer requirement.

Inspection methods include:

-

AOI (Automated Optical Inspection)

-

X-ray for BGA & QFN void analysis

-

Manual inspection by certified technicians

Applications Supported by PCBBUY Lead-Free Assembly

|

Industry |

Typical PCB Application |

Requirements |

|

Automotive |

ECU, LED driver boards |

High-temperature reliability |

|

Medical |

Monitoring and control boards |

Stable operation and safety |

|

Consumer Electronics |

Smart devices, wearables |

Fine-pitch soldering quality |

|

Telecom |

Network modules, RF boards |

Signal integrity and durability |

Why Choose PCBBUY for Lead-Free PCB Assembly?

-

Advanced SMT production lines

-

Strict environmental compliance

-

IPC-certified assembly technicians

-

Full testing and inspection capabilities

-

Fast prototype to mass production support

Our focus is always to help customers achieve reliable, durable, and high-performance electronic products.

Conclusion

The adoption of lead-free solder paste is not just a compliance trend—it is essential to ensuring product reliability and environmental sustainability. With optimized soldering processes, advanced inspection systems, and strict quality standards, PCBBUY delivers stable and reliable results across diverse PCB applications.

If you need professional lead-free PCB assembly with consistent quality and competitive pricing, PCBBUY is ready to support your next project.

Industry Category