Lead-free solder VS lead solder & Which one is better?

By:PCBBUY 06/23/2021 18:30

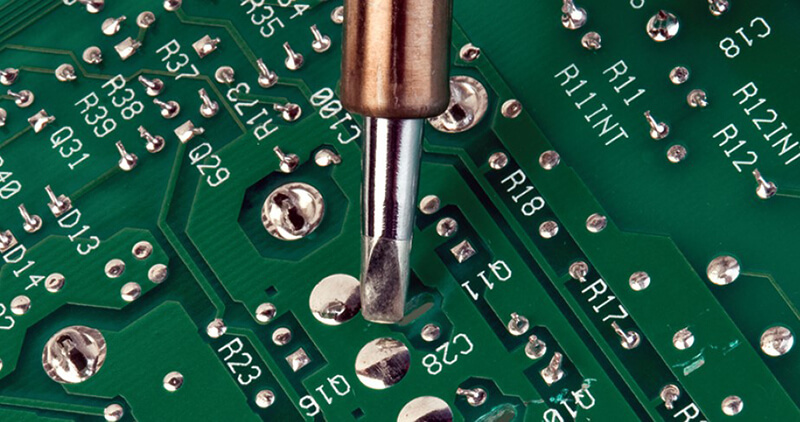

During the PCB manufacturing process, leader solder is one of very popular materials. But recent years, concerns have increased about the health and environmental effects of products containing lead on consumers. Most electronic manufacturers use solder to stick components to PCBs. Whether it is a lead-free or a leaded solder, they all serve the same function. Nevertheless, various devices and use cases utilize different soldering techniques.

Which solder is better to use in the electronic world? What are the differences between leaded solder and lead-free solder? In this passage, we will focus on these topics and please check and read the content below for more information.

What is lead-free solder?

The main reason why manufacturers are shifting to the use of lead-free solder is to eradicate lead from electronic production and waste recycling processes. In the past two decades, the electronic manufacturing world has experienced a dynamic development of alternative soldering materials centered on tin metal. This alternative approach uses materials with properties that are distinct from the lead and tin eutectic composition.

Since soldiers are effective at 80% of their melting point, they call for performances similar to the jet engine superalloys. However, solder joints requirements are continually increasing because of the rising density and stress properties from miniaturization. Therefore, lead-free solders need a PCB design, which accommodates the high melting point and anisotropic properties.

What is lead solder?

Generally, leaded solder is composed of tin and lead. The advantage of using leaded solder is its adequate flowing capacity. It has a lower melting point than lead-free solder; hence, presenting less thermal effects to components. Besides, when the solder cools down, it assumes a brighter appearance than lead-free solder, making it easy for you to detect issues like oxidation. Furthermore, lead solder is cheaper and easier to use than lead-free solder.

What are the differences of lead-free solder and lead solder?

The use of high quantities of lead in consumer products over an extended period causes harmful effects to the environment and people. Currently, companies have shifted to lead-free soldering to support their social responsibility efforts of protecting the environment. Thus, it is crucial to learn how lead-free solder compares with leaded solder and examine the better option for use.

Melting Point

Lead-free solder has higher melting point than lead solder. Lead solder has a melting point of 1830C, while lead-free solder has a melting point of 2170C. Now, these are the effects of the higher melting point of lead-free solder:

· The higher temperature of lead-free soldering oxidizes the solder quickly compared to the lower temperature of lead soldering.

· Like those containing plastic packages and electronic capacitors, some components are negatively affected by the high soldering temperature of lead-free solder.

· The high temperature of lead-free solder comes with significant component stress; therefore, low dielectric components are more vulnerable to failures.

· Lead-free solder components have several soldering surfaces. Companies often use tin on such surfaces because it is cost-effective. However, the tin generates a small oxidation coat on the outside that can lead to electroplating.

Eutectic

Manufacturers valued the use of tin and lead because it formed a eutectic mixture. In other words, the lead and tin composition have a lower temperature than the individual metals' temperatures. Although the electronic manufacturing world has not managed to discover another eutectic metal combination, it has invented a lead-free soldering technique that works well.

Health Concerns

Companies sensitive to environmental conservation state the poisonous nature of lead as their main reason for embracing lead-free soldering. Lead can indeed accumulate in the human body even from small prolonged exposures. Furthermore, lead can quickly enter your body through the skin, mouth, or nose. The paint and gasoline sectors have all gone lead-free. However, solder is among the remaining products that still use it.

In an industry experiencing high lead emission, workers are more vulnerable to the dangers of lead as they can quickly inhale it or get it by touching contaminated surfaces. Remember, lead is more dangerous to children. Therefore, take these health concerns seriously wherever you are using lead solder.

Cost

Leaded solder is cost-effective than lead-free solders. This is because lead is barely a tenth of the tin price, making leaded solder easily affordable. Furthermore, some manufacturers replace tin with silver in lead-free solders, making them even more expensive.

Wettability

Lead-free Solder has Poor Wettability than Leaded Solder. Low wettability makes the solder joint function ineffectively in meeting the demands of self-regulation ability, tensile power, and shear capacity. Consequently, low wettability causes a high rejection rate of solder joints, especially when you fail to conduct adjustments to cater to this shortcoming.

Physical Features

Lead-free solder has a negative joint reliability impact. From a mechanical influence point of view, lead-free solder is stronger than leaded solder. Furthermore, lead-free solder forms surface oxides, flux impurity, and alloy deposits that can cause poor contact resistance performance. Therefore, the shift from lead to lead-free electronic production is not a total replacement in electrical and mechanical features due to these reasons:

The lead is comparatively soft. You will realize that lead-free production solder joints are harder than lead manufacturing solder joints. This causes heightened intensity and minor modifications, which result in high reliability.

Lead-free soldering causes low wettability, igniting more problems, such as vacancy and tomb standing.

Industry Category