Minimum Trace Spacing in PCB Design Guide

By:PCBBUY 11/28/2025 17:19

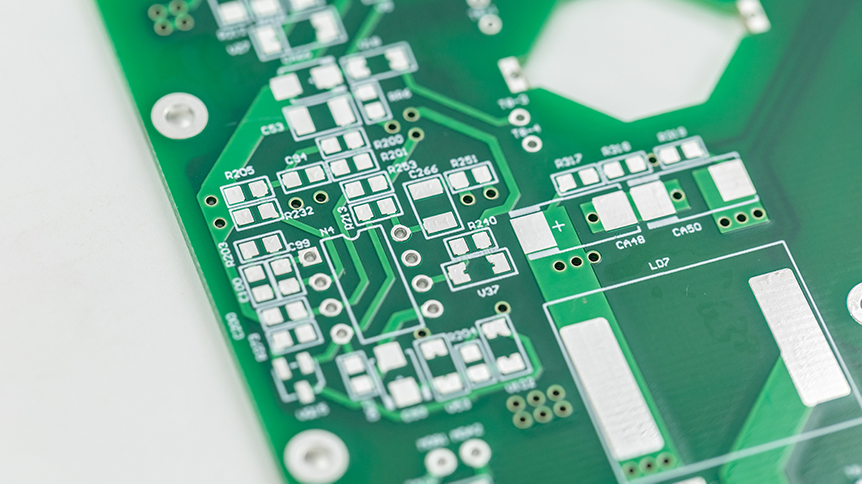

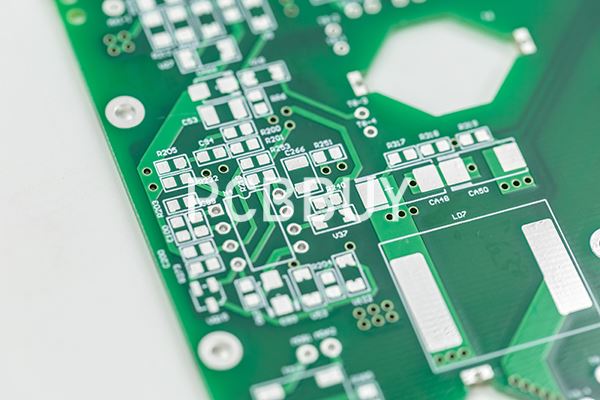

Minimum trace spacing refers to the smallest manufacturable clearance between two adjacent copper features. This parameter determines electrical safety, signal integrity performance, and manufacturability limits in high-density PCB designs.

As a PCB manufacturer serving global clients, PCBBUY often receives questions about ideal spacing, manufacturable limits, and how spacing affects cost. This article gives you a clear, beginner-friendly explanation while showing you the spacing capabilities we offer.

What Is Minimum Trace Spacing?

Minimum trace spacing refers to the narrowest allowed distance between two copper traces on a PCB. This spacing ensures that:

-

signals do not interfere with each other

-

high-voltage circuits stay safe

-

copper does not short during soldering or assembly

-

the PCB can be produced accurately by the factory

In simple terms: the smaller the trace spacing, the more difficult the board is to manufacture — especially for HDI or ultra-dense designs.

Industry Standards for Trace Spacing

Most PCB designers follow IPC standards, which give clear spacing recommendations. For example:

-

General electronics (IPC Class 2): 4–5 mil

-

High-end or mission-critical devices (IPC Class 3): 3–4 mil

-

High-voltage applications: spacing increases based on voltage requirements

-

High-speed circuits: spacing is often larger to reduce crosstalk

These values are general guidelines — actual manufacturability depends on the PCB factory’s equipment and process control.

What Factors Affect Minimum Trace Spacing?

The ideal spacing depends on a few real-world conditions:

1. Voltage

Higher voltage requires more clearance to prevent arc or breakdown.

2. Signal Speed

High-frequency or differential signals need more spacing to prevent interference.

3. Copper Thickness

Thicker copper requires more spacing due to etching limits.

4. PCB Material

High-frequency materials like Rogers allow cleaner etching compared to standard FR4.

5. Fabrication Capability

This is where PCB factories differ the most.

PCBBUY Minimum Trace Spacing Capabilities

PCBBUY supports a wide range of line/space capabilities to fit different markets and cost levels:

|

PCB Type |

Minimum Line/Space |

Notes |

|

Standard FR4 |

4/4 mil |

Stable for mass production |

|

Advanced FR4 |

3.5/3.5 mil |

Tight tolerance |

|

HDI PCB |

3/3 mil |

LDI exposure technology |

|

High-density / on request |

2.5/2.5 mil |

For premium devices |

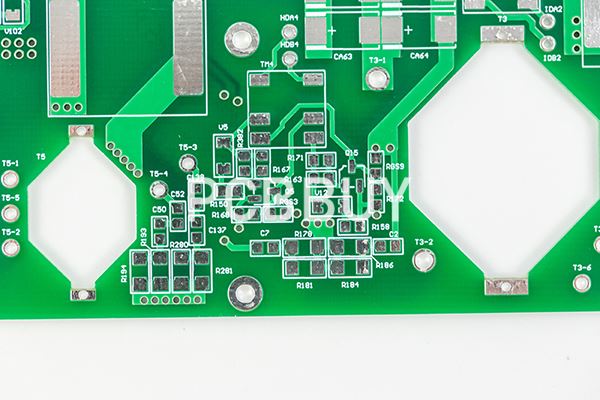

Why PCBBUY can achieve this:

-

Automatic LDI exposure

-

Controlled etching and cleaning lines

-

AOI inspection for micro-lines

-

Strict DFM checks before production

This combination ensures reliable fine-pitch boards with consistent quality.

Design Tips for Better Trace Spacing

If you're designing boards for reliable production, consider these tips:

-

Follow IPC spacing rules

-

Give more spacing to high-speed or sensitive signals

-

Keep differential pair spacing uniform

-

Use DRC rules inside Altium, KiCad, Eagle, or Cadence

-

Ask your manufacturer for DFM advice before finalizing the design

PCBBUY’s engineering team offers free DFM checks, helping designers reduce risk and avoid redesigns.

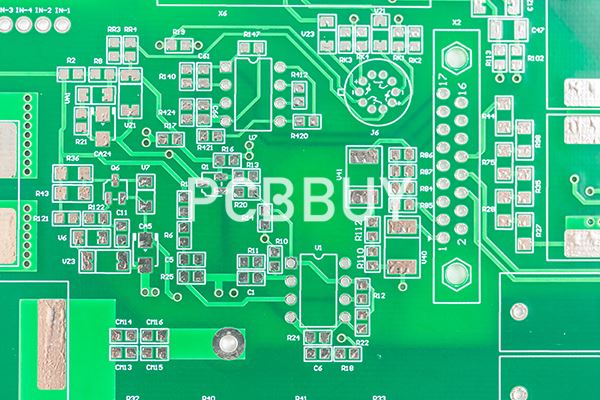

Why Choose PCBBUY?

✔ Stable fine-line capability

✔ Experienced with HDI and high-density consumer electronics

✔ Professional engineering review before production

✔ Fast prototyping + high-volume manufacturing

✔ Competitive pricing for global customers

No matter what industry you work in, PCBBUY can provide reliable minimum spacing solutions.

Conclusion

Minimum trace spacing is more than a rule — it's essential for signal integrity, safety, and manufacturability. With PCBBUY’s advanced production capabilities and strong engineering support, designers can confidently build boards with both standard and fine-pitch spacing.

FAQ

Q1: What is the recommended minimum trace spacing in PCB design?

Most PCB factories recommend 4 mil for standard boards and 3 mil for HDI boards.

Q2: Can PCBBUY manufacture PCBs with 3 mil spacing?

Yes. PCBBUY supports 3/3 mil for HDI and fine-line applications.

Q3: Does smaller spacing increase PCB cost?

Yes — finer spacing requires LDI exposure and tighter process control.

Q4: Do high-voltage circuits need larger spacing?

Correct. Higher voltage requires more clearance to prevent electrical breakdown.

Q5: What software can check spacing automatically?

Altium, KiCad, Eagle, Cadence, and almost all ECAD tools support DRC spacing rules.

Industry Category