Multilayer PCB Drilling Accuracy

By:PCBBUY 01/30/2026 17:33

In multilayer PCB manufacturing, drilling accuracy is a critical factor that directly affects electrical reliability, layer registration, and overall production yield. As layer count increases and via structures become more complex, maintaining consistent multilayer PCB drilling accuracy becomes increasingly challenging.

This article explains what drilling accuracy means in multilayer PCB fabrication, the factors that influence it, and how professional manufacturing control improves final product quality.

What Is Drilling Accuracy in Multilayer PCB?

Drilling accuracy refers to the ability to place drilled holes precisely at their intended locations and dimensions throughout the entire PCB stackup. In multilayer PCBs, drilling accuracy includes:

-

Hole position tolerance

-

Hole diameter consistency

-

Hole wall quality

-

Alignment between drilled holes and internal copper layers

Any deviation can result in breakout, insufficient annular ring, or unreliable via connections.

Why Drilling Accuracy Is Critical for Multilayer PCBs?

As the number of layers increases, the margin for error decreases. Poor drilling accuracy may lead to:

-

Inner layer breakout

-

Incomplete via plating

-

Electrical opens or shorts

-

Reduced product reliability

For high-density and high-layer-count PCBs, drilling accuracy directly determines whether the board can meet IPC requirements.

Key Factors Affecting Multilayer PCB Drilling Accuracy

Stackup Thickness and Material Stability

Multilayer boards involve thicker stackups composed of multiple prepregs and cores. Variations in material thickness or resin flow during lamination can cause dimensional changes that affect drilling accuracy.

Registration Between Inner Layers

Precise alignment between inner layers and drilled holes is essential. Any layer shift during lamination increases the risk of annular ring reduction or breakout after drilling.

Drill Bit Quality and Wear Control

Drill bit condition has a significant impact on accuracy. Worn or damaged drill bits can cause:

-

Hole position deviation

-

Increased hole roughness

-

Diameter inconsistency

Professional factories closely monitor drill bit life cycles to maintain accuracy.

Drilling Parameters and Machine Precision

Drilling accuracy depends on:

-

Spindle speed

-

Feed rate

-

Entry and backup material selection

-

CNC drilling machine calibration

Optimized parameters help minimize drill wander and vibration.

Design-Related Factors Influencing Drilling Accuracy

Design choices play an important role in achievable drilling accuracy:

-

Via size relative to board thickness

-

Aspect ratio limitations

-

Annular ring width requirements

-

Via-in-pad and microvia usage

Early DFM analysis helps align design intent with manufacturing capability.

Process Control Methods for Improving Drilling Accuracy

Controlled Lamination and Dimensional Stability

Stable lamination processes reduce internal stress and layer movement, providing a reliable base for accurate drilling.

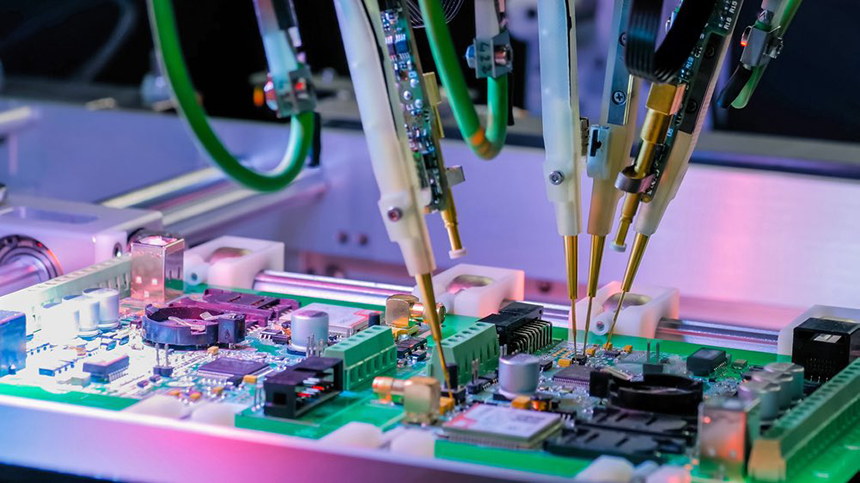

Precision CNC Drilling Systems

Advanced CNC drilling machines with high-speed spindles and real-time compensation systems improve positional accuracy and repeatability.

Drill Wear Monitoring and Replacement Standards

By defining maximum hit counts per drill size, manufacturers prevent accuracy degradation caused by tool wear.

Post-Drilling Inspection and Measurement

Hole position and diameter are verified through:

-

Automated optical inspection (AOI)

-

Cross-section analysis

-

Statistical process control (SPC)

These methods ensure drilling accuracy remains within specification.

Relationship Between Drilling Accuracy and Via Reliability

Accurate drilling ensures:

-

Uniform copper plating thickness

-

Strong via-to-layer connection

-

Reduced risk of thermal stress failure

In multilayer PCBs, drilling accuracy directly impacts long-term via reliability.

How PCBBUY Ensures Multilayer PCB Drilling Accuracy?

PCBBUY maintains high drilling accuracy through:

-

Optimized stackup engineering for dimensional stability

-

High-precision CNC drilling equipment

-

Strict drill wear management procedures

-

Comprehensive inspection and quality control

By combining process discipline with engineering expertise, PCBBUY delivers reliable multilayer PCBs for demanding applications.

Conclusion

Multilayer PCB drilling accuracy is a fundamental requirement for electrical performance, manufacturing yield, and long-term reliability. As PCB designs continue to evolve toward higher layer counts and tighter tolerances, precise drilling control becomes essential.

Choosing a manufacturer with proven drilling capability and process control is key to successful multilayer PCB production.

FAQ

What is drilling accuracy in multilayer PCB manufacturing?

It refers to how precisely holes are positioned, sized, and aligned with inner layers throughout the PCB stackup.

Why is drilling accuracy more difficult in multilayer PCBs?

Increased board thickness, tighter tolerances, and accumulated lamination stress make precise drilling more challenging.

How does drilling accuracy affect via reliability?

Poor drilling accuracy can cause insufficient annular rings or uneven plating, leading to via failure under thermal or mechanical stress.

Can PCB design improve drilling accuracy?

Yes. Proper via sizing, reasonable aspect ratios, and sufficient annular ring margins improve manufacturability.

How do PCB manufacturers control drilling accuracy?

Through controlled lamination, precision drilling equipment, drill wear monitoring, and post-drilling inspection.

Industry Category