Overview Guide of Medical PCBA Manufacturing

By:PCBBUY 10/21/2025 16:46

In the medical sector, accuracy and dependability are not a choice but they are matters of life. All circuit boards of a medical device should work correctly, which is why the diagnostics and treatment mechanisms are safe and accurate. This is where medical PCBA (Printed Circuit Board Assembly) emerge to be a keystone of the modern healthcare technology.

We are PCBBUY combining years of experience in the engineering field with modern technological production and obsessive quality control to produce medical-grade PCB assemblies that are produced to the highest international standards.

1. Understanding the Importance of Medical PCBA

Medical PCBA refers to the complete process of assembling electronic components onto printed circuit boards for use in medical equipment. These devices include ECG monitors, MRI scanners, infusion pumps, wearable health trackers, and implantable devices.

Unlike standard industrial electronics, medical PCBAs must meet tighter tolerances, biocompatibility requirements, and long-term stability. This is why choosing a reliable PCB manufacturing partner such as PCBBUY is essential for companies aiming to ensure both performance and compliance.

2. Design and Material Considerations in Medical PCBA

Medical devices operate in environments where temperature control, signal integrity, and durability are crucial. At PCBBUY, our engineers carefully select base materials and assembly processes tailored to each medical application:

-

High Tg FR-4 or polyimide substrates for thermal stability.

-

ENIG or OSP surface finishes to guarantee corrosion resistance and long-term reliability.

-

Gold-plated contact pads for improved conductivity in precision sensing circuits.

-

RoHS and ISO 13485 compliance to meet international health and safety standards.

Before production, each BOM (Bill of Materials) is reviewed by our DFM (Design for Manufacturability) engineers to eliminate potential reliability risks, reduce assembly defects, and ensure consistent quality during mass production.

3. The Advanced Manufacturing Process at PCBBUY

The medical PCBA manufacturing process at PCBBUY follows a structured workflow that ensures precision at every step:

Step 1: Solder Paste Printing

Through high-precision stencil printers, solder paste is precisely deposited on PCB pads with a high degree of accuracy that allows the formation of reliable solder joints in relation to fine-pitch components.

Step 2: Component Placement

With pick-and-place machines that are fully automated and can place components as small as 0201, our SMT assembly lines can place the components. All placements are checked with the help of AOI (Automated Optical Inspection) in order to guarantee zero misalignment.

Step 3: Reflow Soldering

Its soldering profile is optimized to sensitive medical grade. Our reflow ovens ensure a very controlled thermal control to avoid stress or oxidation when soldering.

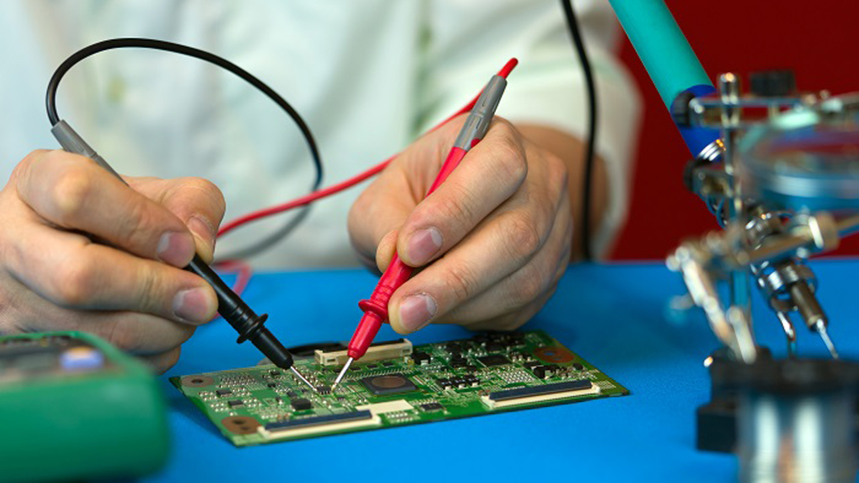

Step 4: Inspection and Operational Testing.

Every medical PCBA will be X-rayed (in case of BGA and fine-pitch components), ICT (In-Circuit Testing) and FCT (Functional Circuit Testing). This guarantees structural integrity as well as signal accuracy under simulated conditions of medical devices.

Step 5: Conformal Cleaning and Coating.

PCBBUY uses conformal coating to resist moisture, chemicals, and dust to ensure that the hospital and laboratory meet hygienic requirements. Ultrasonic cleaning also eliminates any traces that may give it biocompatible issues.

4. Why Choose PCBBUY for Your Medical PCBA Projects

When it comes to medical electronics, trust and precision define the difference between a standard manufacturer and a true engineering partner. Here’s why global clients choose PCBBUY:

-

Certified Quality Systems: ISO 9001, ISO 13485, and IPC-A-610 Class 3 compliance.

-

Custom Solutions: From prototype to mass production, tailored to your unique medical design.

-

Traceability and Documentation: Full material and process traceability for every batch.

-

Rapid Prototyping: Quick turnaround for R&D testing and validation.

-

Comprehensive Testing: 100% electrical testing and optical verification before shipment.

PCBBUY’s production lines integrate automated SMT assembly, wave soldering, and selective soldering, ensuring stable quality for both rigid and rigid-flex PCBA used in compact medical systems.

5. The Future of Medical PCBA and PCBBUY’s Commitment

As healthcare evolves toward miniaturized, smart, and wearable medical devices, the demand for high-density, flexible, and biocompatible PCBA continues to grow.

At PCBBUY, we’re constantly upgrading our processes to support next-generation designs—such as HDI PCBs for implantable devices, flex-rigid PCBAs for surgical tools, and IoT-based patient monitoring systems.

By integrating AI-driven inspection, automated data tracking, and green manufacturing, PCBBUY remains at the forefront of sustainable medical electronics production.

Conclusion

The safety of any given medical equipment is basically determined by the circuitry they are built on. PCBBUY offers medical PCBA solutions that are trusted by healthcare innovators all over the globe, and it is enabled by the use of innovative design validation, accurate assembly, and stringent quality assurance measures.

Do you want a partner who can turn complicated designs into life-saving electronic devices? PCBBUY will make your vision come true safely, accurately and efficiently.

FAQ About Medical PCBA

1. What is medical PCBA?

Medical PCBA refers to the printed circuit board assembly used in medical devices such as ECG monitors, imaging systems, and wearable health trackers. It involves assembling electronic components with high precision and reliability to meet strict medical standards.

2. What makes medical PCBA different from regular PCB assembly?

Compared to standard PCB assembly, medical PCBA must comply with higher safety, cleanliness, and quality requirements, including ISO 13485 certification, biocompatible materials, and 100% functional testing.

3. Does PCBBUY provide customized medical PCBA solutions?

Yes. PCBBUY offers customized medical PCBA services, from material selection and DFM optimization to final assembly and testing, ensuring each product meets your medical device’s unique design and regulatory requirements.

4. How does PCBBUY ensure the quality of medical PCBA?

PCBBUY performs full-process quality control including AOI, X-ray inspection, ICT/FCT testing, and conformal coating. All medical PCBA products are manufactured under ISO 9001 and ISO 13485-certified facilities.

5. Can PCBBUY handle low-volume medical PCBA prototypes?

Absolutely. PCBBUY provides rapid prototyping and small-batch manufacturing for medical PCBA, helping clients validate new designs quickly before moving to mass production.

Industry Category