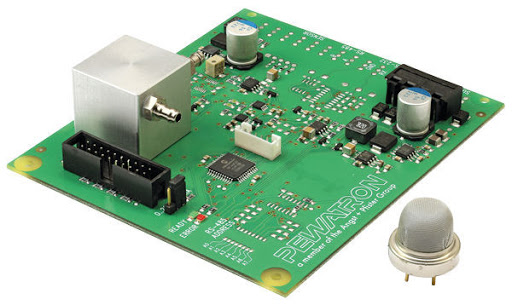

Oxygen machine circuit board

By:PCBBUY 04/28/2021 10:55

Oxygen machines — also called oxygen generators — for industrial use take air as the raw material, requiring no additional auxiliary materials. They adopt the pressure swing adsorption (PSA) method to separate oxygen from nitrogen in the air and filter out harmful substances, thereby supplying oxygen with a purity of 90%. This meets various industrial needs, and the installation and operation costs are lower than those of bottled or liquefied oxygen.

Household oxygen machines produce oxygen-enriched air by filtering nitrogen molecules from the air. They feature a compact size and low power consumption, but the generated oxygen concentration is relatively low — while this means they don’t deliver effective therapeutic results, they are ideal for health maintenance purposes. With practical and accessible benefits, they are well-suited for home use but not for industrial oxygen production. Such machines are also commonly used in vehicle-mounted oxygen generators.

Working principle of oxygen machine

Oxygen generators adopt molecular sieve technology, which ensures stable oxygen concentration and fully meets the needs of oxygen users. Except for oxygen cylinders, the oxygen generation principles of other oxygen-producing equipment can be roughly categorized into four types:

Molecular sieve oxygen generator

The molecular sieve oxygen generator adopts advanced PSA (pressure swing adsorption) air separation oxygen production technology, which is based on the difference in the adsorption capacity of oxygen and nitrogen in the air by the attractant (zeolite molecular sieve) to achieve the separation of oxygen and nitrogen, which can be directly from the air Extracting high-purity oxygen is the only oxygen generator with international and national standards. The new machine's oxygen concentration at the factory should be 90%. It must have a cumulative timing function and an oxygen concentration status monitoring system. The sound produced at the maximum flow rate does not exceed 60 decibels.

Electronic oxygen generator

The electronic oxygen generator uses the process of oxidation and reduction of oxygen in the air in the solution. It does not produce dangerous hydrogen like electrolyzed water. The operation is relatively quiet, and the requirements during handling and use are very strict. Never tilt or turn it upside down, otherwise the solution will flow into the oxygen delivery tube and be sprayed into the nasal cavity, which will cause serious damage to the user.

Oxygen-rich membrane oxygen generator

Oxygen-enriched membrane oxygen generators produce oxygen-enriched air through the filtration of nitrogen molecules in the air by the membrane, which has the advantages of small volume and small power consumption, but the generated oxygen concentration is low and does not have a good therapeutic effect. Car oxygen generator.

Chemical oxygen generator

The chemical agent oxygen generator uses reasonable chemical formulas to generate oxygen in specific occasions through chemical reactions between the agents, which can meet the urgent needs of some consumers, but the equipment is simple, the operation is cumbersome, the use cost is high, and it cannot be used continuously. Not suitable for long-term home use.

Industry Category