PCB Assembly Standards – Why They Matter and How PCBBUY Delivers

By:PCBBUY 09/30/2025 17:26

Introduction

When it comes to electronics, the small details make the biggest difference. A tiny solder joint that doesn’t meet standards can affect the entire device. That’s why pcb assembly standards exist—they ensure every circuit board is reliable, durable, and safe to use.

At PCBBUY, we believe that meeting international standards isn’t just about passing inspections—it’s about building trust with every customer. Whether you’re ordering a prototype or preparing for mass production, our team follows strict processes to guarantee your boards perform exactly as expected.

What Do PCB Assembly Standards Actually Mean?

Simply put, pcb assembly standards are the rules that manufacturers follow to keep quality consistent. They cover everything from the solder paste we use, to how components are placed, to the tests performed before shipping.

Some of the most important standards we follow at PCBBUY include:

-

IPC-A-610 – The “gold standard” for PCB assembly quality, covering solder joints, component alignment, and cleanliness.

-

ISO 9001 – A global certification that shows we have strong quality management systems.

-

RoHS/REACH Compliance – Ensuring our boards are environmentally friendly and free from hazardous materials.

For customers, these standards mean peace of mind: your boards are built for reliability and global compliance.

Why PCB Assembly Standards Are Critical

You might wonder: do these standards really matter? The answer is yes—absolutely. Without strict guidelines, even small variations can cause:

-

Higher failure rates in the field

-

Costly delays from rework and repairs

-

Shorter product lifespan

By following pcb assembly standards, manufacturers like PCBBUY can guarantee:

-

Consistency from batch to batch

-

Reliability in demanding applications

-

Compliance with international requirements (so your product can enter global markets smoothly)

How PCBBUY Applies PCB Assembly Standards Every Day

At PCBBUY, we don’t just “check boxes”—we integrate pcb assembly standards into every part of our process.

1. Materials

We carefully select substrates, solder paste, and components from verified suppliers. Everything is RoHS-compliant and traceable.

2. Assembly Process

-

SMT Assembly with fully automated pick-and-place machines for precise component mounting.

-

Reflow Soldering with optimized heat profiles to create strong solder joints.

-

Wave Soldering for through-hole parts, meeting IPC guidelines.

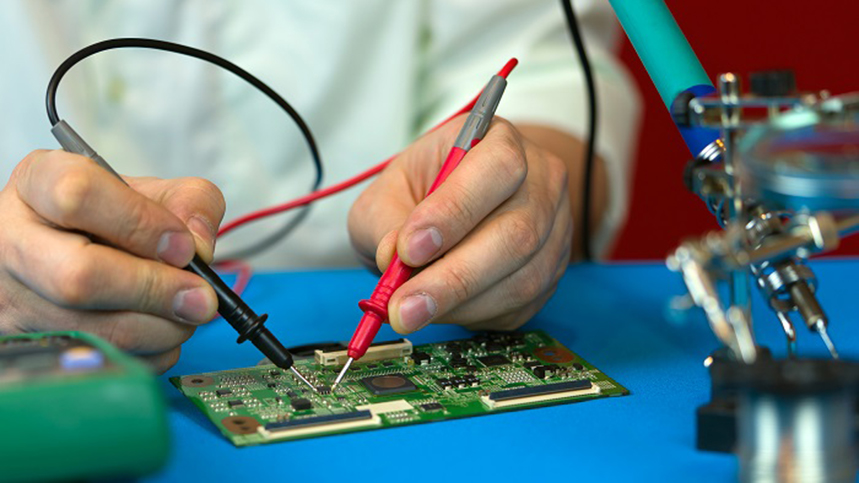

3. Testing and Inspection

Every board goes through:

-

AOI (Automated Optical Inspection) for component placement accuracy.

-

X-ray testing for hidden joints, like in BGA packages.

-

ICT and Functional Testing to verify performance.

4. Packaging and Delivery

Boards are packaged with anti-static and moisture-proof protection so they arrive safely, no matter where in the world they’re shipped.

PCBBUY’s Commitment to Quality

Here’s what sets PCBBUY apart in meeting pcb assembly standards:

-

Every operator is IPC-certified, trained to the highest international standards.

-

Each board goes through 100% E-Test and AOI before leaving our factory.

-

We use state-of-the-art equipment, including advanced SMT lines and reflow ovens.

-

A dedicated quality management team oversees every production step.

For example, when a client recently needed BGA assembly for HDI boards, we followed strict IPC guidelines. The result? Boards that passed rigorous stress tests with zero defects—saving the client both time and cost.

Why Choose PCBBUY?

In a crowded market, many suppliers claim “quality,” but at PCBBUY we prove it through our strict commitment to pcb assembly standards. With us, you get:

-

Consistent, reliable results

-

The flexibility to handle both prototypes and large-scale runs

-

Experience with complex projects like HDI, multilayer PCBs, and BGA assembly

-

Full-service support—from design to testing to shipping

Conclusion

PCB assembly standards aren’t just about rules—they’re about trust. By choosing PCBBUY, you’re choosing a partner who takes quality seriously and delivers boards you can rely on.

Whether you’re building the next big consumer product or a specialized industrial device, PCBBUY ensures that every board meets international standards—so your business can move forward with confidence.

FAQ on PCB Assembly Standards

1. What are the most important pcb assembly standards I should know about?

The key standards include IPC-A-610 (quality of electronic assemblies), ISO 9001 (quality management), and RoHS compliance (environmental safety). These ensure your PCBs are reliable and globally accepted.

2. Why should I care if my supplier follows pcb assembly standards?

When a manufacturer follows strict standards, you can expect consistent quality, fewer defects, and long-term reliability of your product. It also ensures compliance with international regulations, making global distribution easier.

3. Does PCBBUY follow international pcb assembly standards?

Yes. PCBBUY integrates IPC, ISO, and RoHS guidelines into every production step, from materials sourcing to final inspection. This guarantees high-quality boards that meet global market requirements.

Industry Category