PCB Conformal Coating Types

By:PCBBUY 09/04/2021 09:31

Conformal coating is a thin film of protective insulating material applied to a fully assembled circuit board. It is made of a non-conductive material, and can cover the entire board depending on the needs of the PCB and what environment it will be operating in. It will cover and protect exposed areas of metal such as traces that aren’t already covered with solder mask, component leads, and solder joints.

Conformal coatings will even increase the dielectric strength of a board allowing for reduced spacing between circuits in more compact and dense PCB layouts. In this passage, we are going to provide you everything about PCB conformal coating, please check and read the content below for more information.

What are the advantages of PCB conformal coating?

· Insulating properties allow a reduction in PCB conductor spacing of over 80%

· Can help eliminate the need for complex, sophisticated enclosures

· Light weight

· Completely protect the assembly against chemical and corrosive attack

· Eliminate potential performance degradation due to environmental hazards

· Minimize environmental stress on a PCB assembly

What are the main applications of PCB conformal coating?

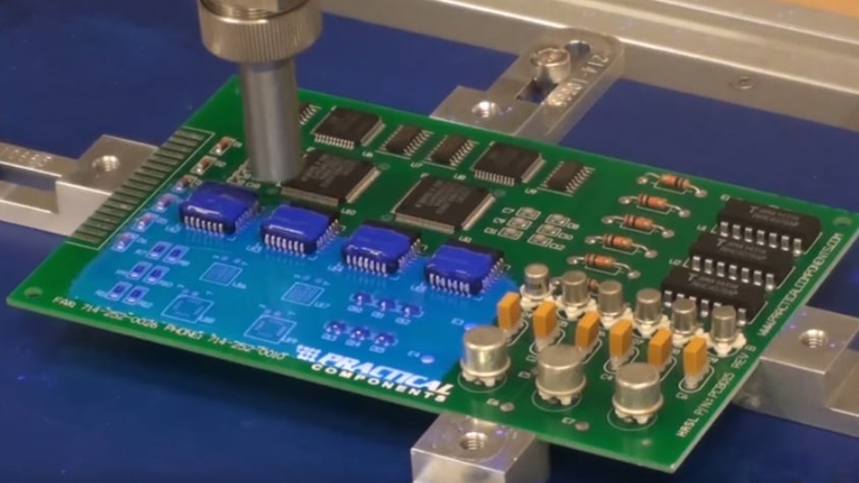

When you have your circuit board coated, there are many different ways that the conformal coating can be applied:

· Dipping: For boards that are in high volume production runs, dipping is the usual method of applying a conformal coat. Dipping will coat both sides of the board, so PCBs that have specific areas that either need or don’t need coating will have to use another method.

· Automated spraying: This method is also used for production runs. The circuit boards are run through the process on a conveyor belt, and reciprocating spray heads will apply a consistent coating on the board.

· Selective coating: This is a variation of the automated spraying, but programmable spray heads are used instead of reciprocating. This allows for boards with unique requirements to have specific areas programmed for applying the conformal coating.

· Manual spraying: For technicians working on a board, manually spraying conformal coating with a spray gun or an aerosol can is the fastest approach. This is a labor intensive operation used in low production runs, although it lends itself well for boards that have unique requirements. Those areas can be masked off to prevent the conformal coating from applied there.

· Brushed: This is the slowest method of applying conformal coating, and is usually done when a board is being reworked or repaired and the coating has been removed in specific areas. Brushing the coating on however could result in variations of the application as it is not as consistent as spraying the coating.

What are the types of PCB conformal coating?

There are different types of conformal coating materials or chemistries that are used depending on what the specific needs of your PCB QUOTE are. Here are the more common ones in use:

Acrylic Resin (AR):

These coatings are the most commonly used conformal coatings because they are economical and will protect against a broad range of contamination. They are not the highest level of protection, however, and do not protect against solvents or solvent vapors. They have a very high level of dielectric strength and can be easily removed, making PCB rework very practical.

Silicone Resin (SR):

Silicon coatings have a very wide temperature range of protection and are very chemical, moisture, and salt spray resistant. Due to its rubbery nature, it isn’t abrasion-resistant, but it does hold up very well against vibration stresses. These coatings are often used for environments with high humidity but are difficult to remove and require specialized solvents for PCB rework.

Urethane Resin (UR):

These coatings are excellent at resisting abrasion as well as being moisture and chemical resistant. Because of these qualities, urethane coatings are often used in aerospace applications due to their ability to resist fuel vapors. On the other hand, like silicone, this coating is very difficult to remove and requires specialized solvents for PCB rework.

Epoxy Resin (ER):

Epoxy is somewhat different from the other conformal coatings in that it used to completely encapsulate the electronics in a solid layer of material. This provides excellent protection against humidity, abrasion, and chemical contamination. The hard coating, however, is almost impossible to remove once it is cured.

Industry Category