PCB Crosstalk Calculator

By:PCBBUY 09/03/2021 10:17

When there is crosstalk on your circuit board, the board may not work correctly, and you could lose important information there too. To avoid this it is in the best interest of PCB designer to find ways to eliminate the potential of crosstalk in their designs.

In this passage, we will tell you everything about it and please check and read the content we prepare for more information.

What are the issues of PCB crosstalk?

Too much activity in a circuit board can make the transmission of a signal difficult. Think of two traces on a circuit board running together side-by-side. If the signal of one trace is “louder” with more amplitude than the signal of the other, it could over-power that other trace. And just as it can be difficult in a noisy room to keep your own thoughts straight when trying to speak, the “victim” trace on a PCB will be similarly influenced by the louder signal. The problem then is that the victim signal will start behaving like the aggressor signal instead of behaving the way that it is supposed to.

Crosstalk is defined as the unintentional electromagnetic coupling between traces on a printed circuit board. The overpowering of one signal in a trace by another one is the result of this coupling even though the two traces are not in physical contact with each other. This can happen on a PCB that has acceptable trace spacing for manufacturing but where the spacing is not acceptable for crosstalk.

In addition to the potential for crosstalk between two traces that are side-by-side on the same layer, there is an even greater risk for traces that are running parallel to each other vertically between two layers. This effect is known as broadside coupling and happens because the two signal layers are separated by only a very small thickness of core material. This distance is often less than the spacing between two traces on the same layer.

Where to find the crosstalk in PCB design?

Very simply, crosstalk can occur between any two conductors that carry signals in your PCB quote. This includes digital and analog nets. When crosstalk occurs, a signal on one conductor (the aggressor net) will couple a portion of itself as a new signal on a nearby conductor (the victim net). Digital and analog signals can induce crosstalk in different ways.

Crosstalk couples between signal nets in two ways, depending on the dominant type of parasitics that exist between two or more traces:

Capacitive crosstalk

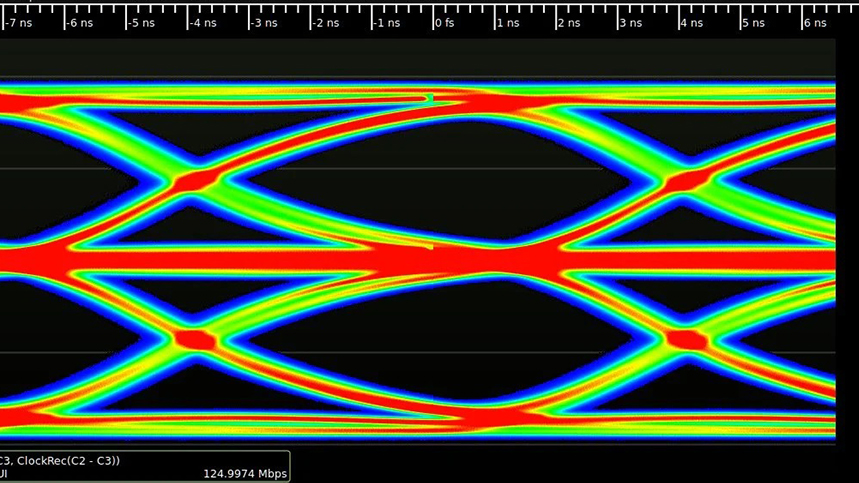

This type of crosstalk occurs due to broadside parasitic and ground-coupled capacitance between two conductors. The magnitude of capacitive crosstalk is proportional to the parasitic capacitance between the two conductors. For analog signals, the strength of capacitively coupled signals increases with frequency, so this type of crosstalk can dominate in high frequency nets or when digital signals have very fast edge rates. Digital signals can induce capacitive crosstalk with transient ringing during and after switching.

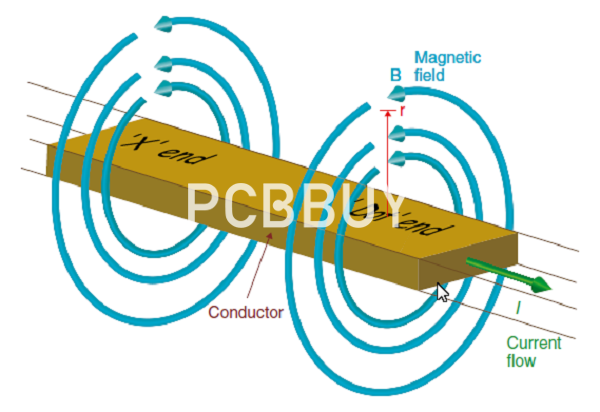

Inductive crosstalk

This type of crosstalk occurs due to parasitic inductance between two loops of conductors. The magnitude of an inductive crosstalk signal from an analog aggressor signal is proportional to the rate at which the current in the aggressor trace changes (i.e., proportional to signal frequency). Digital signals can induce inductive crosstalk during switching, during which time the magnetic field emitted from the signal induces a changing flux in the victim net.

Inductive and capacitive crosstalk depends on the mutual inductance and mutual capacitance between two traces, respectively. These terms are determined entirely by the magnetic and electrostatic interactions between different conductors, as well as how these conductors are arranged in space. What this means is that you need to analyze crosstalk in a post-layout simulation; you can’t do anything to spot crosstalk from your schematics.

How to avoid crosstalk in PCB?

So now that you understand a bit about the physics behind crosstalk, how do you guard against it in your PCB designs? The key thing to take away from crosstalk is that it while it occurs everywhere, it’s the largest between parallel signal lines.

The best way to eliminate crosstalk is to exploit the very parallelism that leads to its creation by closely coupling the return path to ground to your high-speed signals. Since the return path is equal in magnitude but opposite in direction, the fields cancel out and reduce crosstalk.

Another way to ensure signal integrity is to use differential signaling, where two voltage lines equal in magnitude but opposite in polarity are used to create a single high-speed data signal. Since the actual data signal is taken as a difference between the voltages of the two voltage lines at the receiver, and because electromagnetic noise tends to affect both lines equally, the signal itself remains perceptible even in the presence of external noise.

· Here’s a quick summary of PCB routing tips for reducing crosstalk:

· Reduce the length that two lines are allowed to run in parallel.

· Be sure to have solid return paths where possible.

· Use differential signaling where applicable.

· Use guard traces with vias connected to ground.

· Keep high-speed signals, especially clock signals, isolated from other traces where possible.

· Keep traces in adjacent layers perpendicular to each other.

Industry Category