PCB Design for Assembly Guidelines

By:PCBBUY 09/07/2021 09:02

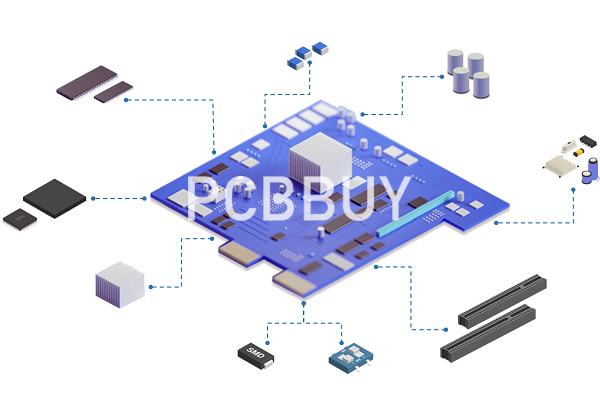

After a PCB design is submitted and approved—be it flex, high density interconnect (HDI), or otherwise—it is fabricated. A PCB design may seem perfectly acceptable when viewed in isolation, but certain design decisions may make assembly difficult later on.

In order for the PCB assembly process to flow smoothly—and, therefore, for the PCB production as a whole to progress effectively—the assembly vendor needs to have the requisite components on hand as soon as the boards arrive.

In this passage, we will tell you everything about the considerations about PCB design for assembly. If you are looking for the topic please check and read the content we provide for more information.

If you want to order PCB product, please check and custom your order online.

What is the importance of PCB design for assembly?

When it comes to anything you do—whether it’s cutting the grass or cooking a meal—we usually want the end result to turn out the way we planned. The same can be said when designing a PCB—we should worry first about getting it to work first, right? The answer here is both yes and no.

Not only do we need our PCBs to work the way that we’ve designed them too, but those boards must be manufacturable for a reasonable price as well. There are several factors that can contribute to a board not being considered manufacturable. Here are the main categories of problems:

Components

Parts that are unique or not readily available will have higher costs attached to them. Also if the lead times on some parts cause delays in the board build, that will add to the expense as well.

Placement

How you place your parts can affect how the board is manufactured and drive up costs. Even simple things such as how a component is rotated can affect its solderability.

Layout

Your PCB design will usually connect to other boards or interfaces. If these considerations haven’t been accounted for up front, it could add to the expense of manufacturing the entire system.

What are the guidelines of PCB design for assembly?

Working together with your CM before and during your design will give you both the best opportunity to be successful in building your PCBA. Your CM should review your design to help you to make the best component selections to avoid the cost and delay of EOL parts. They should also work with you on your component placement to enhance your design’s manufacturability. By helping you to design your board according to good design for assembly practices, your design will enjoy better yields, costs, and cycle times.

The following guidelines are helpful during the design process in ensuring the efficient and easy assembly of the board and other components.

Use standard and common components

Should ensure that the components you plan to use are readily available. Also, you should validate their continued production to avoid having components whose end of life (EOL) is approaching as it will minimize delays in the future. Standard and readily available components result in reduced costs, higher quality, and lower inventories. Unique parts lead to increased costs and high chances of poor quality.

Component Spacing Rules

You should design the board, ensuring that you carefully place the components in a way that they are not too close or too far from each other. No component should overlap with each other. A component placed too close to another cause issues that may require redesigning. To prevent spacing issues, you should ensure that you design your footprint in a way that allows enough gap between the boundaries of each component. The below table shows how much space should be left around each component for different types of IC packages.

Updated BOM

The bill of materials (BOM) is crucial and it should not have any issues as it leads to project delays. You should review the BOM whenever there are changes in the design. Addition or change in the components should be updated with the correct component number, description, and values.

Follow Datasheet Strictly for Footprint: The recommendations help in creating accurate footprints and identifications that prevent pad mismatches. Ignoring these recommendation lead to incorrect footprint, this may require full redesign and re-fabrication of the boards.

What are the considerations of PCB design for assembly?

The primary objective of DfA is ease-of-assembly. Moving towards that objective requires an emphasis on eliminating complexity and reducing uncertainty. An emphasis on eliminating complexity pushes design teams to think about reducing the number of components used for a PCB and to consider the type of components selected. For example, design teams may determine that selecting resistor or capacitor arrays—rather than groups of single passive components—saves board space and lowers costs.

The “back-to-basics” approach to DfA also prompts design teams to consider—and perhaps reconsider—the use of fragile, heavy, or bulky components. Heavy and bulky transformers, power resistors, and mechanical assemblies drive shipping costs higher and require specific fabrication measures to ensure that the physical design of the board supports the components.

Industry Category