PCB Manufacturing Challenges and How They Are Addressed in Modern PCB Production Introduction

By:PCBBUY 12/29/2025 14:47

As electronic products continue to evolve toward higher performance, smaller size, and greater reliability, PCB manufacturing has become increasingly complex.

Designers and engineers are now facing a wide range of pcb manufacturing challenges that did not exist in traditional PCB production. Understanding these challenges is essential not only for PCB designers, but also for customers selecting a reliable manufacturing partner.

The Growing Complexity of PCB Manufacturing

Modern PCBs are no longer simple interconnection platforms. They often involve:

-

High-density interconnect (HDI) structures

-

Fine line and fine pitch designs

-

Multilayer stackups with tight tolerances

-

Advanced materials for high-speed or high-temperature applications

Each of these factors introduces new pcb manufacturing challenge points that must be controlled throughout the production process.

Common PCB Manufacturing Challenges

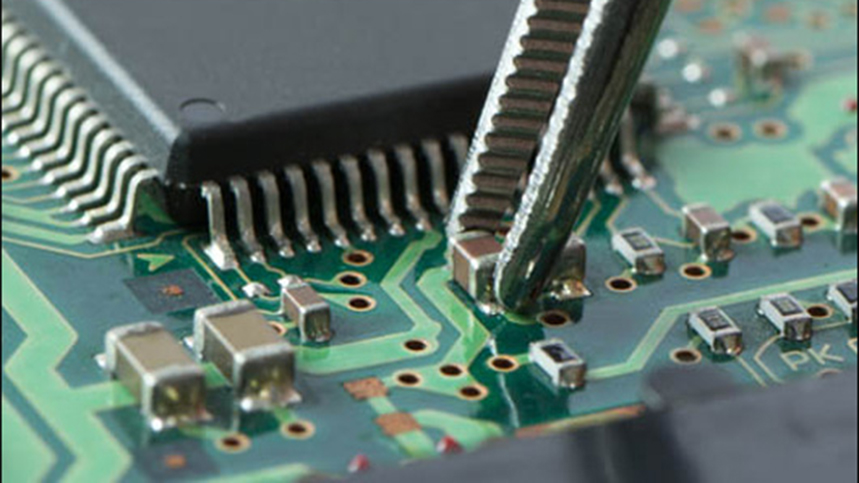

High-Density and Fine-Line Processing

As trace width and spacing continue to shrink, maintaining etching accuracy becomes more difficult.

Small variations in imaging, exposure, or etching can lead to open circuits or short circuits.

Fine-line processing is one of the most common pcb manufacturing challenges in HDI and advanced multilayer boards.

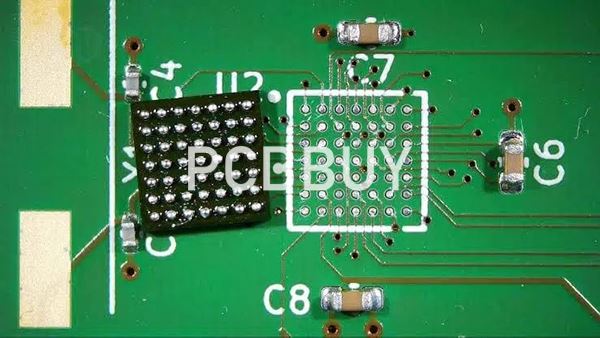

Drilling Accuracy and Aspect Ratio Control

High layer counts and thick boards often require deep drilling with small hole diameters.

This creates challenges in:

-

Hole wall quality

-

Drill deviation

-

Copper plating uniformity

High aspect ratio holes require strict process control to ensure reliable electrical connections.

Multilayer Alignment and Lamination Stability

Layer-to-layer registration is critical in multilayer PCB manufacturing. Misalignment during lamination can affect via integrity, impedance control, and overall board reliability. Controlling resin flow, pressure distribution, and thermal profiles is a major pcb manufacturing challenge in multilayer production.

Copper Thickness and Plating Uniformity

Consistent copper thickness is essential for current carrying capacity and long-term reliability.

Uneven plating can lead to weak vias, excessive resistance, or reliability failures during thermal cycling. This challenge becomes more severe in boards with mixed via sizes or high copper requirements.

Material Compatibility and Process Adaptation

Advanced PCB designs often use special materials such as:

-

High-Tg laminates

-

Low-loss or high-frequency materials

-

Hybrid material stackups

Each material behaves differently during drilling, lamination, and thermal processing, adding complexity to manufacturing.

Design-Related PCB Manufacturing Challenges

Not all pcb manufacturing challenges originate on the factory floor.

Many issues are introduced during the design stage, including:

-

Aggressive line width or spacing

-

Insufficient copper-to-edge clearance

-

Improper via structures

-

Lack of consideration for depanelization methods

Without proper DFM (Design for Manufacturability) review, these risks may only be discovered after production begins.

How Manufacturing Capability Helps Overcome PCB Manufacturing Challenges?

Process Control and Equipment Precision

Advanced manufacturing equipment allows tighter control over imaging, drilling, plating, and lamination processes. Stable equipment performance is essential to reduce variation and improve yield.

Standardized Production and Inspection

Standard operating procedures and in-process inspections help identify defects early.

This reduces rework and ensures consistent quality from prototype to mass production.

Engineering Support and DFM Review

Early-stage DFM review plays a key role in minimizing pcb manufacturing challenge risks. Engineering feedback before production helps balance performance, reliability, and manufacturability.

PCBBUY’s Approach to PCB Manufacturing Challenges

PCBBUY focuses on engineering-driven PCB manufacturing rather than price-driven production.

By combining process control, experienced engineers, and structured DFM review, PCBBUY helps customers manage complex PCB manufacturing requirements.

Key strengths include:

-

Experience with multilayer and HDI PCB production

-

Stable control of drilling, plating, and lamination processes

-

Capability to support both prototype and volume manufacturing

-

Export-oriented quality standards for global customers

This approach allows potential issues to be identified and resolved before they affect delivery or reliability.

Reducing PCB Manufacturing Challenges Through Collaboration

Customers can reduce pcb manufacturing challenge risks by:

-

Designing with manufacturability in mind

-

Providing complete fabrication notes and requirements

-

Engaging manufacturers early during the design phase

A collaborative approach leads to higher yield, better reliability, and shorter development cycles.

Conclusion

PCB manufacturing challenges are an inevitable result of advancing technology and increasing design complexity.

However, with proper design practices and a capable manufacturing partner, these challenges can be effectively managed. By combining engineering expertise, process control, and DFM support, PCBBUY helps customers navigate pcb manufacturing challenge issues and achieve reliable PCB production.

Industry Category