PCB Plugged Vias of Advanced Manufacturing Process

By:PCBBUY 08/25/2025 14:34

Introduction: What Are PCB Plugged Vias?

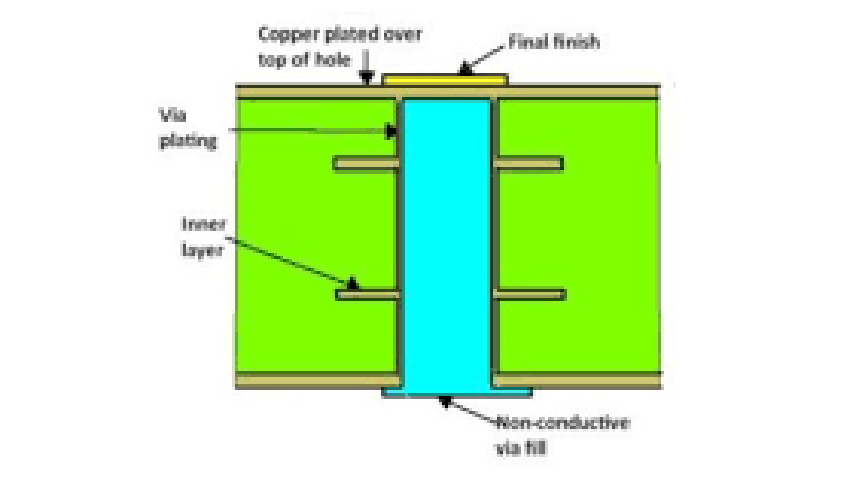

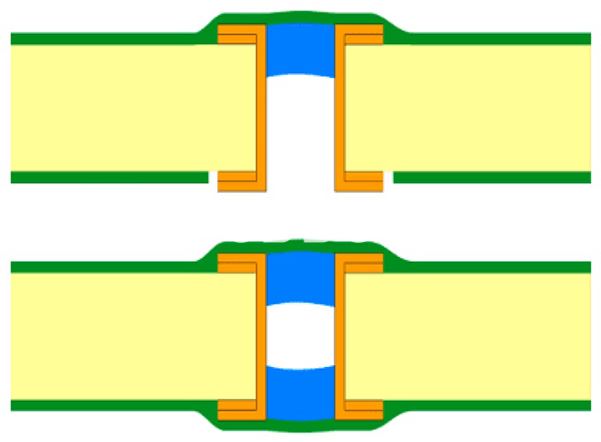

In modern PCB design, pcb plugged vias have become a critical technology to ensure reliability, flatness, and high electrical performance. A plugged via refers to a plated-through hole that is filled with resin, epoxy, or solder mask to prevent solder leakage and improve the overall performance of the board. Unlike tenting vias, which are only covered by solder mask, plugged vias provide superior mechanical strength and ensure stability in high-density PCB assemblies, especially under BGA (Ball Grid Array) and CSP (Chip Scale Package) components.

At PCBBUY, we specialize in manufacturing high-quality pcb plugged vias that meet IPC and international standards, offering customers both cost-effective and high-performance solutions for advanced electronics.

Why PCB Plugged Vias Are Essential in Modern PCB Design

The demand for smaller, faster, and more reliable electronic devices has increased the importance of pcb plugged vias in circuit design. Their advantages include:

-

Prevention of solder wicking: Ensures stable solder joints under BGA pads.

-

Improved insulation reliability: Prevents contamination and oxidation inside vias.

-

Enhanced signal integrity: Reduces crosstalk and impedance fluctuations in high-speed circuits.

-

Mechanical strength: Increases PCB durability, especially in automotive and aerospace applications.

PCB Plugged Vias Manufacturing Process at PCBBUY

At PCBBUY, we follow a precise, multi-step process to manufacture pcb plugged vias that meet strict quality requirements:

-

Design Analysis – Engineers review via diameter, location, and filling requirements to ensure manufacturability.

-

Drilling & Copper Plating – High-precision drilling and uniform copper plating guarantee stable conductivity and smooth hole walls.

-

Resin/Epoxy Filling – Holes are filled using advanced vacuum technology to ensure complete plugging, avoiding voids and air gaps.

-

Planarization & Grinding – Excess resin is ground flat to achieve a smooth surface, ideal for fine-pitch BGA assembly.

-

Solder Mask Application – A protective solder mask is applied to prevent oxidation and leakage.

-

AOI and X-ray Inspection – Automated Optical Inspection (AOI), X-ray, and cross-section tests confirm the quality and reliability of plugged vias.

This detailed process guarantees that every pcb plugged via manufactured at PCBBUY meets international IPC-A-600 and IPC-6012 standards.

Industry Standards for PCB Plugged Vias

PCBBUY’s pcb plugged vias are produced in compliance with IPC standards and internal quality guidelines. According to our process capability:

-

Solder Mask Plugged Hole Diameter ≤0.45mm – Holes smaller than or equal to 0.45mm can be fully filled.

-

For holes ≥0.45mm – Oil plugging may not be completely full by default, but PCBBUY applies advanced epoxy resin plugging to ensure stability when required.

This ensures that all plugged vias maintain no light leakage, no voids, and a reliable electrical connection.

PCB Plugged Vias vs. Other Via Protection Methods

|

Via Type |

Process |

Advantages |

Limitations |

|

Plugged Vias |

Resin/Epoxy fille d |

Excellent flatness, ideal for BGA |

Higher cost, more complex process |

|

Tenting Vias |

Covered with solder mask |

Cost-effective, prevents oxidation |

Not suitable for fine-pitch BGA |

|

Via-in-Pad (Copper Capped) |

Copper-filled & plated over |

Best thermal & electrical performance |

Most expensive, complex process |

This comparison highlights why pcb plugged vias are the best balance between performance and cost for advanced electronics.

Applications of PCB Plugged Vias

PCBBUY supplies pcb plugged vias for a wide range of industries and applications, including:

-

Smartphones & tablets (HDI multilayer boards).

-

BGA and CSP packaging (fine-pitch assembly).

-

Automotive electronics (vibration and reliability requirements).

-

Aerospace and medical devices (extreme reliability conditions).

PCBBUY’s Advantage in PCB Plugged Vias Manufacturing

What sets PCBBUY apart is our combination of advanced technology and strict quality management:

-

Advanced resin filling and grinding equipment for stable and consistent via plugging.

-

High-precision AOI, X-ray, and cross-section testing for defect-free production.

-

Flexible production capacity from prototype to large-scale manufacturing.

-

Expertise in HDI, high-Tg laminates, and automotive-grade PCBs.

By controlling every detail of the process, PCBBUY delivers pcb plugged vias that provide excellent flatness, durability, and electrical reliability.

Conclusion

PCB plugged vias are essential for modern high-density PCB design, especially under BGA and HDI applications. They ensure solder joint stability, improve electrical performance, and extend PCB lifespan.

At PCBBUY, we combine advanced equipment, experienced engineers, and strict IPC-compliant quality standards to provide customers with reliable pcb plugged vias for all applications. Whether you need prototypes or volume production, PCBBUY is your trusted partner for high-quality PCB manufacturing.

Industry Category