PCB Rectangle Slot Manufacturing Guidelines

By:PCBBUY 11/24/2025 14:12

A PCB rectangle slot is a non-circular board opening produced through routing, drilling, or laser machining. It plays a critical role in mechanical integration and component mounting. For manufacturers, the slot’s dimensional accuracy, plating uniformity, and positional tolerance directly affect assembly reliability.

This document provides a detailed engineering view of rectangle slot types, fabrication methods, and PCBBUY’s process capabilities.

At PCBBUY, we work with rectangle slots on a daily basis, helping customers achieve the exact shape, tolerance, and plating quality required for their applications. This article introduces what a rectangle slot is, how it is manufactured, and how to design it correctly for a successful production.

1. What Is a PCB Rectangle Slot?

A PCB rectangle slot is a non-circular opening in the PCB, typically long and narrow. It can be used for:

-

USB / HDMI / Type-C connectors

-

Metal brackets or shields

-

Card-locking structures

-

Power terminals

-

Mechanical parts that require precise alignment

Rectangle slots can be made as NPTH (non-plated) or PTH (plated through-hole) slots depending on their function.

2. Types of PCB Rectangle Slots

● NPTH Rectangle Slot

An NPTH rectangle slot is used for purely mechanical purposes.

It is created through CNC routing and does not require copper plating.

● PTH Rectangle Slot

A plated rectangle slot has copper plating on its inner walls, allowing it to carry electrical current or serve as a connector mounting hole.

Compared with NPTH, it is more technically demanding due to tighter copper thickness requirements.

● Laser-Cut Rectangle Slot (HDI / Thin Boards)

PCBBUY uses high-precision laser cutting for ultra-thin boards, flex-rigid boards, or HDI designs requiring micro-slots.

3. How PCB Rectangle Slots Are Manufactured at PCBBUY

PCBBUY combines several techniques to ensure tight tolerances and stable quality:

● CNC Routing

-

High-precision spindle

-

Minimum routing width depends on tool size

-

Stable dimensional consistency for mass production

● Drill-and-Mill Composite Process

We drill the slot endpoints first and then mill the rectangular shape.

This improves accuracy and reduces tool wear.

● Electroplating for PTH Slots

We control:

-

Copper thickness

-

Sidewall uniformity

-

Clean, burr-free edges

This is especially important for connectors that need strong mechanical anchoring.

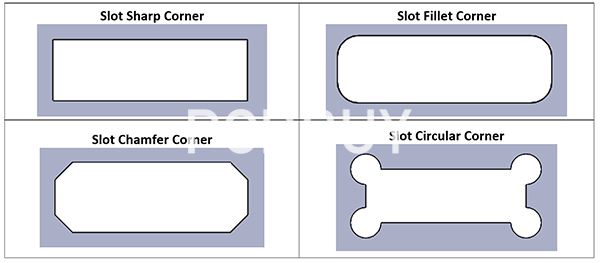

4. PCB Rectangle Slot Design Guidelines

To avoid production issues, PCBBUY advises the following design principles:

-

Recommended minimum slot width: based on tool diameter

-

Avoid sharp 90° internal corners (due to round milling bits)

-

Clearly mark PTH or NPTH in your files

-

Include dimensions and tolerance (e.g., ±0.05 mm)

-

Confirm plating requirement during order submission

Our engineering team performs free DFM checks to validate slot geometry before manufacturing.

5. Typical Applications

Rectangle slots are widely used in:

-

Consumer electronics

-

Industrial controllers

-

Power equipment

-

Automotive electronics

-

Communication devices

PCBBUY supports projects from prototype to large-scale production.

6. Why Choose PCBBUY for PCB Rectangle Slot Fabrication?

-

CNC routing precision up to ±0.05 mm

-

Experience with FR4, aluminum PCB, copper-based PCB, and HDI

-

Reliable copper plating for PTH rectangle slots

-

Full AOI inspection + dimensional measurement before shipping

-

Fast quotation and professional engineering feedback

We help customers reduce errors, avoid redesigns, and accelerate their time-to-market.

7. How to Specify PCB Rectangle Slots in Your Files

To ensure smooth production, indicate:

-

Slot width and length

-

NPTH or PTH

-

Tolerance

-

Shape outline on mechanical layer

-

Drilling notes if needed

PCBBUY engineers will confirm the details before fabrication.

FAQ

1. What determines whether a slot should be PTH or NPTH?

If the component requires electrical conductivity or mechanical anchoring, use PTH; otherwise NPTH is sufficient.

2. What is PCBBUY’s plating thickness for PTH rectangle slots?

Standard 20–25 μm copper, customizable per project requirements.

3. What is the minimum slot width supported?

Typically limited by router bit diameter; HDI designs may use laser processing for narrower geometries.

4. How is tolerance controlled?

Dimensional tolerance is maintained through calibrated CNC routing and final 2D metrology inspection.

5. Can rectangle slots affect PCB structural strength?

Yes, especially in thin PCBs. PCBBUY evaluates material selection and slot placement during DFM review.

Industry Category