PCB SMT Assembly Process of Delivers Precision and Reliability

By:PCBBUY 09/28/2025 16:32

In the fast-evolving electronics industry, efficiency, accuracy, and scalability are crucial. The pcb smt assembly process (Surface Mount Technology) has become the preferred method for manufacturing modern electronic products, thanks to its ability to support compact designs and high-volume production. At PCBBUY, we have refined this process to provide customers with consistent quality and competitive value, positioning ourselves as a trusted partner for global electronics companies.

What is PCB SMT Assembly Process?

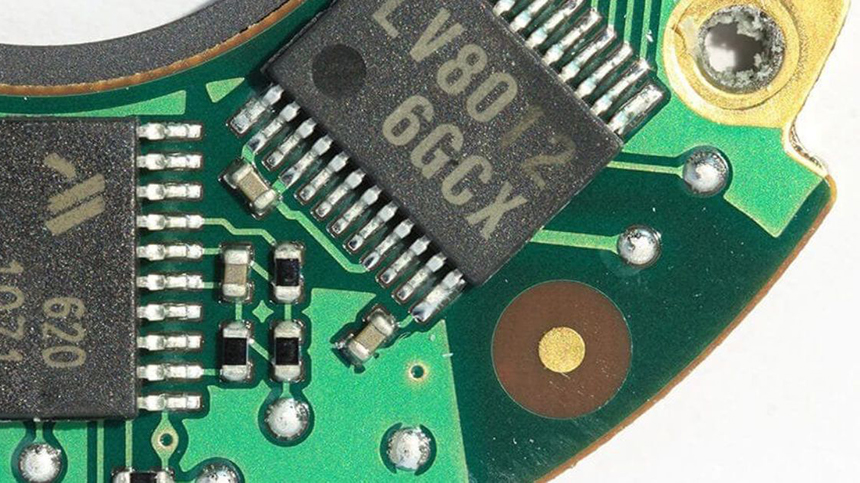

The pcb smt assembly process involves placing electronic components directly onto the surface of a printed circuit board (PCB). Unlike the older Through-Hole Technology (THT), which requires drilling and inserting leads into holes, SMT allows for higher component density and more streamlined production.

This transition from THT to SMT has reshaped electronics manufacturing. From smartphones to medical devices, the demand for smaller, lighter, and more powerful products is only possible thanks to SMT. PCBBUY has invested heavily in mastering this process to deliver reliable solutions for clients worldwide.

Key Steps in the PCB SMT Assembly Process

Every stage of assembly matters. At PCBBUY, each step of the process is carefully controlled to ensure accuracy and reliability.

|

Step |

Process |

How PCBBUY Ensures Quality |

|

1. Solder Paste Printing |

A thin layer of solder paste is applied to the PCB through a laser-cut stencil. |

High-precision printers guarantee even distribution, which is essential for tiny parts like 01005. |

|

2. Pick-and-Place |

Automated machines place components onto the prepared pads. |

Our advanced SMT lines reach up to 80,000 components per hour, with placement accuracy as tight as ±0.02 mm. |

|

3. Reflow Soldering |

The PCB passes through a controlled heating profile to secure the components. |

Carefully designed thermal curves minimize defects such as voids or cold solder joints. |

|

4. Inspection & Testing |

AOI, X-ray, and functional tests verify quality at every stage. |

100% inspection coverage in line with IPC-A-610 standards. |

PCBBUY’s Expertise in PCB SMT Assembly Process

PCBBUY combines advanced machinery with experienced engineering teams. Our capabilities include:

-

Handling fine-pitch components such as BGA, QFN, and CSP packages.

-

Compliance with ISO 9001 and IPC-A-610 Class 2 and Class 3 requirements.

-

Support for both prototype builds and large-scale production.

-

Full turnkey service that covers fabrication, sourcing, assembly, and testing.

This allows us to meet the needs of diverse industries — from consumer electronics to industrial automation and automotive systems.

Benefits of Choosing PCBBUY for PCB SMT Assembly Process

Working with PCBBUY provides tangible advantages:

-

Precision and reliability backed by high-end SMT equipment and skilled staff.

-

Cost savings through optimized material sourcing and streamlined processes.

-

Flexibility to adapt to both small custom runs and mass production orders.

-

Faster lead times with online quoting and efficient production lines.

Challenges in PCB SMT Assembly Process

Like any advanced technology, SMT assembly has its challenges. Issues such as solder bridging, tombstoning, or thermal stress can impact quality. At PCBBUY, we tackle these challenges with:

-

Optimized solder paste formulas and stencil designs.

-

Calibrated pick-and-place systems for accurate component alignment.

-

Strict process monitoring and testing at every step.

The result is a consistent, reliable outcome that minimizes risk for our customers.

Conclusion

The pcb smt assembly process is the backbone of modern electronics manufacturing. With advanced equipment, strict quality management, and years of experience, PCBBUY delivers results that align with international standards and customer expectations. Whether you’re developing a prototype or scaling up to mass production, PCBBUY is the partner you can count on for reliability, efficiency, and excellence.

FAQ: PCB SMT Assembly Process

Q1: What is the main difference between SMT and THT assembly?

SMT places components directly on the board surface, while THT involves drilling holes for component leads. SMT supports higher density and faster production, which is why it’s used in most modern electronics.

Q2: How does PCBBUY ensure quality during the pcb smt assembly process?

We use automated optical inspection (AOI), X-ray inspection, and functional testing at multiple stages, all following IPC-A-610 standards. This ensures consistent, defect-free assemblies.

Q3: Can PCBBUY handle urgent prototype orders?

Yes. Our flexible production lines and online quoting system allow us to deliver both small-batch prototypes and large-scale runs with quick turnaround times.

Industry Category